Feb . 11, 2025 08:28

Back to list

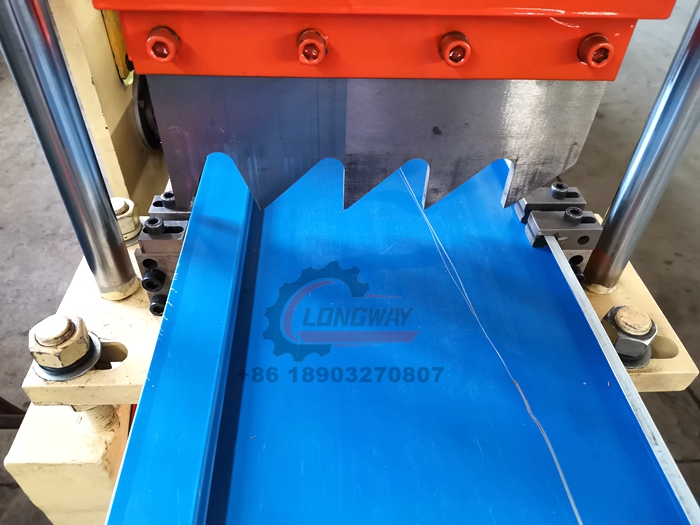

automatic t grid roll forming machine

The ever-evolving industrial landscape has seen a tremendous shift towards automation, with technology playing a crucial role in enhancing efficiency and precision. One such innovation making waves is the automatic T grid roll forming machine. Known for its cutting-edge capabilities, this machine stands at the forefront of modern manufacturing processes, particularly in the production of suspended ceiling grids. By delving into its practical application, expert design, authoritative efficiency, and trustworthy performance, we unveil the essence and significance of this innovative machinery.

Authoritativeness in the market is an inherent attribute of manufacturers who produce these machines, bolstered by their unwavering commitment to quality and innovation. Leading manufacturers have invested substantial resources in research and development to stay ahead in a competitive market. By adhering to international standards and implementing rigorous testing protocols, these companies offer machinery that not only meets but often exceeds customer expectations. The incorporation of advanced technology such as Computer Numerical Control (CNC) systems further accentuates their leadership in the industry. These systems allow for precise machining and forming of grids, ensuring unparalleled accuracy and detail—a critical factor for large-scale commercial or architecturally-sensitive projects. Trustworthiness is built through consistent performance and reliability, two hallmarks of the automatic T grid roll forming machine. When investing in machinery, manufacturers seek assurance that their equipment will function optimally under high demand and various operational environments. The robust construction of these machines ensures longevity, while regular maintenance contributes to sustained performance over years of operation. This machine’s reliability is further evidenced by customer testimonials and case studies, which highlight significant improvements in production timelines and product quality from companies implementing its use. In a market where consistency and quality are scrutinized, these machines stand out as trusted partners in production. In conclusion, the automatic T grid roll forming machine represents a pinnacle of modern engineering in the manufacturing sector. Its ability to seamlessly integrate advanced technology in the production process provides manufacturers with a competitive edge, highlighted by enhanced productivity, cost-effectiveness, and superior product quality. For stakeholders in the construction and manufacturing industries, incorporating this machine means more than just an equipment upgrade—it signifies a step towards operational excellence and future-proofing their production capabilities. Embracing such an advanced technological solution not only positions companies as leaders in their field but also champions the continuous drive for innovation and excellence in manufacturing.

Authoritativeness in the market is an inherent attribute of manufacturers who produce these machines, bolstered by their unwavering commitment to quality and innovation. Leading manufacturers have invested substantial resources in research and development to stay ahead in a competitive market. By adhering to international standards and implementing rigorous testing protocols, these companies offer machinery that not only meets but often exceeds customer expectations. The incorporation of advanced technology such as Computer Numerical Control (CNC) systems further accentuates their leadership in the industry. These systems allow for precise machining and forming of grids, ensuring unparalleled accuracy and detail—a critical factor for large-scale commercial or architecturally-sensitive projects. Trustworthiness is built through consistent performance and reliability, two hallmarks of the automatic T grid roll forming machine. When investing in machinery, manufacturers seek assurance that their equipment will function optimally under high demand and various operational environments. The robust construction of these machines ensures longevity, while regular maintenance contributes to sustained performance over years of operation. This machine’s reliability is further evidenced by customer testimonials and case studies, which highlight significant improvements in production timelines and product quality from companies implementing its use. In a market where consistency and quality are scrutinized, these machines stand out as trusted partners in production. In conclusion, the automatic T grid roll forming machine represents a pinnacle of modern engineering in the manufacturing sector. Its ability to seamlessly integrate advanced technology in the production process provides manufacturers with a competitive edge, highlighted by enhanced productivity, cost-effectiveness, and superior product quality. For stakeholders in the construction and manufacturing industries, incorporating this machine means more than just an equipment upgrade—it signifies a step towards operational excellence and future-proofing their production capabilities. Embracing such an advanced technological solution not only positions companies as leaders in their field but also champions the continuous drive for innovation and excellence in manufacturing.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products