Automatic Steel Furring Channel Roll Forming Machine | Precision & Speed

Introduction to Advanced Roll Forming Technology

In the rapidly evolving construction and building materials sector, the demand for precise, high-strength, and cost-effective structural components is paramount. This necessitates advanced manufacturing solutions capable of producing these materials with exceptional consistency and efficiency. Central to this innovation is the Steel Furring Channel roll forming machine. These specialized machines are engineered to transform flat steel coils into intricate furring channel profiles, critical for ceiling, drywall, and cladding applications, providing structural support and leveling surfaces. Our discussion delves into the technical intricacies, market relevance, and operational advantages of this essential equipment, highlighting its role in modern construction.

The construction industry's continuous drive towards optimizing material usage, reducing labor costs, and enhancing structural integrity underscores the significance of automated production lines. A robust Steel Furring Channel roll forming machine offers unparalleled precision, allowing manufacturers to meet stringent international building codes and project specifications. This article will provide a comprehensive overview, from fundamental manufacturing processes to sophisticated customization options, ensuring a deep understanding for B2B decision-makers and technical professionals.

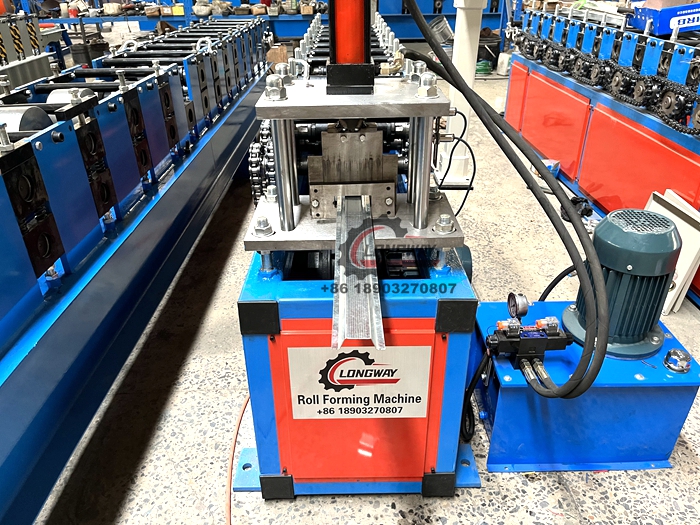

Detailed Process Flow of the Steel Furring Channel Roll Forming Machine

The manufacturing of furring channels using a Steel Furring Channel roll forming machine is a multi-stage, highly automated process designed for efficiency and precision. This section details the sequential steps involved, emphasizing material specifications, key manufacturing operations, quality control, and the resultant advantages.

1. Material Selection and Preparation:

- Product Materials: Typically, galvanized steel coils are used, offering excellent corrosion resistance crucial for long service life in various environments. Common grades include G300, G450, or G550 (tensile strength in MPa), with thicknesses ranging from 0.4 mm to 1.2 mm. Zinc coating mass often adheres to Z180, Z275, or equivalent standards, ensuring durability against moisture and environmental degradation. The choice of material directly impacts the final product's strength-to-weight ratio and cost-effectiveness.

- Coil Loading: The steel coil is loaded onto an uncoiler (decoiler) at the entry of the machine, which then feeds the strip into the initial forming stages.

2. Manufacturing Processes:

- Feeding and Leveling: The steel strip passes through a guiding and leveling system to ensure it is perfectly flat and aligned, preventing material distortion during subsequent forming.

- Punching (Optional): Depending on the furring channel design, specific holes or cutouts for fasteners or service lines may be pre-punched in a dedicated station before the main roll forming. This is often achieved using precision hydraulic or pneumatic punching units controlled by CNC systems for accuracy.

- Roll Forming Stages: This is the core of the process. The strip is progressively shaped by a series of precisely designed rolling dies (roller sets). Each pair of rollers imparts a slight change to the metal's profile, gradually transforming the flat strip into the desired furring channel shape (e.g., hat channel, resilient channel, Z-channel). The number of forming stations can range from 10 to 24 or more, depending on the complexity of the profile and material thickness. The rolls themselves are often made from high-grade tool steel (e.g., Cr12Mov, GCr15), heat-treated to HRC58-62, and precision-machined via CNC for durability and accuracy.

