Feb . 11, 2025 01:17

Back to list

arch roof roll forming machine

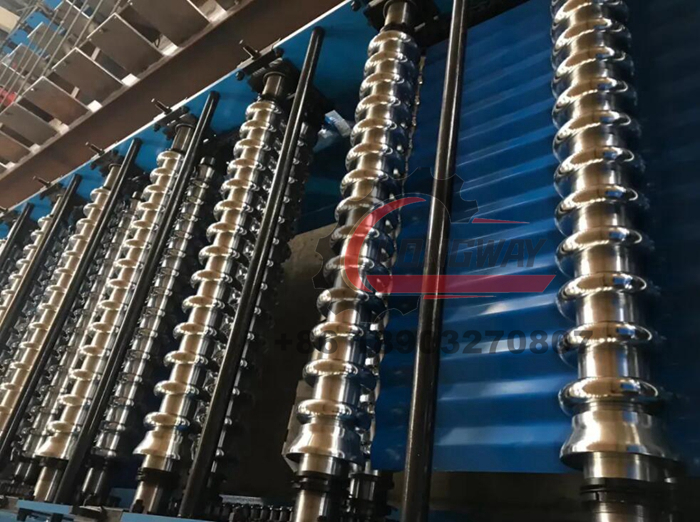

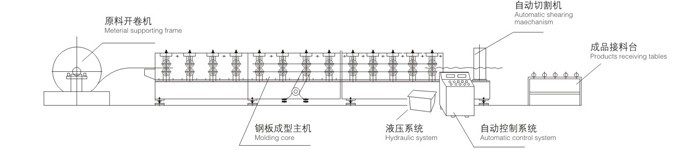

In the modern construction environment, efficiency and precision have become the cornerstones of competitive advantage. The arch roof roll forming machine stands as a testament to how technology can revolutionize building techniques, providing not only structural beauty but also enhancing productivity. To grasp the full potential of these machines, it is essential to delve into their design, efficiency, and benefits from a seasoned perspective grounded in real-world experiences and expert knowledge.

Authoritativeness is affirmed through the industry standards and certifications that arch roof roll forming machines adhere to. Many manufacturers ensure their machines comply with rigorous quality controls and safety regulations, reassuring clients and stakeholders of their dependability. Furthermore, testimonials from construction firms and architectural experts underline the reliability of these machines in creating durable structures capable of withstanding diverse environmental challenges, ranging from high winds to seismic activities. Trustworthiness is built on the transparency and customer support offered by reputable roll forming machine manufacturers. Investing in these machines implies a long-term commitment, making after-sales service and technical support integral to the decision-making process. Leading firms provide extensive training sessions and maintenance guidance to ensure that operators are fully versed in the machine’s capabilities, significantly reducing downtime and operational issues. In conclusion, the adoption of arch roof roll forming machines within the construction sector signifies an evolution towards more resilient, cost-effective, and aesthetically pleasing structures. As contemporary architectural needs grow increasingly complex and varied, these machines offer a reliable solution that is supported by experienced professionals dedicated to advancing construction technology. The symbiotic relationship between cutting-edge machinery and expert knowledge ensures that arch roof roll forming machines will remain pivotal in shaping the future of the construction industry.

Authoritativeness is affirmed through the industry standards and certifications that arch roof roll forming machines adhere to. Many manufacturers ensure their machines comply with rigorous quality controls and safety regulations, reassuring clients and stakeholders of their dependability. Furthermore, testimonials from construction firms and architectural experts underline the reliability of these machines in creating durable structures capable of withstanding diverse environmental challenges, ranging from high winds to seismic activities. Trustworthiness is built on the transparency and customer support offered by reputable roll forming machine manufacturers. Investing in these machines implies a long-term commitment, making after-sales service and technical support integral to the decision-making process. Leading firms provide extensive training sessions and maintenance guidance to ensure that operators are fully versed in the machine’s capabilities, significantly reducing downtime and operational issues. In conclusion, the adoption of arch roof roll forming machines within the construction sector signifies an evolution towards more resilient, cost-effective, and aesthetically pleasing structures. As contemporary architectural needs grow increasingly complex and varied, these machines offer a reliable solution that is supported by experienced professionals dedicated to advancing construction technology. The symbiotic relationship between cutting-edge machinery and expert knowledge ensures that arch roof roll forming machines will remain pivotal in shaping the future of the construction industry.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products