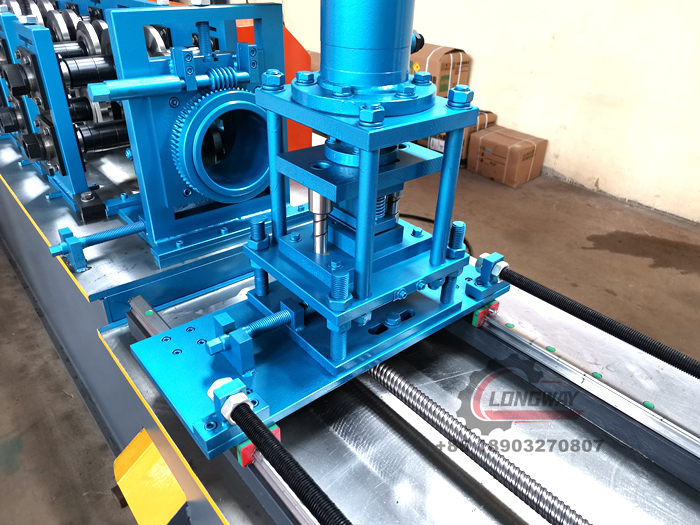

c and z purlin machine factory

Understanding C and Z Purlin Machines A Key Component in Modern Construction

In the ever-evolving world of construction, efficiency and innovation play pivotal roles in the success of any project. One of the unsung heroes in this domain is the C and Z purlin machine, a vital tool in the production of purlins used for structural support in buildings. These machines have revolutionized how construction materials are manufactured, leading to enhanced structural integrity, reduced costs, and faster project completion times.

C and Z purlins are crucial components in modern building frameworks. They are primarily used in the construction of steel structures, providing essential support for roofs and walls. Their shapes—C and Z—are designed to accommodate different load requirements and are used based on specific structural needs. For instance, C purlins are often used for buildings with lighter loads and fewer spans, while Z purlins can handle heavier loads and longer spans due to their interlocking capability.

Understanding C and Z Purlin Machines A Key Component in Modern Construction

One significant advantage of using a C and Z purlin machine is its ability to reduce material waste. Traditional manufacturing methods often result in excessive scrap material, which can drive up costs and impact project timelines. With precise cutting and shaping capabilities, modern purlin machines optimize material usage, delivering a cost-effective manufacturing solution. This efficiency not only benefits manufacturers but also translates into savings for construction companies.

c and z purlin machine factory

Moreover, the integration of computer numerically controlled (CNC) technology in C and Z purlin machines has taken automation to the next level. CNC machines allow for intricate designs and complex shapes, providing the flexibility needed in modern architecture. With real-time monitoring and adjustments, these machines ensure that every product meets stringent quality standards, which is imperative for safety in construction.

Another aspect where these machines shine is in speeding up the construction process. With the ability to produce purlins rapidly, builders can move forward with their projects without delays typically caused by waiting for materials to arrive. This speed contributes to a shorter construction timeline, benefiting clients and ensuring that projects remain within budget and on schedule.

As the construction industry continues to advance, the importance of C and Z purlin machines cannot be overstated. Their ability to enhance efficiency, reduce waste, and ensure quality makes them indispensable for modern construction. For builders and engineers looking to optimize their projects, investing in a high-quality C and Z purlin machine is a forward-thinking decision that aligns with industry trends toward automation and sustainability.

In conclusion, C and Z purlin machines represent a technological leap in construction manufacturing. Their role in producing essential structural components efficiently, safely, and with minimal waste is a testament to the progress being made within the industry. As we look to the future, the continued evolution of these machines will undoubtedly play a critical role in shaping the landscapes of our buildings and infrastructures.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025