automatic c purlin roll forming machine manufacturer

The Advantages of Automating C Purlin Roll Forming Machines

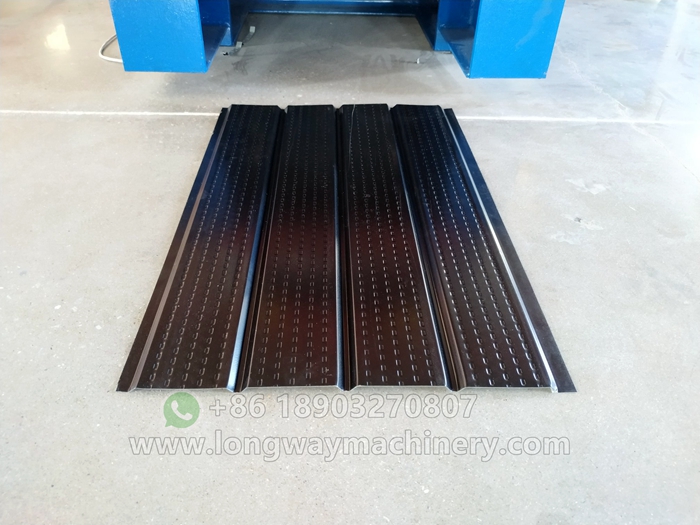

In the modern construction and manufacturing industries, efficiency and precision are paramount. One of the key innovations that have emerged to meet these demands is the automatic C purlin roll forming machine. This advanced machinery is designed to streamline the production of C purlins, essential structural components used in steel frameworks for buildings and other constructions. Here, we explore the advantages of investing in an automatic C purlin roll forming machine, particularly focusing on aspects such as efficiency, consistency, and cost-effectiveness.

Firstly, the primary advantage of an automatic C purlin roll forming machine is its enhanced efficiency. Unlike traditional manual systems, which require substantial human intervention, automatic machines can produce large quantities of purlins with minimal downtime. With automated feeding and cutting processes, these machines can operate continuously, significantly increasing production rates. As a result, businesses can meet high demand without compromising on quality or speed, allowing for quicker project completions.

Moreover, consistency is a critical factor in construction materials. Automatic C purlin roll forming machines deliver uniformity in dimensions and shapes, ensuring that every purlin produced meets stringent quality standards. This consistency reduces the probability of errors that can occur in manual processes, thus minimizing waste and rework. The precision embedded in automatic systems guarantees that builders receive reliable materials, essential for maintaining structural integrity and safety.

automatic c purlin roll forming machine manufacturer

Cost-effectiveness is another significant advantage. While the initial investment in an automatic C purlin roll forming machine may be higher compared to manual alternatives, the long-term savings are substantial. The increase in production efficiency means that companies can reduce labor costs, as fewer operators are needed to run the machines. Additionally, reduced material wastage contributes to lower overall expenses. When businesses calculate the return on investment, they often find that these automatic systems pay for themselves over time through increased output and decreased operational costs.

Furthermore, modern automatic roll forming machines often come equipped with advanced technology, including programmable controls and remote monitoring capabilities. This level of innovation not only allows for versatility in producing various purlin sizes but also facilitates easy adjustments for different project requirements. With the ability to quickly switch between product specifications, manufacturers can respond swiftly to changing market demands.

In conclusion, the adoption of automatic C purlin roll forming machines represents a significant advancement in manufacturing processes. By enhancing efficiency, ensuring consistency, and providing cost-effective solutions, these machines have transformed the way that steel components are produced, enabling businesses to thrive in a competitive market. As the construction industry continues to evolve, investing in such innovative technology is not just an option; it is becoming a necessity for staying ahead.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025