- Cutting-to-Length: Once the final profile is achieved, a high-speed flying shear or hydraulic cutting system precisely cuts the continuous profile to the programmed length without stopping the main forming line. This ensures high production rates.

- Output and Stacking: The cut furring channels are then conveyed to an automatic stacking or collection system, ready for packaging.

3. Testing Standards and Quality Control:

Quality control is integrated throughout the process. Finished products are checked against industry standards such as ASTM C645 (Standard Specification for Nonstructural Steel Framing Members), AS/NZS 4600 (Cold-Formed Steel Structures), and EN 14195 (Drywall Metal Framing Components). Key parameters tested include dimensional accuracy (length, width, height, flange angles), material thickness, zinc coating integrity, and straightness. Advanced machines often incorporate inline measurement systems to detect deviations in real-time.

4. Service Life and Target Industries:

A well-maintained Steel Furring Channel roll forming machine, constructed with high-quality components (e.g., hardened tool steel rolls, robust frame, reliable hydraulics/pneumatics, Siemens/Schneider electrics), can have a service life exceeding 15-20 years with proper operational procedures and preventative maintenance. The primary target industries include:

- Building & Construction: For drywall systems, false ceilings, wall furring, and exterior cladding supports.

- Prefabricated Housing: Providing lightweight structural elements for modular and off-site construction.

- Commercial & Industrial Developments: Large-scale projects requiring standardized, high-volume production of framing components.

- Renovation & Retrofitting: For upgrading existing structures with modern, durable framing solutions.

5. Advantages in Typical Application Scenarios:

- Energy Saving: Modern machines incorporate energy-efficient motors (e.g., IE3 standard) and hydraulic systems, minimizing power consumption per linear meter of production. Optimized roll designs reduce material stress, leading to less energy expended during forming.

- Corrosion Resistance: By processing pre-galvanized steel, the resulting furring channels exhibit inherent corrosion resistance, extending the lifespan of the construction components and reducing maintenance needs in humid or aggressive environments.

- Enhanced Structural Integrity: The precise forming capabilities ensure uniform profiles, leading to consistent load-bearing capacity and overall structural stability in ceiling and wall systems.

- Reduced Waste: Automated cutting and precise material handling minimize scrap rates, contributing to sustainability and cost savings.

Industry Trends and Market Dynamics

The global market for cold roll-formed products, including furring channels, is experiencing steady growth, driven by urbanization, infrastructure development, and an increasing emphasis on sustainable building practices. Several key trends are shaping the future of the Steel Furring Channel roll forming machine industry:

- Automation and Industry 4.0 Integration: Manufacturers are increasingly adopting fully automated lines with IoT capabilities, predictive maintenance, and remote diagnostics. This enhances operational efficiency, reduces human intervention, and optimizes production schedules.

- Increased Demand for High-Strength Steels: To reduce material weight while maintaining structural performance, there's a growing preference for higher-grade galvanized steels (e.g., G550). This requires roll forming machines capable of handling higher yield strength materials without compromising profile accuracy or tool life.

- Customization and Profile Complexity: Architectural designs are becoming more intricate, leading to a demand for machines that can produce a wider variety of furring channel profiles, including those with unique stiffening ribs, dimples, or complex bends. Quick-change tooling systems are becoming essential.

- Energy Efficiency and Sustainability: Beyond materials, the operational efficiency of the machines themselves is a key focus. Developments include more efficient drive systems, waste heat recovery, and intelligent energy management, aligning with green building initiatives.

- Global Market Expansion: Emerging economies, particularly in Asia-Pacific and Africa, are witnessing significant growth in construction, creating new markets for steel framing components and the machines that produce them.

These trends underscore the importance of investing in modern, adaptable roll forming technology to stay competitive and meet evolving market demands.

Technical Specifications and Parameters

A detailed understanding of the technical specifications of a Steel Furring Channel roll forming machine is crucial for procurement and operational planning. The following table outlines typical parameters, though these can vary based on specific models and customization requests.

