automatic steel sheet slitting line

Automatic Steel Sheet Slitting Line Enhancing Efficiency and Precision in Metal Processing

The steel industry continues to evolve with advancements in technology aimed at increasing efficiency, precision, and safety in metal processing

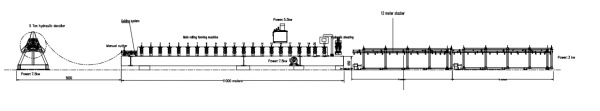

. Among these innovations, the automatic steel sheet slitting line has emerged as a vital piece of equipment for steel manufacturers and fabricators, revolutionizing the way steel sheets are handled and transformed into usable strips.A steel sheet slitting line is designed to convert wide steel coils into thinner strips with varying widths according to the specific requirements of customers. The automatic version of this machinery combines sophisticated technology with automation, resulting in enhanced production rates and minimized labor costs. This line is typically composed of several key components, including uncoilers, slitter heads, tension systems, and recoilers, which work seamlessly together to create high-quality steel strips.

One of the standout advantages of an automatic steel sheet slitting line is its ability to operate with minimal manual intervention. Operators can set the desired specifications through a user-friendly interface, after which the machine takes over, executing precise cuts according to the predetermined measurements. This level of automation significantly reduces the risk of human error, ensuring that the output consistently meets quality standards. Moreover, the automatic systems are designed to quickly adapt to different sizes and shapes, allowing manufacturers to respond rapidly to changing market demands.

Efficiency is another critical benefit offered by automatic slitting lines. These machines can process a wide range of steel grades and thicknesses at high speeds, substantially increasing productivity. In many cases, automated slitting lines can operate up to three times faster than traditional manual setups. This rapid processing capability leads to shorter lead times for customers and allows manufacturers to fill orders more quickly, thereby enhancing their competitive edge in the marketplace.

automatic steel sheet slitting line

In addition to speed and accuracy, the safety features incorporated into automatic slitting lines cannot be overlooked. Modern designs often include safety guards, emergency stop buttons, and advanced monitoring systems that ensure the safety of operators while maintaining high productivity levels. Automated machines can also reduce the physical strain on workers, as they handle strenuous tasks such as lifting and moving heavy steel coils, thereby fostering a safer work environment.

Furthermore, the integration of smart technology into these lines facilitates improved data tracking and management. Manufacturers can monitor production metrics in real time, allowing for better planning and resource allocation. This data-driven approach makes it possible to identify areas for improvement and optimize performance continually.

Sustainability is an increasingly important consideration in modern manufacturing, and automatic slitting lines contribute positively in this regard. The efficiency of these machines not only reduces waste but also lowers energy consumption. By streamlining processes and minimizing resource utilization, companies can reduce their carbon footprint, aligning themselves with global sustainability goals.

In conclusion, the automatic steel sheet slitting line represents a significant advancement in the steel processing industry. Its ability to combine speed, precision, and safety with a focus on sustainability makes it an indispensable tool for manufacturers looking to enhance their operations. As the steel industry continues to innovate, automatic slitting lines will undoubtedly play a pivotal role in shaping the future of metal processing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025