c and z purlin machine

Understanding C and Z Purlin Machines Efficiency in Modern Construction

In recent years, the construction industry has seen a significant evolution in the types of materials and machinery used to improve efficiency and reduce costs. One of the essential components in modern structural engineering is purlins, specifically C and Z purlins. These components are integral to the framework of various structures, particularly in steel buildings, warehouses, and workshops. The introduction of advanced C and Z purlin machines has transformed how these essential elements are produced, ensuring consistency, strength, and precision in manufacturing.

The Importance of C and Z Purlins

C and Z purlins are critical in providing structural support to roofs and walls in steel constructions. The design of these purlins allows for efficient load distribution and enhances the overall strength of the building. C purlins, which feature a C-shaped cross-section, are typically used for supports and are advantageous because they can be easily connected with other structural components. Z purlins, with their Z-shaped profile, provide a similar function but are often used in conjunction with one another, offering enhanced stability.

The choice between C and Z purlins often depends on the specific requirements of a project, such as load capacity and design specifications. By utilizing advanced manufacturing techniques, construction projects can benefit from the efficiency these components offer, leading to faster completion times and reduced material waste.

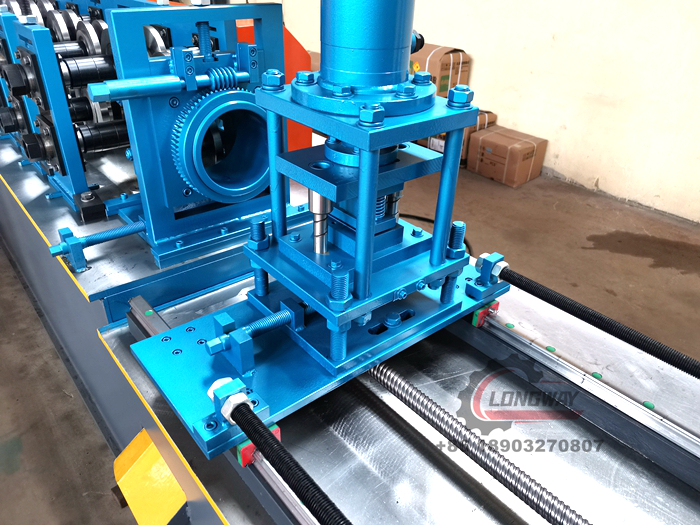

The Role of C and Z Purlin Machines

C and Z purlin machines are specialized equipment designed to produce purlins at an impressive speed while maintaining high-quality standards. These machines have engineered systems that allow for the continuous forming of steel into the required shapes.

1. Capabilities and Features Modern purlin machines are equipped with various features that enhance their functionality. They can typically handle high-speed production lines, allowing for the efficient manufacturing of purlin materials in bulk. With the ability to adjust sizes and shapes according to the specifications required, these machines offer a high level of flexibility, accommodating various project needs.

c and z purlin machine

2. Automation and Precision Advanced technology in C and Z purlin machines means that many processes are automated. This automation not only increases productivity but also reduces human error. Precise cutting, punching, and bending operations are executed automatically, ensuring that every purlin produced meets stringent quality standards. This precision is crucial in construction, where even minor discrepancies can have significant consequences for structural integrity.

3. Material Efficiency One of the main advantages of these machines is their ability to optimize the use of materials. By reducing waste during the manufacturing process, C and Z purlin machines help businesses save on raw materials and costs. Moreover, many machines are designed to work with different types of steel, providing versatility in material selection.

Applications in Construction

The applications of C and Z purlins are varied and broad. They are commonly used in agricultural buildings, commercial warehouses, and industrial sheds. With the ongoing trend towards prefabricated buildings, the use of C and Z purlins has become even more prevalent. Structural engineers and architects rely on the reliability of purlin systems to design safer, cost-effective buildings that can withstand local environmental conditions.

Moreover, the ability to produce purlins rapidly allows contractors to streamline the construction schedule. With the availability of C and Z purlin machines, the construction industry can respond quickly to project demands, ensuring that deadlines are met without compromising quality.

Conclusion

As the construction industry continues to advance, the role of C and Z purlin machines will become increasingly significant. By providing high-quality, precision-engineered purlins efficiently, these machines not only enhance the structural integrity of buildings but also contribute to cost reduction and faster project completion. The ongoing development in purlin manufacturing technology promises to keep pace with the evolving demands of the modern construction industry, highlighting the essential connection between machinery and sustainable building practices.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025