Product Specification Table: Steel Furring Channel Roll Forming Machine

| Parameter | Specification Range | Typical Value / Details |

|---|---|---|

| Raw Material Thickness | 0.4 mm - 1.2 mm | Galvanized Steel Coil (G300-G550) |

| Forming Speed | 15 m/min - 40 m/min (adjustable) | ~25 m/min (depending on profile & material) |

| Number of Forming Stations | 12 - 24 stations | 18 stations for standard hat channel |

| Main Motor Power | 7.5 kW - 18.5 kW | 11 kW (IE3 efficiency rated) |

| Cutting System | Hydraulic flying shear / Servo motor cutting | Precision cut-to-length (± 1 mm) |

| Roller Material | Cr12Mov, GCr15, 45# steel (quenched) | Cr12Mov, heat-treated to HRC58-62 |

| Control System | PLC with Touch Screen HMI | Siemens S7/Allen-Bradley, Delta/Schneider components |

| Machine Dimensions (L x W x H) | 6 m - 10 m x 1.2 m - 1.8 m x 1.5 m - 1.8 m | ~8 m x 1.5 m x 1.6 m |

| Total Weight | 3.5 Tons - 8 Tons | ~5 Tons |

Technical Advantages and Performance Metrics

Modern Steel Furring Channel roll forming machine systems offer significant technical advantages that translate into superior product quality and operational efficiency. These benefits are critical for manufacturers aiming for high-volume, precision output.

- High Precision and Repeatability: Advanced CNC control systems and precision-machined rollers ensure dimensional accuracy (e.g., ± 0.5mm for profile dimensions) and consistent output, minimizing material waste and ensuring compliance with stringent building codes like ASTM C645 or British Standard BS EN 14195.

- Robust Construction and Durability: Frames fabricated from high-grade structural steel (e.g., H-beam or welded plate steel, stress-relieved after welding) and heavy-duty gearboxes (often helical gear or chain drive) provide exceptional stability and a prolonged operational lifespan, even under continuous heavy-duty use.

- Versatility in Profile Production: Many machines are designed with modular tooling or quick-change cassette systems, allowing for rapid changeovers between different furring channel profiles (e.g., hat channels, Z-channels, resilient channels, C-channels) or even light gauge steel studs/tracks, maximizing production flexibility.

- Optimized Power Consumption: Integration of high-efficiency motors (e.g., IE3 or IE4 standards), intelligent hydraulic systems with variable frequency drives (VFDs), and optimized roll tooling designs significantly reduce energy consumption per meter of product, leading to lower operating costs.

- User-Friendly HMI and Diagnostics: Intuitive human-machine interfaces (HMI) with touch screens allow operators to easily set parameters, monitor production, and access diagnostic tools, reducing training time and enabling faster troubleshooting.

- Integrated Safety Features: Comprehensive safety measures, including emergency stop buttons, safety guarding, light curtains, and overload protection, ensure operator safety and compliance with international machinery safety standards (e.g., CE, OSHA).

- Low Maintenance Requirements: High-quality components, sealed bearings, and centralized lubrication systems reduce the need for frequent maintenance, minimizing downtime and extending component life.

Application Scenarios and Case Studies

The versatility and efficiency of the Steel Furring Channel roll forming machine translate into a wide array of critical applications across various construction sectors. Furring channels produced by these machines are fundamental components in modern building practices.

Typical Application Scenarios:

- Suspended Ceiling Systems: Furring channels form the essential grid work for supporting ceiling panels, providing a level surface and facilitating the integration of lighting and HVAC systems. Their lightweight yet strong profile is ideal for large commercial and institutional spaces.

- Drywall Furring: Used to create a level and plumb surface over masonry, concrete, or irregular existing walls, allowing for the easy installation of gypsum board (drywall). This also creates an air gap for insulation and wiring.

- Exterior Cladding Support: In rainscreen and ventilated façade systems, furring channels provide the sub-framing necessary to attach exterior cladding materials while maintaining an air gap for moisture management and thermal performance.

- Acoustic Isolation: Resilient furring channels are specifically designed with a decoupled connection to reduce sound transmission through walls and ceilings, vital in theaters, studios, and multi-family residential buildings.

- Fire-Rated Assemblies: Steel furring channels are often integral to fire-rated wall and ceiling assemblies, contributing to the structural integrity and fire resistance of the overall system.

Application Case Study: High-Volume Production for a Major Developer

Client: A prominent real estate developer in the Middle East, undertaking multiple large-scale residential and commercial projects concurrently.

