Automatic C Purlin Roll Forming Machine Manufacturing Solutions for Efficient Construction

The Benefits of Automatic C Purlin Roll Forming Machines

In the realm of modern construction and manufacturing, efficiency and precision are paramount. One machine that has risen to meet these demands is the automatic C purlin roll forming machine. This innovative equipment has transformed the way C purlins—essential structural components used in building frameworks—are produced.

C purlins are horizontal structural members that provide support to roofing and wall systems. Traditionally, fabricating C purlins involved manual processes that were time-consuming and prone to errors. However, with the advent of automatic roll forming machines, manufacturers can create these components with remarkable speed and accuracy.

One of the most significant advantages of an automatic C purlin roll forming machine is its efficiency. These machines can produce C purlins in large volumes while reducing labor costs significantly. The automation process minimizes the need for manual intervention, allowing operators to focus on overseeing the production rather than being directly involved in every step. This leads to higher productivity and, ultimately, lower operational costs.

automatic c purlin roll forming machine factory

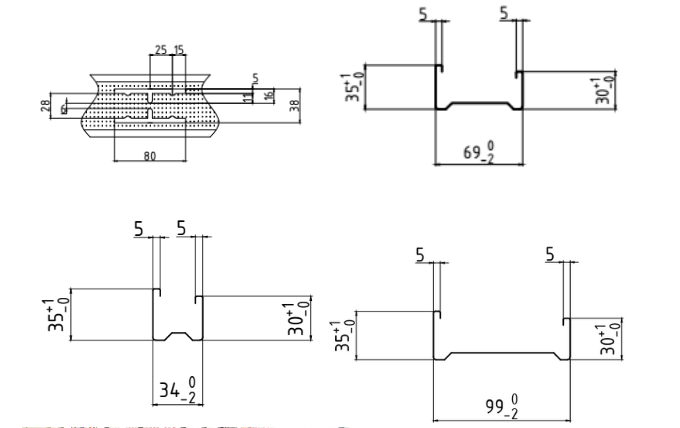

Moreover, the precision offered by automatic roll forming machines cannot be overstated. These machines are designed to produce consistently high-quality purlins that meet stringent industry standards. Advanced control systems ensure that the dimensions and shapes of the purlins are maintained with minimal variations, which is crucial for structural integrity in construction projects. The ability to customize specifications quickly means that different sizes and gauges can be produced on demand, catering to varied construction needs.

Another compelling benefit of these machines is their versatility. Automatic C purlin roll forming machines can be programmed to accommodate different profiles and thicknesses, making them suitable for a wide array of applications beyond traditional construction. Industries such as agriculture, automotive, and even solar energy can leverage these machines to produce specialized components tailored to their specific requirements.

The durability and reliability of automatic C purlin roll forming machines further enhance their appeal. Built with robust materials and advanced engineering, these machines are designed to withstand the rigors of continuous operation. Manufacturers can rely on their performance over extended periods, ensuring a good return on investment.

In conclusion, automatic C purlin roll forming machines are revolutionizing the way structural components are manufactured. With their efficiency, precision, versatility, and durability, they are becoming indispensable tools in the construction industry. As the demand for high-quality, cost-effective building materials continues to rise, the adoption of automatic roll forming technologies is likely to grow, leading to enhanced competitiveness in an ever-evolving market. Investing in such advanced machinery not only boosts productivity but also positions manufacturers at the forefront of innovation in construction materials.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025