Advanced Precision Slitting Line for Steel Sheet Processing and Automation Solutions

The Advancements in Automatic Steel Sheet Slitting Lines

In recent years, the manufacturing industry has witnessed significant advancements in technology, particularly concerning the processing of metal materials. One of the most revolutionary developments in this field is the automatic steel sheet slitting line. This sophisticated machinery has transformed the way steel sheets are processed by enhancing efficiency, precision, and productivity while reducing labor costs and waste.

Understanding Steel Sheet Slitting Lines

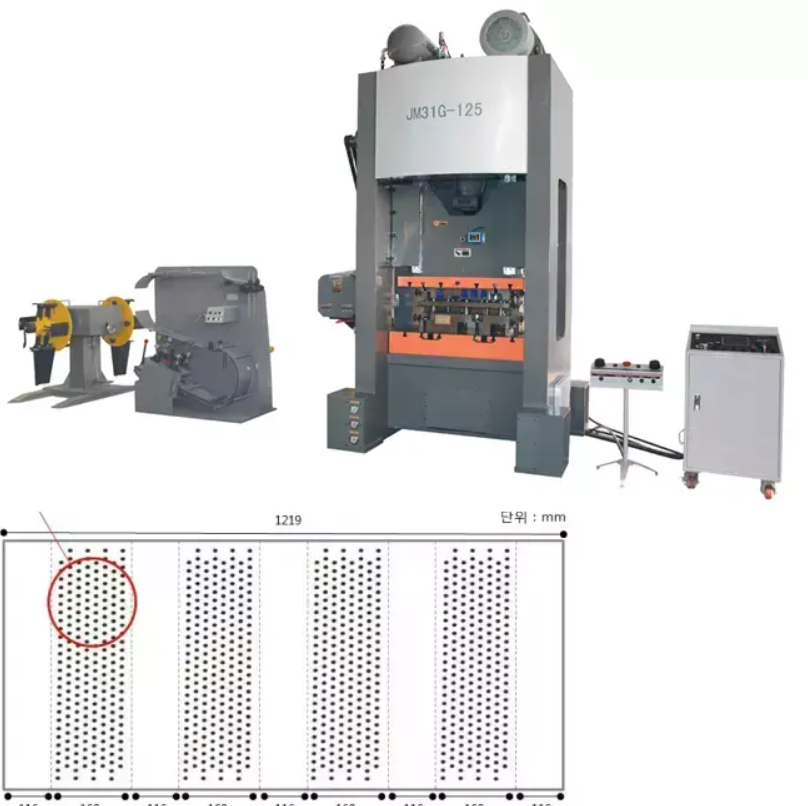

A steel sheet slitting line is a specialized machine designed to cut large rolls of steel sheets into narrower strips of various widths. The slitting process involves several stages, including uncoiling the steel coil, leveling the sheet, slitting it into the desired widths, and recoiling the finished strips. This continuous process is crucial for producing steel components that are used in a wide range of industries, including automotive, construction, and appliance manufacturing.

The Automatic Edge

The primary advantage of an automatic steel sheet slitting line is its automation. Traditional slitting lines often relied heavily on manual labor, which not only increased the risk of human error but also constrained production speed and consistency. Automatic slitting lines are equipped with advanced sensors and control systems that facilitate real-time monitoring of the slitting process. This technology ensures that the operations are performed with remarkable accuracy, resulting in a higher quality of finished products.

Furthermore, with automation, the overall production time is significantly reduced. These systems can operate continuously with minimal downtime, which translates to increased output and profitability for manufacturers. In addition, the automatic processes minimize the risk of operational hazards, which enhances safety in the workplace.

Precision Engineering

automatic steel sheet slitting line

Precision is a critical requirement in steel processing. The capability of an automatic steel sheet slitting line to produce strips of steel within tight tolerances is a game changer. Advanced cutting tools, aligned with high-end software, enable manufacturers to fine-tune the width of each strip with remarkable accuracy. This precision not only meets industry specifications but also caters to the unique requirements of customers.

The integration of Computer Numerical Control (CNC) technology into slitting lines further elevates their performance. CNC systems allow for the programming of specific slitting patterns, enabling quick adjustments for different steel grades and gauge thicknesses. This flexibility ensures that manufacturers can swiftly respond to market changes and customer demands without incurring additional costs.

Sustainability and Waste Reduction

In modern manufacturing, sustainability is a crucial consideration. Automatic steel sheet slitting lines are designed with waste reduction in mind. By using precise cutting methods, these lines minimize scrap material generated during the slitting process. Additionally, the ability to process various materials efficiently contributes to more sustainable production practices.

Energy efficiency is another salient feature of modern slitting lines. Manufacturers are increasingly adopting energy-efficient technologies that reduce power consumption, further contributing to a greener manufacturing environment. This focus on sustainability not only benefits the environment but also aligns with the growing consumer preference for eco-friendly products.

Conclusion

The automatic steel sheet slitting line represents a significant leap forward in the metal processing industry. By combining automation, precision engineering, and sustainability, these systems have redefined the standards of efficiency in steel sheet processing. As industries continue to demand higher quality products and faster turnaround times, the innovations brought forth by automatic slitting lines will remain essential in meeting these evolving challenges, ensuring a competitive edge in the global market. The future of steel processing is undoubtedly bright, driven by advancements that promise to enhance productivity while preserving quality and promoting sustainability.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025