Aluminium Roofing Sheet Production Line Manufacturers and Suppliers Worldwide

The Evolution of Aluminium Roofing Sheet Making Machines A Deep Dive

In the rapidly advancing world of construction materials, aluminium roofing sheets have emerged as a popular choice due to their durability, lightweight, and resistance to corrosion. This has led to an increase in demand for efficient manufacturing processes, leading to the evolution of aluminium roofing sheet making machines. These machines have become essential in factories worldwide, enabling the mass production of high-quality roofing sheets. This article explores the mechanics of these machines, the benefits of aluminium roofing sheets, and the future of manufacturing practices in this sector.

Understanding Aluminium Roofing Sheets

Aluminium roofing sheets are known for their longevity and ability to withstand harsh weather conditions. Unlike traditional materials such as steel, aluminium does not rust, making it an ideal choice for various environments. It is also lightweight, which simplifies transportation and installation. Furthermore, aluminium is a highly versatile material, allowing for several designs and finishes that can enhance the aesthetic appeal of a building.

The manufacturing process of these sheets typically involves melting aluminium and shaping it into thin sheets through processes such as rolling or extrusion. The efficiency and precision of these processes are largely dependent on the machinery used, making the selection of the right machine vital for producing quality products.

Manufacturing Process and Machinery

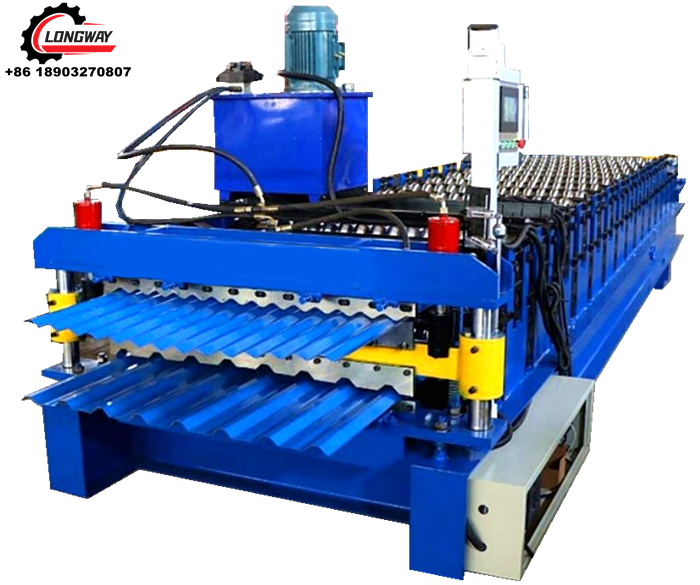

The aluminium roofing sheet making machine is typically composed of several key components, including a roll forming machine, cutting equipment, and a control system.

1. Roll Forming Machine This is the heart of the operation. The roll forming machine takes flat aluminium coils and passes them through various rollers to shape them into roofing sheets. The machine can be adjusted to create different profiles, catering to specific design requirements.

2. Cutting Equipment After forming, the sheets must be cut to the desired lengths. Advanced machines use computer numerical control (CNC) technology to ensure precise cuts, which minimizes waste and enhances the overall efficiency of the production process.

3. Control Systems Modern machines are equipped with sophisticated control systems that allow for automation and integration with other manufacturing processes. These systems enable operators to monitor production in real-time, ensuring the machine runs smoothly and adjustments can be made promptly.

Benefits of Investing in Aluminium Roofing Sheet Making Machines

Investing in aluminium roofing sheet making machines presents several benefits for manufacturers

aluminium roofing sheet making machine factories

1. Cost Efficiency Automated machinery reduces labor costs and minimizes material wastage. This efficiency translates into higher profit margins for manufacturers.

2. Quality Control Advanced machines produce uniform products with fewer defects, enhancing overall product quality. Consistency in production is crucial in maintaining customer satisfaction and brand reputation.

3. Flexibility Many modern machines can easily switch between different designs and specifications, allowing manufacturers to respond quickly to market trends and client demands.

4. Environmental Impact Aluminium is recyclable, and the manufacturing processes can be optimized for energy efficiency. Using advanced machinery can significantly reduce the carbon footprint of production.

Future Trends in Aluminium Roofing Sheet Manufacturing

As technology continues to evolve, several trends are expected to shape the future of aluminium roofing sheet manufacturing.

1. Increased Automation The trend towards automation will likely continue, with more factories adopting robotics and artificial intelligence to further optimize production lines.

2. Sustainability As global awareness of environmental issues increases, manufacturers will focus on sustainable practices. This includes using renewable energy sources and developing eco-friendly production methods.

3. Smart Manufacturing Integrating the Internet of Things (IoT) into manufacturing processes can lead to smarter factories where machines communicate, share data, and optimize production autonomously.

4. Customization With advancements in technology, customization of roofing sheets to meet specific client requests will become easier and faster, allowing manufacturers to differentiate themselves in a competitive market.

Conclusion

The aluminium roofing sheet making machine has revolutionized the construction materials industry, making the production of high-quality roofing sheets efficient and cost-effective. As manufacturers embrace technological advancements and sustainable practices, the future looks promising. The ongoing developments in machinery will not only enhance productivity but will also contribute to a greener industry, aligning production practices with the increasing demand for environmental responsibility.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025