Top Manufacturers of Angle Steel Roll Forming Machinery for Industrial Production

The Role of Angle Steel Roll Forming Machine Manufacturers

In today's competitive construction and manufacturing industries, the efficiency and precision of metal forming processes are paramount. One of the essential processes in these industries is the production of angle steel, which is widely used in various applications, from structural support to frameworks for buildings and bridges. Angle steel roll forming machines serve as a vital tool in this process, and the manufacturers of these machines play a crucial role in shaping the future of construction materials.

Understanding Angle Steel Roll Forming Machines

Angle steel, characterized by its L-shaped cross-section, offers remarkable strength and stability. Roll forming is a continuous bending operation in which a long strip of metal is passed through sets of rolls to achieve the desired cross-section. The angle steel roll forming machine automates this process, allowing for high production rates and consistent quality of the products.

Manufacturers of angle steel roll forming machines design equipment that accommodates various material thicknesses and widths, ensuring adaptability to different production needs. These machines often incorporate advanced technology, such as computer numerical control (CNC) systems, which enhance precision and allow for easy adjustments to specifications.

The Importance of Manufacturers in the Industry

The role of angle steel roll forming machine manufacturers is multifaceted. Firstly, they are responsible for the innovation and development of machines that can meet the ever-evolving demands of the building industry. This includes creating machines that are not only efficient but also versatile enough to produce different types of angle steel profiles.

Secondly, manufacturers provide support and maintenance services to their customers. Given the complexity of roll forming machines, regular maintenance is essential to ensure their longevity and performance. Manufacturers often offer training programs for operators, enabling them to maximize the use of these machines and minimize downtimes.

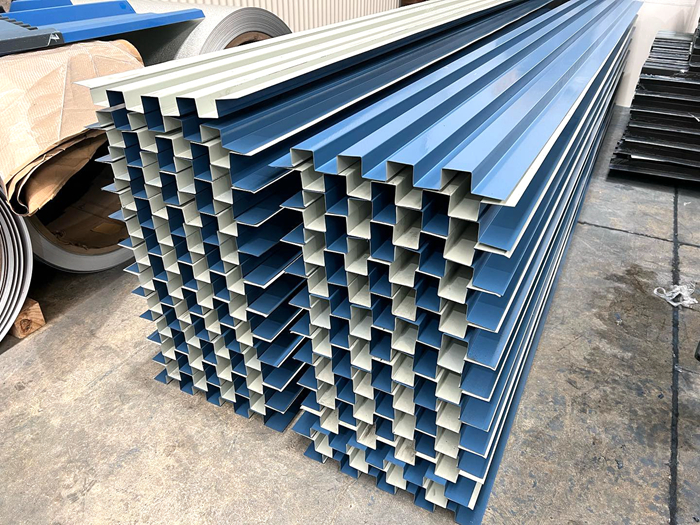

angle steel roll forming machine manufacturers

Additionally, manufacturers are crucial in promoting sustainability. Many are now focusing on producing machines that consume less energy and generate less waste, contributing to a more environmentally friendly manufacturing process. As the global emphasis on sustainable practices grows, companies that invest in energy-efficient machinery can significantly enhance their market competitiveness.

Selection Criteria for Reliable Manufacturers

When choosing an angle steel roll forming machine manufacturer, several factors should be considered. Quality is paramount; the machines should be robust and reliable to handle the demanding nature of metal forming processes. Potential buyers should look for manufacturers with a proven track record and positive reviews from existing customers.

Another critical aspect is the level of customization offered. Different projects may require specific designs and adjustments, so it is essential to work with manufacturers who are willing to understand and meet these unique needs.

Support and after-sales service are equally important. A manufacturer that provides comprehensive customer support ensures that any operational issues can be addressed promptly, minimizing interruptions in production.

Conclusion

The impact of angle steel roll forming machine manufacturers extends far beyond the machinery they produce. They are central to innovation, efficiency, and sustainability in the construction industry. As the demand for angle steel continues to grow, manufacturers must evolve and adapt, providing their clients with cutting-edge technology and unparalleled support. Investing in the right manufacturer not only leads to enhanced production capabilities but also contributes significantly to the overall success of construction projects worldwide. In a landscape of constant change, reliable partnerships with manufacturers can be a deciding factor in maintaining a competitive edge.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025