Feb . 11, 2025 14:25

Back to list

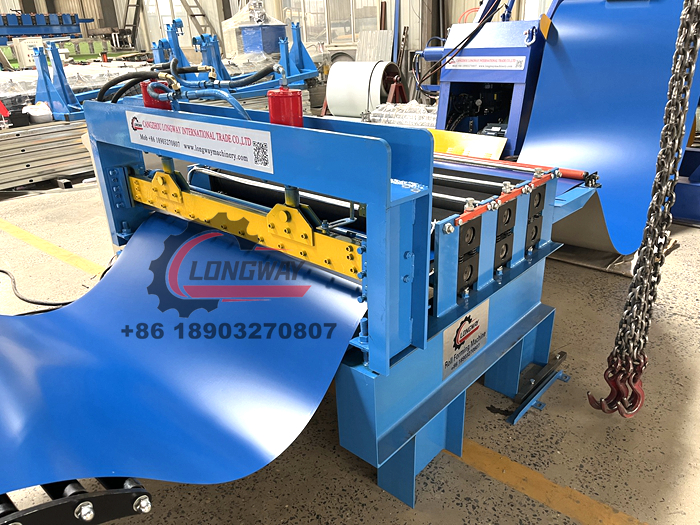

best cold roll forming machine

When it comes to selecting the best cold roll forming machine, distinguishing between mere functionality and outstanding performance is key. As an expert in metal forming processes with extensive hands-on experience, I've navigated the diverse world of machinery to share insights that ensure your investment is both strategic and rewarding.

In terms of authority, it is essential to trust manufacturers known for their expertise and innovation. Brands that continue to push the boundaries of machine engineering often lead the pack in providing superior cold roll forming solutions. Certifications and adherence to international standards are non-negotiable guarantees of a machine’s credibility and performance capabilities. Bear in mind the supplier's reputation and after-sales service quality—they are as crucial as the machine itself. Moreover, transition to digital advancements should be seamless. Equipped with IoT capabilities, the best machines offer remote monitoring and diagnostics. This feature is indispensable for predictive maintenance, ensuring minimal downtime and constant production flow. The integration of such smart solutions exemplifies a move towards modernized, efficient manufacturing environments. Trustworthiness of a cold roll forming machine supplier cannot be overstated. Reliable suppliers offer comprehensive warranties and support. Their willingness to provide training, resources, and technical support is indicative of commitment to customer satisfaction. Over my career, I've witnessed firsthand the advantages of solid supplier relationships, which include reducing unforeseen costs and enhancing operational knowledge. In conclusion, selecting the best cold roll forming machine is a complex decision that demands a careful balance of experience, expertise, reliability, and forward-thinking. By concentrating on machines that promise adaptability, efficiency, durability, and supported by trusted manufacturers, you can position your business for lasting success in the competitive metal forming industry. Embarking on this path with informed decisions not only optimizes your current production process but also solidifies a foundation for scaling and innovation in future operations.

In terms of authority, it is essential to trust manufacturers known for their expertise and innovation. Brands that continue to push the boundaries of machine engineering often lead the pack in providing superior cold roll forming solutions. Certifications and adherence to international standards are non-negotiable guarantees of a machine’s credibility and performance capabilities. Bear in mind the supplier's reputation and after-sales service quality—they are as crucial as the machine itself. Moreover, transition to digital advancements should be seamless. Equipped with IoT capabilities, the best machines offer remote monitoring and diagnostics. This feature is indispensable for predictive maintenance, ensuring minimal downtime and constant production flow. The integration of such smart solutions exemplifies a move towards modernized, efficient manufacturing environments. Trustworthiness of a cold roll forming machine supplier cannot be overstated. Reliable suppliers offer comprehensive warranties and support. Their willingness to provide training, resources, and technical support is indicative of commitment to customer satisfaction. Over my career, I've witnessed firsthand the advantages of solid supplier relationships, which include reducing unforeseen costs and enhancing operational knowledge. In conclusion, selecting the best cold roll forming machine is a complex decision that demands a careful balance of experience, expertise, reliability, and forward-thinking. By concentrating on machines that promise adaptability, efficiency, durability, and supported by trusted manufacturers, you can position your business for lasting success in the competitive metal forming industry. Embarking on this path with informed decisions not only optimizes your current production process but also solidifies a foundation for scaling and innovation in future operations.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products