angle iron roll forming machine factory

Angle Iron Roll Forming Machine Factory An Overview

In today’s industrial landscape, efficiency, precision, and flexibility are paramount. The angle iron roll forming machine factory is one such innovation that has significantly transformed the way angle iron is produced. This specialized machinery is designed to create angle iron profiles with exceptional accuracy, catering to various sectors such as construction, manufacturing, and engineering.

What is an Angle Iron Roll Forming Machine?

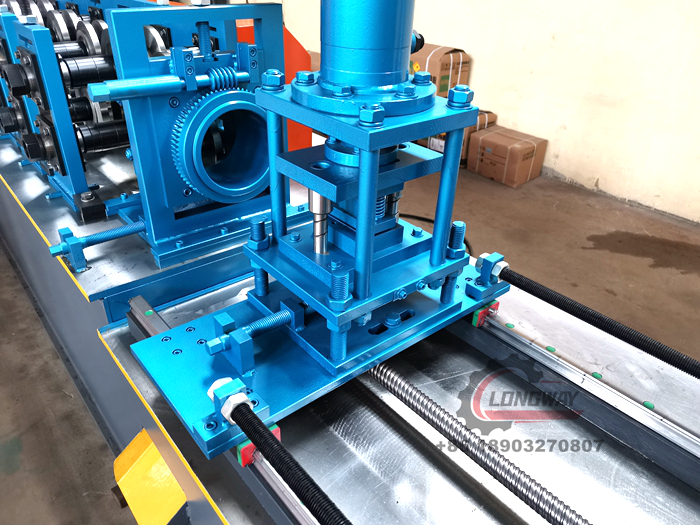

An angle iron roll forming machine is a type of equipment used to manufacture angle iron from flat metal sheets or coils. This machine operates by feeding the material through a series of rollers that gradually shape the metal into the desired angle. Typically, angle iron is characterized by its L-shaped cross-section, providing the mechanical properties required for a multitude of applications. The roll forming process is known for its efficiency, allowing for mass production with minimal waste.

The Manufacturing Process

The production of angle iron using a roll forming machine involves several steps. Initially, the raw material, typically hot or cold-rolled steel, is fed into the machine. The material is then passed through a series of rollers, each designed to progressively bend and shape the metal into an angle profile. The precision of this process is critical, as any misalignment can lead to defects in the final product.

Once the desired shape is achieved, the angle iron may undergo additional processes such as cutting, welding, or surface treatment, depending on its intended use. Ultimately, angle iron produced in this manner exhibits high strength, durability, and resistance to deformation, making it a popular choice in various construction and manufacturing applications.

Advantages of Using Angle Iron Roll Forming Machines

1. High Efficiency One of the most significant advantages of using roll forming machines is their ability to produce large quantities of angle iron at a rapid pace. This efficiency translates to reduced production time and lower labor costs, providing a competitive edge in today’s fast-moving market.

angle iron roll forming machine factory

2. Precision and Consistency Roll forming machines are designed to produce consistent profiles with minimal tolerances. This precision is crucial for applications where exact measurements are required, such as structural components in buildings and bridges. The automated nature of modern machines further enhances consistency across large production runs.

3. Versatility Angle iron roll forming machines can be customized to produce various profiles, widths, and thicknesses, adapting to the specific needs of different industries. This flexibility allows manufacturers to switch between products without the need for extensive reconfiguration, thereby streamlining operations.

4. Minimal Waste The roll forming process is inherently more efficient than traditional cutting methods. By utilizing continuous strips of metal, there is less waste material, making it an environmentally friendly option for sourcing raw materials.

The Role of Factories

Angle iron roll forming machine factories play a vital role in the supply chain. They are responsible not only for manufacturing the machines but also for ensuring they are maintained and serviced for optimal performance. Skilled technicians and engineers work to design innovative solutions that enhance production capabilities, incorporating the latest technology to meet the evolving needs of the industry.

These factories also focus on quality control, ensuring that each machine produced meets stringent international standards. By adhering to these guidelines, factories can guarantee the reliability and efficiency of their products, fostering trust among clients and contributing to the overall reputation of the manufacturing industry.

Conclusion

The angle iron roll forming machine factory is a cornerstone of modern metal production, offering countless benefits to manufacturers and industries that depend on precision-engineered components. The combination of high efficiency, versatility, and reduced waste makes it an appealing choice for companies looking to optimize their production processes. As technological advancements continue to shape the manufacturing landscape, angle iron roll forming machines will undoubtedly play a crucial role in meeting the demands of a rapidly evolving market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025