Batten Roll Forming Machine Supplier for Efficient Roof and Wall Solutions

Understanding Batten Roll Forming Machines A Comprehensive Overview

In the realm of manufacturing, efficiency, precision, and quality are paramount, especially in industries that rely on metal products. Among the various techniques employed to achieve these objectives is the roll forming process, particularly through the use of batten roll forming machines. This article aims to explore the significance, functionality, and advantages of batten roll forming machines, as well as the key characteristics to consider when selecting a manufacturer.

What is Batten Roll Forming?

Batten roll forming is a specialized process used to create long lengths of metal sections, typically from flat coils of metal. The batten, a lightweight, elongated strip, serves a key structural and aesthetic role in various applications, most notably in roofing, cladding, and fencing. The roll forming machine progressively shapes the metal into the desired profile through a series of rollers, which impose specific angles and contours on the material.

The versatility of batten roll forming machines makes them an invaluable asset in the production of building materials. By adjusting the design of the rollers, manufacturers can produce a wide range of profiles that meet specific industry standards or customer requirements. This customization capability allows for innovation in design, leading to improved functionality in building applications.

Key Benefits of Batten Roll Forming Machines

1. Efficiency Batten roll forming machines are designed for high-speed production. The continuous nature of the rolling process minimizes waste and maximizes output. As a result, manufacturers can achieve significant savings in material costs while meeting production timelines.

2. Precision and Consistency These machines provide outstanding dimensional accuracy, which is critical in ensuring that the batten pieces fit seamlessly into their intended applications. The uniformity achieved through roll forming means that quality control can be maintained throughout the production run.

3. Durability Products made through the roll forming process are known for their robustness and long-lasting attributes. The technique enhances the material properties of metals, providing strength and resistance to various environmental factors.

4. Customization Batten roll forming machines can easily be adjusted to produce various profiles, making them highly adaptable to changing market demands. Manufacturers can develop specific profiles that cater to architectural trends or functional requirements.

batten roll forming machine manufacturer

5. Environmentally Friendly Roll forming is an efficient process that can lead to reduced waste. The ability to recycle scrap material further enhances its sustainability, making it an eco-friendly option in the manufacturing of metal products.

Choosing the Right Manufacturer

When seeking a batten roll forming machine manufacturer, several key factors should be considered to ensure that your investment yields the best results

1. Experience and Expertise Look for manufacturers with a proven track record in the industry. Their experience will often correlate with their ability to deliver high-quality machines and exceptional service.

2. Technical Support and Service A reputable manufacturer should provide comprehensive customer support, including installation, training, and ongoing maintenance. This ensures that your machine operates smoothly and efficiently over its lifespan.

3. Customization Options Since projects often have unique requirements, selecting a manufacturer that offers bespoke solutions can give you a significant advantage. Custom rollers and machine configurations can cater to specialized production needs.

4. Quality Assurance Ensure the manufacturer adheres to quality standards and has certifications that demonstrate their commitment to producing reliable, high-performance machinery.

5. Cost-Effectiveness While price shouldn't be the only deciding factor, it is essential to balance cost with the quality and features offered. An initial higher investment can often lead to greater savings and efficiency down the line.

Conclusion

Batten roll forming machines represent an essential tool in modern manufacturing, particularly in construction and related industries. Their efficiency, precision, and adaptability make them invaluable for producing high-quality batten profiles. By carefully selecting a manufacturer that meets your specific requirements, you can significantly enhance your production capabilities and ensure that your products stand out in a competitive market. With the ongoing advancements in technology and the growing emphasis on sustainability, the future for batten roll forming is not only promising but vital to the evolution of the manufacturing landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

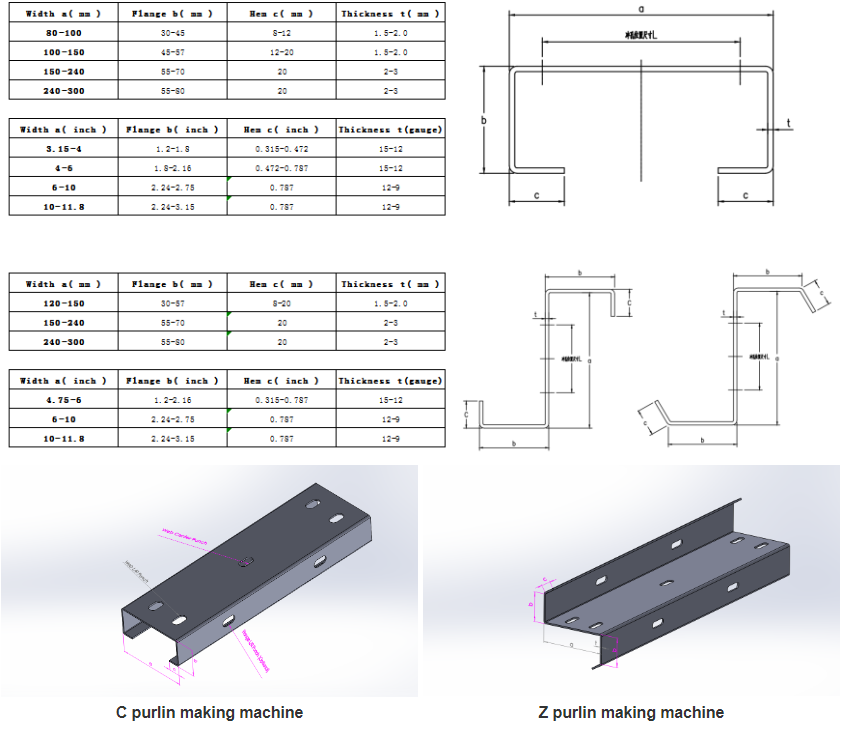

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025