box profile roll forming machine

The Box Profile Roll Forming Machine Enhancing Efficiency in Metal Fabrication

In the dynamic world of metal fabrication, the box profile roll forming machine stands out as a pivotal piece of equipment. This innovative machine is specifically designed to produce box profiles, which are widely used in construction, automotive, and various industrial applications. With its ability to transform flat metal sheets into intricate and precise shapes, the box profile roll forming machine enhances efficiency and elevates product quality in manufacturing processes.

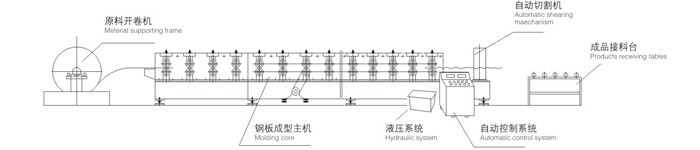

The fundamental principle behind the box profile roll forming machine is continuous shaping. The machine consists of a series of rollers that progressively bend and contour metal strips into the desired box profile. This process begins with a flat sheet or coil of metal, typically made of steel or aluminum. As the metal passes through the rollers, it undergoes a series of precise bends that create the characteristic shape associated with box profiles.

One of the most significant advantages of using a box profile roll forming machine is its high production efficiency. The machine can operate at impressive speeds, allowing manufacturers to produce large quantities of box profiles in a short amount of time. This efficiency not only reduces manufacturing costs but also meets the increasing demands of modern construction projects and other industries.

box profile roll forming machine

Moreover, the box profile roll forming machine is renowned for its precision. The advanced design of the rollers ensures that each profile produced is consistent in dimensions and quality. This precision is crucial, as small variations can lead to structural weaknesses in applications such as building frames or automotive components. With automated systems and computer numerical control (CNC) technology, manufacturers can achieve high levels of accuracy and repeatability, further enhancing the reliability of the produced profiles.

In addition to efficiency and precision, modern box profile roll forming machines also offer versatility. They can be adapted to produce various shapes and sizes of profiles, catering to different client specifications and project requirements. This flexibility allows manufacturers to diversify their product offerings and stay competitive in an ever-evolving market.

In conclusion, the box profile roll forming machine is an essential tool in the metal fabrication industry. It combines efficiency, precision, and versatility, making it ideal for producing box profiles that meet the diverse needs of various sectors. As technology continues to advance, these machines will undoubtedly play an increasingly vital role in shaping the future of metal manufacturing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025