aluminium roofing sheet making machine factories

The Rise of Aluminium Roofing Sheet Making Machines A Sustainable Solution for the Construction Industry

In recent years, the construction industry has witnessed an increasing demand for innovative and sustainable materials. Among these, aluminium stands out as a versatile and efficient choice, particularly in roofing applications. With the rapid growth of this sector, the importance of aluminium roofing sheet making machines cannot be overstated. These specialized machines are at the forefront of manufacturing high-quality roofing sheets that offer durability, aesthetics, and sustainability.

Aluminium roofing sheets are renowned for their lightweight properties, corrosion resistance, and longevity. Unlike traditional materials, aluminium does not rust, making it an ideal option for various climatic conditions. It can withstand harsh weather environments, which is why it has become a preferred choice for both residential and commercial buildings. As more architects and builders advocate for sustainable construction practices, the role of aluminium roofing is increasingly vital.

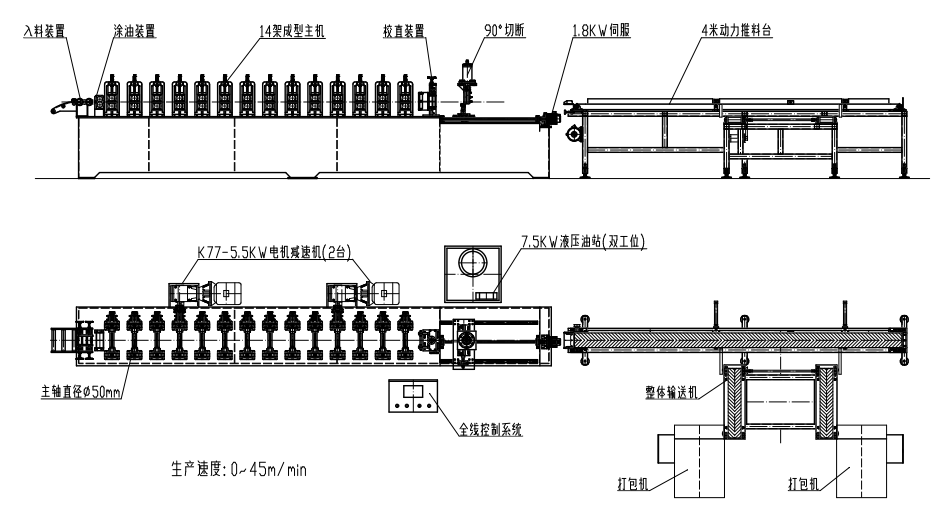

To meet the growing demand for aluminium roofing sheets, factories equipped with advanced aluminium roofing sheet making machines have emerged across the globe. These machines are designed to produce sheets in various thicknesses, sizes, and finishes, thereby catering to a wide range of customer needs. The manufacturing process typically involves the continuous casting of aluminium strips, which are then processed through a series of rollers to achieve the desired thickness and shape. Advanced technology ensures precision in every cut and fold, leading to a superior final product.

Furthermore, automation has played a significant role in transforming the efficiency of aluminium roofing sheet production. Modern machines are often equipped with computerized control systems that facilitate real-time monitoring and adjustment of the manufacturing parameters. This not only enhances the quality of the output but also minimizes waste, making the process more environmentally friendly. In addition, many factories now incorporate recycling processes, using scrap aluminium to produce new sheets, thus aligning with the principles of a circular economy.

aluminium roofing sheet making machine factories

The benefits of investing in aluminium roofing sheet making machines extend beyond production capabilities. Factories are increasingly recognizing the importance of energy efficiency. Many of these machines are designed to consume less energy, thereby reducing operational costs and the carbon footprint associated with manufacturing. Sustainable energy sources, such as solar and wind power, can be integrated into factory operations, further enhancing environmental sustainability.

Moreover, the growing urban population and the accompanying rise in infrastructure development are significant drivers for the aluminium roofing sheet market. As cities expand, the demand for buildings with energy-efficient roofs that can reflect heat and help regulate indoor temperatures increases. The properties of aluminium roofing sheets contribute to energy savings for buildings, making them an attractive option for environmentally conscious developers.

The global market for aluminium roofing materials is poised for further expansion, fueled by increasing regulations related to sustainability and energy efficiency. Builders and property developers are now more inclined to select materials that not only meet functional requirements but also offer aesthetic appeal and lower maintenance costs. Aluminium's versatility allows for a variety of designs and finishes, appealing to diverse architectural styles.

In conclusion, the importance of aluminium roofing sheet making machines cannot be underestimated in today's construction landscape. As more industries seek sustainable practices and materials, aluminium roofing stands out as a leading choice. The factories that produce these sheets are at the heart of innovation, integrating advanced technology and sustainable manufacturing practices. This evolving industry not only responds to market demand but also plays a crucial role in shaping a more sustainable future for construction and architecture, demonstrating how machinery, material, and environmental responsibility can work hand in hand. As we move forward, investing in these advanced machines will be essential to meet the challenges and opportunities that lie ahead in the construction industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025