Challenge: The developer faced a critical need for a consistent supply of high-quality furring channels (hat-channel and resilient channel profiles) for over 10,000 residential units and 500,000 square meters of commercial space. Previous suppliers struggled with inconsistent quality and lead times, impacting project schedules.

Solution: We provided a customized, high-speed Steel Furring Channel roll forming machine with integrated punching capabilities and an automatic stacking system. The machine was configured to produce both hat and resilient channels from 0.55mm galvanized steel, with a production speed of up to 30 meters per minute.

Outcome:

- On-Time Delivery: The in-house production capability eliminated reliance on external suppliers, allowing the developer to meet aggressive construction timelines.

- Cost Savings: Significant reduction in material acquisition costs (up to 15%) and logistics expenses.

- Superior Quality: Consistent dimensional accuracy (±0.5mm) ensured easier installation and reduced on-site waste, leading to a higher quality finish for drywall and ceilings.

- Operational Efficiency: The automated system required fewer operators and operated with high uptime, demonstrating the machine's reliability and contribution to overall project profitability.

Vendor Comparison and Selection Criteria

Choosing the right manufacturer for a Steel Furring Channel roll forming machine is a strategic decision that impacts long-term operational success. While many vendors offer such machinery, key differentiators exist in technology, support, and overall value.

Key Comparison Factors:

- Technology and Automation Level: Assess the PLC brand (e.g., Siemens, Allen-Bradley), HMI capabilities, presence of closed-loop control systems, and integration options for Industry 4.0.

- Machine Construction and Component Quality: Evaluate the frame material, gearbox type, roller material and heat treatment, and brands of electrical and hydraulic components (e.g., Schneider, Bosch Rexroth). Superior components ensure longevity and consistent performance.

- Production Speed and Flexibility: Compare maximum operating speeds, ease of profile changeovers (manual vs. automatic tooling), and the range of material thicknesses/widths the machine can handle.

- After-Sales Support and Warranty: Look for comprehensive warranty periods (typically 1-2 years), availability of spare parts, remote diagnostics capabilities, and on-site technical support for installation, commissioning, and training.

- Certifications and Standards: Verify that the manufacturer adheres to international standards such as ISO 9001 for quality management and CE marking for European safety compliance.

- Customization Capabilities: A vendor's ability to tailor the machine to specific profile designs, material requirements, or unique factory layouts is a significant advantage.

Vendor Comparison Table (Illustrative):

| Feature | Vendor A (Premium) | Vendor B (Mid-Range) | Vendor C (Budget) |

|---|---|---|---|

| Control System | Siemens S7-1200, intuitive HMI, remote access | Delta/Schneider PLC, standard HMI | Local brand PLC, basic display |

| Roller Material & Hardness | Cr12Mov, HRC58-62, lifetime warranty on rollers | GCr15, HRC55-58, 5-year warranty | 45# steel (quenched), HRC48-52, 1-year warranty |

| Max. Production Speed | 40 m/min | 25 m/min | 15 m/min |

| Changeover Time | < 15 min (cassette system) | ~60 min (manual tooling) | > 90 min (manual, fixed tooling) |

| After-Sales Support | 24/7 remote, global on-site, extensive spare parts | Online support, regional service centers | Limited online support |

Customized Solutions

Understanding that every client has unique requirements, leading manufacturers of the Steel Furring Channel roll forming machine offer extensive customization capabilities. This ensures the machinery integrates seamlessly into existing production lines and meets specific product demands.

- Profile Design and Tooling: Development of bespoke roller sets and cutting dies for unique furring channel profiles (e.g., custom dimpling, specific web perforations, non-standard flange angles) that cater to specialized architectural or structural requirements.

- Material Handling Systems: Integration of advanced uncoiling, guiding, and automatic stacking systems, including multi-coil holders, heavy-duty decoilers for larger coils (up to 15 tons), or automated robotic packaging solutions.

- Speed and Automation Levels: Tailoring machine speed to match desired production volumes, from entry-level semi-automatic systems to fully automated lines with minimal human intervention, often incorporating servo-driven components for enhanced speed and accuracy.

