aluminum roll forming machine factories

Aluminum Roll Forming Machine Factories An Overview of the Industry

In the rapidly evolving world of manufacturing, the demand for precision-engineered components continues to rise, particularly in industries where lightweight materials play a crucial role in enhancing efficiency and performance. Among these materials, aluminum stands out due to its exceptional strength-to-weight ratio, corrosion resistance, and versatility. This growing demand has led to the proliferation of aluminum roll forming machine factories around the globe, catering to various sectors including construction, automotive, aerospace, and furniture.

The Role of Aluminum Roll Forming Machines

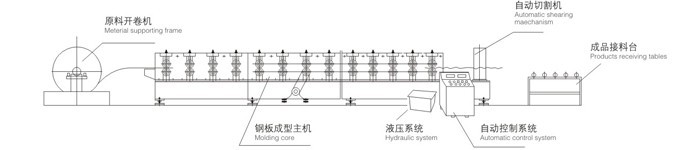

Aluminum roll forming machines are specialized equipment designed to produce continuous profiles from aluminum sheets. The roll forming process involves passing an aluminum sheet through a series of paired rollers, which gradually shape the material into the desired profile. This technique is particularly valued for its ability to create complex shapes with high precision and minimal waste.

Key Advantages of Aluminum Roll Forming

1. Efficiency and Speed The roll forming process is known for its high production speed and efficiency. Unlike other forming methods, it allows manufacturers to produce long lengths of a profile in a continuous manner, significantly reducing production times.

2. Material Utilization Roll forming minimizes scrap material, making it an economically viable option for manufacturers. The process can be optimized to ensure maximum utilization of the aluminum sheet, thus reducing overall material costs.

3. Consistency and Quality One of the standout features of aluminum roll forming is the ability to produce consistent and high-quality products. The controlled process ensures that the final profiles meet exact specifications, which is essential for applications where precision is non-negotiable.

4. Diverse Applications Products created using aluminum roll forming can be found in various industries. From construction components like roofing and wall panels to automotive parts such as chassis and frames, the versatility of aluminum makes it an attractive material for many manufacturers.

The Landscape of Aluminum Roll Forming Machine Factories

aluminum roll forming machine factories

The rise in demand for aluminum products has led to the establishment of numerous aluminum roll forming machine factories worldwide. These factories range from small, specialized operations to large-scale manufacturers capable of offering a wide array of machinery tailored to different industry needs.

Key Players in the Industry

Countries like China, Germany, and the United States have become key players in the aluminum roll forming machinery market. Chinese factories, in particular, are renowned for their ability to produce cost-effective machines without compromising quality. Meanwhile, European manufacturers often lead in innovation, providing advanced machinery equipped with the latest technology to improve efficiency and reduce downtime.

Innovation and Technological Advancements

As the industry matures, the focus on automation and technological advancements has increased. Modern aluminum roll forming machines are now equipped with sophisticated software that allows for precise control over the forming process. This technology enables manufacturers to quickly adapt to different product specifications and reduces the time required for setups between production runs.

Additionally, the integration of robots and automated systems in factories has further enhanced production capabilities. These innovations not only improve efficiency but also mitigate human error, leading to higher quality outputs.

Conclusion

The growth of aluminum roll forming machine factories reflects the broader trends in manufacturing, where efficiency, precision, and versatility are paramount. With continuous advancements in technology and an increasing focus on sustainability, the future looks promising for this sector. As industries continue to recognize the advantages of aluminum, the demand for roll forming machinery is expected to rise, driving innovation and competition within the market.

For businesses looking to invest in aluminum roll forming capabilities, understanding the landscape of manufacturers is essential. By aligning with reputable factories, companies can capitalize on the myriad benefits that aluminum roll forming offers, ensuring they remain competitive in a dynamic market. Whether it’s for high-volume production or specialized components, the role of aluminum roll forming machines in modern manufacturing cannot be overstated.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025