aluminum profile roll forming manufacturers

The Rise of Aluminum Profile Roll Forming Manufacturers

In the contemporary manufacturing landscape, the demand for lightweight and durable materials has significantly increased, leading to the prominence of aluminum profile roll forming. This process not only allows manufacturers to produce complex shapes with high precision but also optimizes material usage and enhances structural integrity. As a result, the number of aluminum profile roll forming manufacturers has surged, each vying to offer innovative solutions that meet diverse industry needs.

Understanding Aluminum Profile Roll Forming

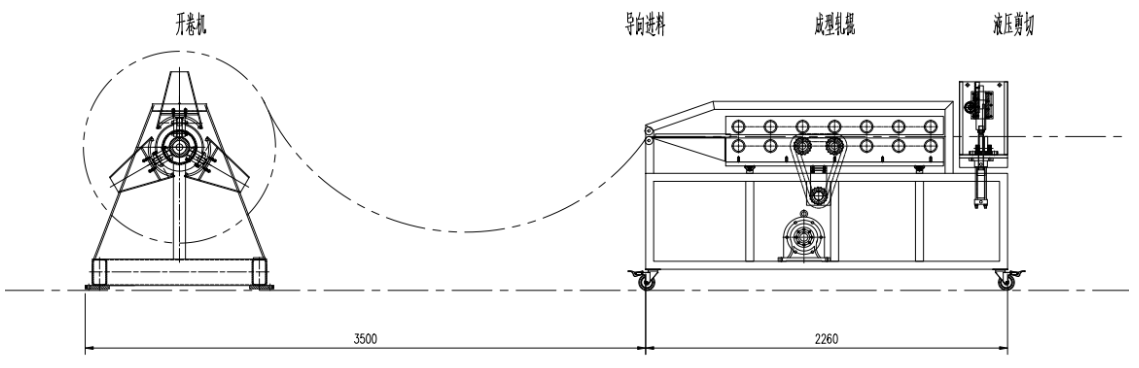

Aluminum profile roll forming is a manufacturing process that involves the continuous bending of aluminum sheets into various shapes. This is accomplished through a series of rollers, which incrementally shape the metal as it passes through the machines. The flexibility of this process means that manufacturers can create a wide range of profiles, including angles, channels, and custom shapes that cater to specific applications, from construction to automotive industries.

One of the primary advantages of aluminum as a material is its lightweight nature while maintaining excellent strength-to-weight ratios. This characteristic is particularly valuable in sectors where reducing the weight of components can lead to improved fuel efficiency and overall performance. Additionally, aluminum is resistant to corrosion, further extending the lifespan of products made from it. As a result, the role of aluminum profile roll forming manufacturers becomes increasingly critical in meeting both the economic and technical demands of modern industries.

Key Players in the Industry

The aluminum profile roll forming market features a diverse range of manufacturers, each with its own set of capabilities and specializations. Established companies often lead the way with advanced technology and extensive industry experience. These manufacturers invest significantly in research and development to innovate their production processes, incorporating automation and smart manufacturing techniques that increase efficiency and reduce waste.

Furthermore, many manufacturers focus on sustainability, utilizing recycled aluminum in their products. This not only minimizes environmental impact but also appeals to a growing customer base that values eco-friendly practices. By adopting such measures, aluminum profile roll forming manufacturers position themselves as leaders in a competitive market.

aluminum profile roll forming manufacturers

Applications Across Industries

Aluminum profiles produced through roll forming are utilized in a myriad of applications. In the construction industry, they are commonly used for window frames, doors, and facades due to their aesthetic appeal and durability. The automotive sector benefits from aluminum components that contribute to vehicle weight reduction, thereby enhancing fuel efficiency and reducing emissions. Additionally, industrial applications such as machinery frames and support structures leverage the strength and adaptability of aluminum profiles.

The versatility of aluminum also extends to the electronics industry, where heat sinks and housings are often produced using aluminum roll forming processes. This adaptability enables manufacturers to cater to a diverse clientele, providing customized solutions that meet specific performance requirements.

Future Trends in Aluminum Profile Roll Forming

As we move forward, the trend towards digitalization in manufacturing is becoming increasingly influential. Manufacturers are leveraging data analytics, IoT, and automation to optimize production processes. This digital transformation enhances quality control and reduces lead times, enabling faster turnarounds for customers.

Moreover, the demand for aluminum profiles is expected to grow due to heightened environmental regulations and the push for more sustainable materials. As electric vehicles gain popularity and green building practices become the norm, aluminum profile roll forming manufacturers will play a crucial role in supplying components that aid in these efforts.

Conclusion

In summary, aluminum profile roll forming manufacturers are at the forefront of an evolving industry that prioritizes efficiency, sustainability, and innovation. With the growing demand for lightweight and eco-friendly materials, these manufacturers are well-positioned to meet the challenges and opportunities of the future. By embracing technological advancements and adopting sustainable practices, they can continue to thrive in a competitive market while delivering high-quality products that benefit various sectors. As industries lean more towards innovative and environmentally conscious solutions, the role of aluminum profile roll forming manufacturers will be more critical than ever in shaping the future of manufacturing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025