Feb . 03, 2025 02:39

Back to list

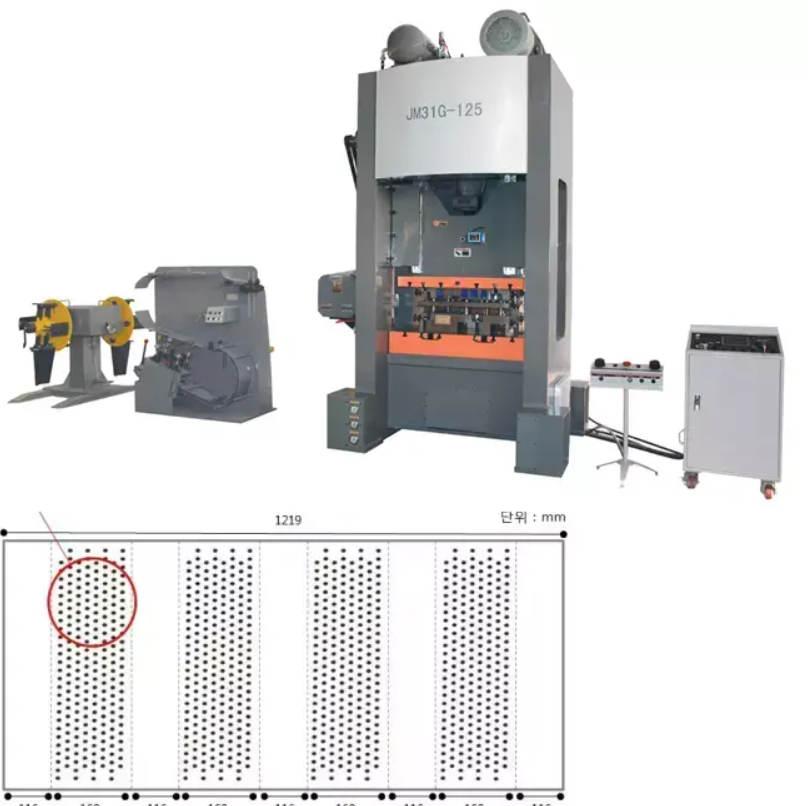

corrugated iron roofing sheet making machine

The evolution of the construction industry has seen a shift towards materials that offer durability, affordability, and sustainability. One such material is aluminium roofing, prized for its lightweight nature, resistance to corrosion, and recyclability. Central to meeting the growing demand for aluminium roofing is the aluminium roofing sheet making machine. In this article, we explore the intricacies of this machine, underscoring its importance, functionality, and the expertise required to optimize its performance.

Trustworthiness is the cornerstone of relations between manufacturers and stakeholders in the aluminium roofing industry. Machines that consistently deliver high-quality outputs fortify the reputation of manufacturers. Providing reliable, durable, and aesthetically pleasing roofing solutions engenders consumer confidence. Furthermore, transparency in manufacturing practices and the provenance of raw materials builds trust in the company's commitment to ethical and sustainable production. Sustainability is an increasingly important trend in manufacturing aluminium roofing sheets. Using machines that enable high recyclability of aluminium aligns with environmental priorities. Manufacturers that adopt these practices not only comply with regulatory demands but also appeal to an eco-conscious consumer base. This sustainable approach reinforces brand integrity and positions these companies as pioneers in responsible manufacturing. The future of aluminium roofing sheet making machines looks promising with ongoing technological advancements. Integration with IoT (Internet of Things) systems can lead to smarter machines that predict maintenance needs, optimize energy use, and streamline operations. This fusion of technology and manufacturing expertise promises to deliver increasingly sophisticated outcomes. In conclusion, the aluminium roofing sheet making machine is more than just a tool; it is a dynamic component of modern manufacturing that requires skilled operation, constant innovation, and commitment to quality. Companies leveraging this technology are setting standards in the roofing industry, offering products that meet the highest criteria of durability and design excellence. As the industry evolves, so will these machines, continuing to play a critical role in shaping environmentally friendly and structurally sound roofing solutions for the world.

Trustworthiness is the cornerstone of relations between manufacturers and stakeholders in the aluminium roofing industry. Machines that consistently deliver high-quality outputs fortify the reputation of manufacturers. Providing reliable, durable, and aesthetically pleasing roofing solutions engenders consumer confidence. Furthermore, transparency in manufacturing practices and the provenance of raw materials builds trust in the company's commitment to ethical and sustainable production. Sustainability is an increasingly important trend in manufacturing aluminium roofing sheets. Using machines that enable high recyclability of aluminium aligns with environmental priorities. Manufacturers that adopt these practices not only comply with regulatory demands but also appeal to an eco-conscious consumer base. This sustainable approach reinforces brand integrity and positions these companies as pioneers in responsible manufacturing. The future of aluminium roofing sheet making machines looks promising with ongoing technological advancements. Integration with IoT (Internet of Things) systems can lead to smarter machines that predict maintenance needs, optimize energy use, and streamline operations. This fusion of technology and manufacturing expertise promises to deliver increasingly sophisticated outcomes. In conclusion, the aluminium roofing sheet making machine is more than just a tool; it is a dynamic component of modern manufacturing that requires skilled operation, constant innovation, and commitment to quality. Companies leveraging this technology are setting standards in the roofing industry, offering products that meet the highest criteria of durability and design excellence. As the industry evolves, so will these machines, continuing to play a critical role in shaping environmentally friendly and structurally sound roofing solutions for the world.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products