Feb . 10, 2025 19:38

Back to list

angle roll forming machine factories

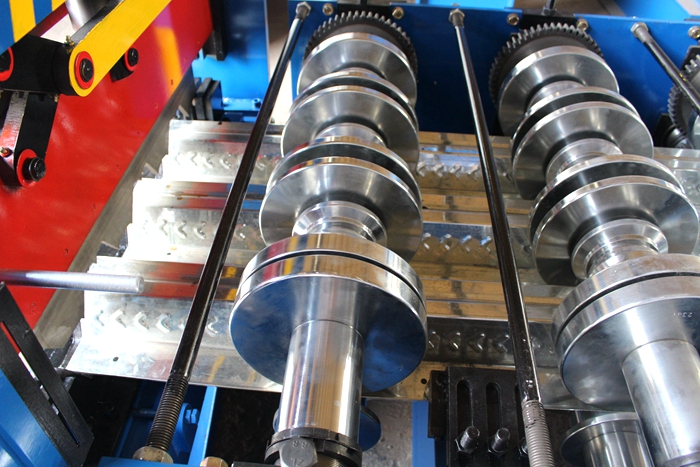

Angle roll forming machines are at the forefront of the metal forming industry, serving as indispensable tools for manufacturers looking to create precise and high-quality metal profiles. With the increase in demand for efficient and customizable metal components, factories specializing in angle roll forming machines are becoming pivotal within the sector. Through their innovative techniques and advanced machinery, these factories contribute a great deal to the engineering and construction industries by providing components that are not only durable but also customizable to client specifications.

Authoritativeness in angle roll forming machine factories is reflected in their collaborative projects with key industry players and participation in international trade shows and workshops. Engaging with global networks allows these factories to stay updated with technological advancements and industry trends. Partnerships with steel manufacturers and construction firms also embody their influential position in driving industry standards and innovations. Furthermore, trustworthiness is cemented by the transparent business practices these factories employ. Comprehensive customer support services, from the initial consultation phase to post-production follow-ups, ensure client confidence in their offerings. Clear communication, timely deliveries, and responsive after-sales support exemplify their commitment to customer satisfaction. In an industry where reliability is paramount, this facet of their operations cannot be undervalued. In conclusion, angle roll forming machine factories are pivotal in shaping the future of the metal forming industry. Their emphasis on technological advancement, stringent quality assurance measures, skilled expertise, and customer-centric approaches establish them as torchbearers in the field. These factories not only meet the high standards of quality and precision demanded by modern engineering but also drive forward the boundaries of what can be achieved with metal fabrication. For anyone involved in projects requiring precise and durable metal angles, working with a reputable angle roll forming machine factory is an investment in quality and innovation.

Authoritativeness in angle roll forming machine factories is reflected in their collaborative projects with key industry players and participation in international trade shows and workshops. Engaging with global networks allows these factories to stay updated with technological advancements and industry trends. Partnerships with steel manufacturers and construction firms also embody their influential position in driving industry standards and innovations. Furthermore, trustworthiness is cemented by the transparent business practices these factories employ. Comprehensive customer support services, from the initial consultation phase to post-production follow-ups, ensure client confidence in their offerings. Clear communication, timely deliveries, and responsive after-sales support exemplify their commitment to customer satisfaction. In an industry where reliability is paramount, this facet of their operations cannot be undervalued. In conclusion, angle roll forming machine factories are pivotal in shaping the future of the metal forming industry. Their emphasis on technological advancement, stringent quality assurance measures, skilled expertise, and customer-centric approaches establish them as torchbearers in the field. These factories not only meet the high standards of quality and precision demanded by modern engineering but also drive forward the boundaries of what can be achieved with metal fabrication. For anyone involved in projects requiring precise and durable metal angles, working with a reputable angle roll forming machine factory is an investment in quality and innovation.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products