Angle Bar Rolling Machine Manufacturing Facility Overview and Capabilities

The Angle Bar Roll Forming Machine Factory A Pinnacle of Precision Engineering

The manufacturing industry has undergone significant transformations over the past few decades, with advancements in technology playing a crucial role in optimizing production processes. One such innovation that has gained popularity is the angle bar roll forming machine. These machines, essential for producing angle bars used in construction and various structural applications, have been meticulously engineered to ensure accuracy, efficiency, and high-quality output. In this article, we will explore the significance of angle bar roll forming machines, their manufacturing process in factories, and their impact on the industry.

Understanding Angle Bar Roll Forming

Angle bars, also known as angle sections or L-shaped sections, are structural elements that provide strength and support to various constructions. They come in a variety of sizes and materials, with steel and aluminum being the most common. The roll forming process involves gradually shaping the material as it passes through a series of rollers, which progressively forms the desired angle. This method offers several advantages over traditional fabrication techniques, including reduced material wastage, enhanced production efficiency, and consistent quality.

The Manufacturing Process

The production of angle bar roll forming machines takes place in specialized factories equipped with advanced technology and skilled labor. The process begins with the design phase, where engineers create detailed plans and specifications based on the machine's intended use. This stage emphasizes precision engineering, ensuring that every component meets the required tolerances and standards.

Once the designs are finalized, the manufacturing of machine components begins. Factories typically utilize high-grade raw materials such as steel to ensure durability and longevity. The raw materials undergo various processes, including cutting, bending, and welding, to create the individual parts of the machine.

After the component manufacturing is complete, assembly begins. This process requires a high level of expertise, as each part must be assembled with precision. The alignment of rollers, the main frame, and other components is critical to the machine's performance. Once assembled, the machine undergoes rigorous testing to ensure it meets quality standards and operates smoothly.

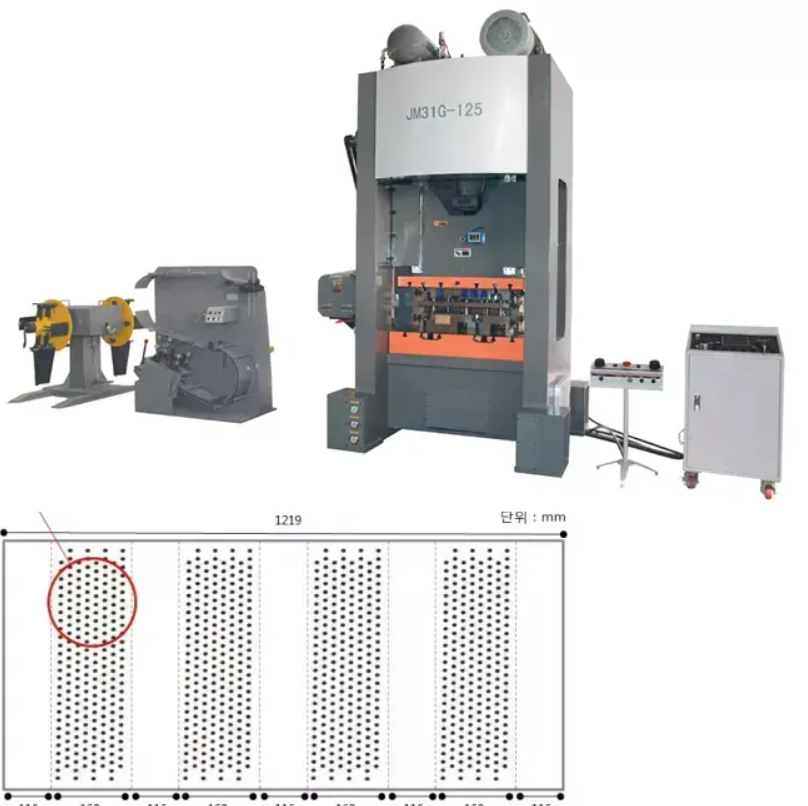

angle bar roll forming machine factory

Automation and Technology Integration

In recent years, automation and technology have revolutionized the angle bar roll forming industry. Modern machines are now equipped with advanced control systems that allow operators to easily set specifications and monitor production in real-time. This integration of technology enhances efficiency and reduces the potential for human error.

Moreover, the incorporation of computer numerical control (CNC) systems allows for greater precision in the shaping process. CNC technology enables machines to maintain consistent dimensions and tolerances throughout the production run, which is crucial for applications that require exact measurements.

The Impact on the Industry

The angle bar roll forming machine factory plays a vital role in the construction and manufacturing sectors. The demand for angle bars is continually rising, driven by urbanization and infrastructure development worldwide. As a result, factories producing angle bar roll forming machines are positioned to meet this growing demand, contributing to the industry’s growth and sustainability.

Furthermore, the efficient production capabilities of these machines help to lower costs for manufacturers. By minimizing material waste and increasing production speed, companies can offer competitive pricing while maintaining high standards of quality. This economic benefit extends to end-users, resulting in more affordable construction solutions and enhanced structural integrity.

Conclusion

The angle bar roll forming machine factory stands as a testament to precision engineering and technological advancement in the manufacturing sector. By combining innovative design, automation, and rigorous testing, these facilities play a crucial role in producing high-quality angle bars that meet the needs of modern construction. As the global demand for structural materials continues to grow, angle bar roll forming machines will undoubtedly remain at the forefront of efficient and sustainable manufacturing solutions, shaping the future of construction and infrastructure development.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025