c and z purlin machine

The Advantages of C and Z Purlin Machines in Modern Construction

In the realm of construction and steel fabrication, C and Z purlin machines have emerged as invaluable tools for producing high-quality structural components. These machines are specifically designed to shape steel into C and Z profiles, which are essential for various applications in buildings, warehouses, and other structures. This article explores the features, benefits, and significance of C and Z purlin machines in contemporary construction practices.

Understanding C and Z Purlins

C and Z purlins are secondary structural elements typically used to support roof and wall cladding in buildings. The C shape allows for rigidity and strength, making it suitable for applications where load-bearing is critical. Similarly, the Z profile offers versatility in connecting various structural components, providing efficient load distribution. Both shapes are ideal for creating robust frameworks that are lightweight yet durable, which is essential in modern construction.

Features of C and Z Purlin Machines

C and Z purlin machines are highly specialized tools that feature advanced technology for efficient production. These machines typically include

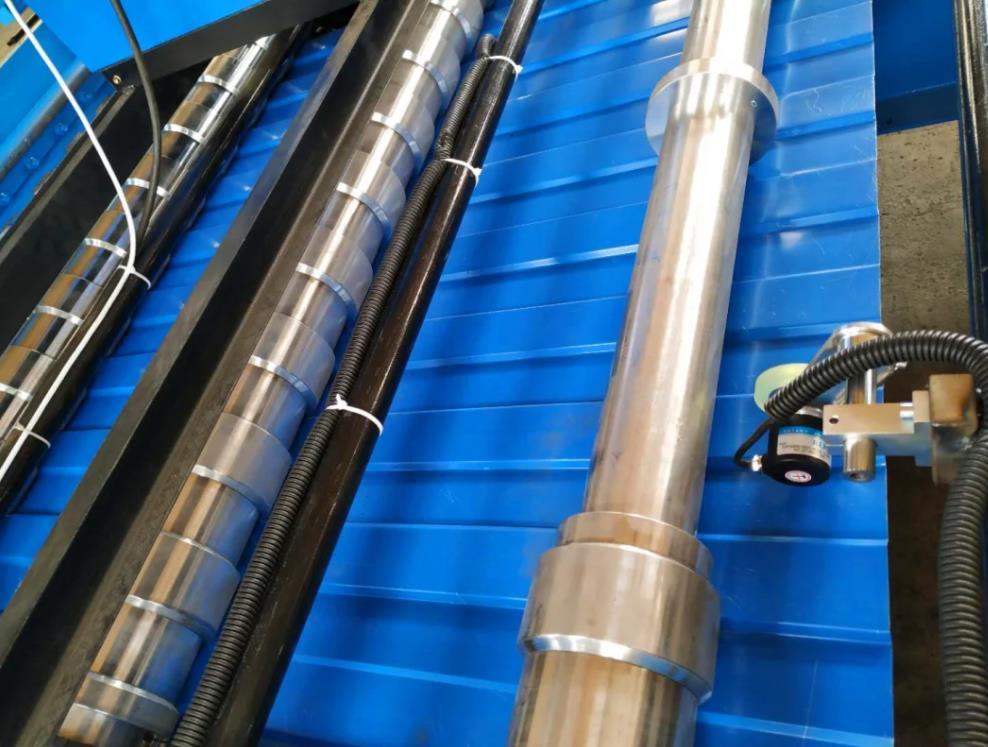

1. Rolling and Forming Capabilities The machines are equipped with rolling mills that form steel strips into C and Z shapes, ensuring precision and uniformity.

3. Automated Control Systems Technological advancements have led to the integration of automated systems, which improve the production speed and reduce human error.

c and z purlin machine

4. Durability and Reliability Constructed with high-quality materials, C and Z purlin machines offer longevity and consistent performance, essential for meeting construction demands.

Benefits of Using C and Z Purlin Machines

1. Cost-Effectiveness By utilizing automated processes and efficient designs, C and Z purlin machines significantly reduce labor costs. They also minimize material waste, leading to overall project cost savings.

2. Time Efficiency With the ability to produce multiple profiles quickly, these machines enhance productivity on construction sites. Fast turnaround times are critical, particularly in large-scale projects where delays can be costly.

3. Customization C and Z purlin machines allow for customization to meet specific project requirements. This flexibility is critical for architects and engineers who require tailored solutions for unique designs.

4. Enhanced Quality The precision engineering capabilities of these machines ensure that the produced purlins meet stringent quality standards, promoting structural integrity and safety in construction projects.

5. Sustainability The ability to produce lightweight yet strong purlins contributes to sustainable building practices. Using C and Z profiles can reduce the overall weight of structures, leading to lower material usage and energy consumption.

Conclusion

The advent of C and Z purlin machines has revolutionized the construction industry by providing effective solutions for producing essential structural elements. Their combination of efficiency, cost-effectiveness, customization, and high-quality output makes them indispensable in modern construction practices. As the industry continues to evolve, these machines will play a crucial role in shaping the future of building, ensuring that structures are not only resilient and sustainable but also meet the diverse needs of a growing population. Thus, investing in C and Z purlin machines presents a strategic advantage for fabricators and constructors aiming to thrive in a competitive market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025