automatic roll forming machine companies

The Rise of Automatic Roll Forming Machine Companies

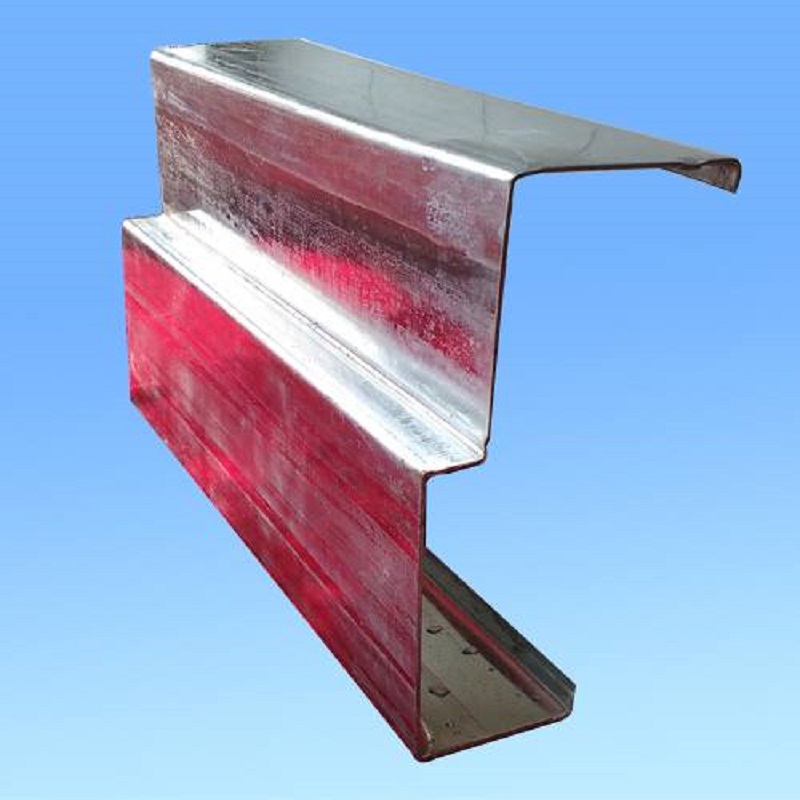

In recent years, the manufacturing sector has witnessed a significant transformation, largely driven by technological advancements and the increasing demand for efficiency and precision. Among these advancements, automatic roll forming machines have carved out a vital niche. These machines are designed to convert flat metal sheets into various shapes and profiles through a continuous bending process, making them indispensable in industries ranging from construction to automotive.

Automatic roll forming machine companies have emerged as key players in this segment, providing innovative solutions that enhance productivity while reducing labor costs. These companies leverage cutting-edge technology, including computer numerical control (CNC) and automation, to improve both the quality and speed of the roll forming process. This shift toward automation not only allows for higher production rates but also minimizes human error, ensuring consistency and precision in every output.

One of the primary advantages of choosing an automatic roll forming machine is the ability to produce complex shapes quickly and with minimal labor. Traditional roll forming often requires significant manual intervention, which can lead to variances in quality and increased production times. Automatic machines streamline this process by employing advanced controls and robotics to handle various stages of production, thereby allowing manufacturers to respond swiftly to market demands.

automatic roll forming machine companies

Moreover, automatic roll forming machines are engineered for versatility. Many companies offer customizable solutions, enabling clients to tailor the machines to their specific needs and requirements. This adaptability is particularly beneficial for companies that need to produce a diverse range of products or that operate in multiple sectors. With the ability to switch between different profiles seamlessly, businesses can save time and resources while maximizing their output.

Furthermore, the advancements in materials technology have allowed automatic roll forming machine companies to expand their offerings. As new materials, such as high-strength steel and aluminum alloys, become popular in manufacturing, these companies innovate their machinery to accommodate varying material properties. This flexibility is vital for industries like automotive manufacturing, where performance and weight efficiency are critical concerns.

The global market for automatic roll forming machines is growing rapidly, driven by the construction boom in emerging economies and the increasing need for energy-efficient solutions. These machines are essential for producing components such as roof trusses, metal studs, and panels, all of which are critical to modern construction projects. Additionally, with the rising focus on sustainable manufacturing practices, many roll forming machine companies are integrating eco-friendly technologies into their operations, further enhancing their appeal in the market.

In conclusion, automatic roll forming machine companies are at the forefront of a manufacturing revolution. Their reliance on automation, customization, and adaptability positions them as vital contributors to efficient production processes across various industries. As technological innovations continue to evolve, these companies are likely to expand their capabilities, pushing the boundaries of what is possible in metal forming. Embracing these advancements not only improves operational efficiency but also prepares businesses to meet the demands of a rapidly changing marketplace. As the industry grows, so too does the potential for future advancements, heralding a new era of precision manufacturing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025