- Punching and Notching Integration: Customization of pre/post-punching units for specific hole patterns, knockouts for electrical conduits, or precision notching for interlocking systems, controlled via programmable logic controllers (PLCs).

- Line Layout and Footprint: Adapting the machine's configuration to fit within constrained factory spaces, including considerations for material flow, maintenance access, and safety zones.

- Control System Features: Custom programming of the HMI for specific language requirements, data logging capabilities for production analysis, and integration with existing factory management systems (MES/ERP).

By collaborating closely with clients from concept to commissioning, expert manufacturers can deliver solutions that are not just machines, but strategic assets designed for long-term operational excellence.

Commitment to Trustworthiness: FAQ, Lead Time, Warranty & Support

Building trust is paramount in B2B relationships. Our commitment extends beyond delivering high-quality machinery to providing comprehensive support throughout the entire lifecycle of your Steel Furring Channel roll forming machine.

Frequently Asked Questions (FAQ):

- Q1: What types of furring channels can this machine produce?

- A1: Our machines are designed to produce various profiles including Hat Channels, Z-Channels, Resilient Channels, and custom profiles. This versatility is often achieved through modular tooling or quick-change cassette systems.

- Q2: What is the typical lead time for a custom machine?

- A2: Standard machine models typically have a lead time of 60-90 business days from order confirmation. For highly customized solutions, lead times can range from 90 to 150 business days, depending on design complexity and component sourcing.

- Q3: What kind of after-sales support is provided?

- A3: We offer comprehensive after-sales support including remote diagnostics via internet connection, telephone/video call support, and on-site technical assistance for installation, commissioning, training, and troubleshooting. A dedicated spare parts department ensures prompt delivery of components.

- Q4: Are your machines compliant with international safety standards?

- A4: Yes, all our machines are designed and manufactured in accordance with international safety standards, including CE certification for the European market and adherence to relevant ASTM and ISO standards where applicable. Safety features such as emergency stops, protective guarding, and overload protection are standard.

Lead Time & Fulfillment Details:

Project fulfillment begins with a detailed engineering design review and client approval. Manufacturing typically commences within 5-7 business days post-approval. Delivery logistics, including crating, shipping, and customs documentation, are meticulously handled to ensure smooth transit and timely arrival at your facility. Expedited options are available upon request and subject to project scope.

Warranty Commitments:

We provide a standard 12-month warranty on all mechanical and electrical components from the date of commissioning or 18 months from shipment, whichever comes first. Extended warranty options are available. Our roller tooling, crafted from high-grade Cr12Mov steel, typically carries a longer warranty against manufacturing defects, highlighting our confidence in its durability and precision.

Customer Support Information:

Our dedicated customer support team is available during business hours via phone and email. For urgent technical issues, a 24/7 emergency hotline is provided to ensure minimal downtime. We also offer annual maintenance contracts (AMCs) that include preventative maintenance checks, software updates, and priority service to maximize machine uptime and performance.

Conclusion

The modern Steel Furring Channel roll forming machine represents a cornerstone of efficiency and precision in the contemporary construction and building materials manufacturing landscape. Its capability to produce high-quality, consistent furring channels from various grades of galvanized steel, coupled with advanced automation and customization options, makes it an indispensable asset for any operation aiming for competitive advantage.

By focusing on robust construction, energy efficiency, and comprehensive after-sales support, leading manufacturers ensure that these machines not only meet but exceed the rigorous demands of global construction projects. Investing in cutting-edge roll forming technology is a strategic move towards enhanced productivity, superior product quality, and long-term operational resilience.

References

- ASTM International. (2023). ASTM C645/C645M, Standard Specification for Nonstructural Steel Framing Members. Retrieved from astm.org

- Eurocodes: Design of steel structures. EN 1993. Part 1-3: General rules – Supplementary rules for cold-formed members and sheeting. (2006). British Standards Institution. Retrieved from standards.org.au

- Cold-Formed Steel Engineers Institute (CFSEI). (2022). Technical Notes & Resources. Retrieved from cfsei.org

- The Fabricator. (2023). Roll Forming for High-Strength Steel. Retrieved from thefabricator.com

- ISO 9001:2015 - Quality management systems - Requirements. (2015). International Organization for Standardization. Retrieved from iso.org

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025