High-Quality Aluminium Roll Forming Machine Manufacturer | Precision Engineering Solutions

Aluminium Roll Forming Machine Factory Revolutionizing the Manufacturing Process

In today’s competitive manufacturing landscape, the demand for efficient and precise production methods is at an all-time high. Among the various manufacturing technologies, aluminium roll forming stands out as a versatile and cost-effective solution. Aluminium roll forming machine factories play a pivotal role in the production of aluminium products, catering to a diverse range of industries from construction to automotive.

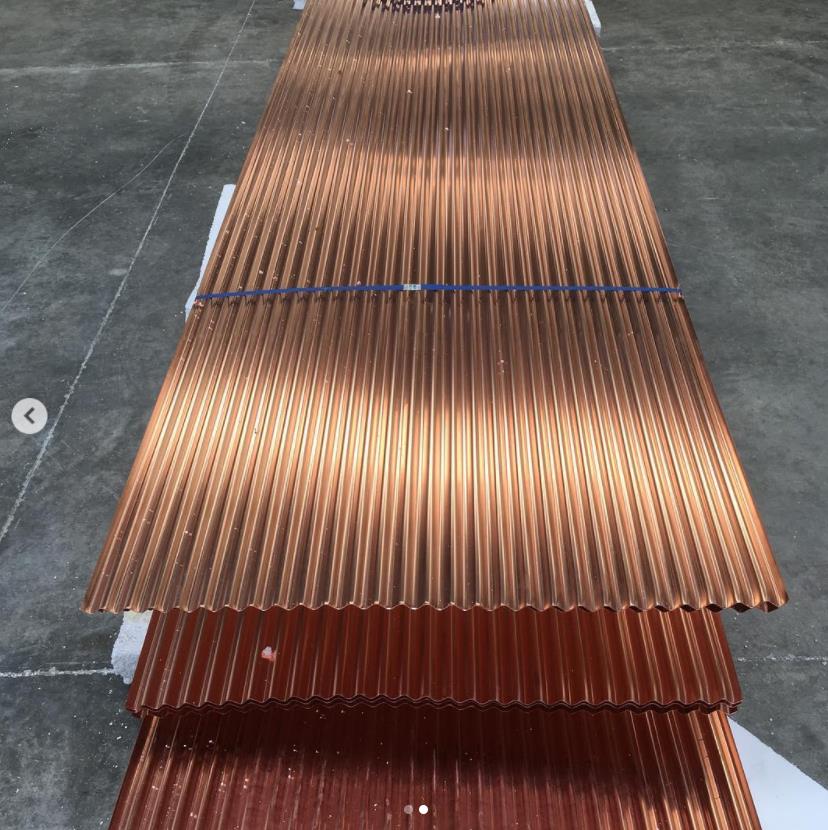

Aluminium roll forming is a continuous bending operation where a long strip of aluminium is passed through a series of rolls to create specific shapes and profiles

. The process allows for the creation of complex geometries with high precision and consistency, making it an ideal choice for producing components such as roofing sheets, wall panels, and structural frames.At the heart of this process is the aluminium roll forming machine, a sophisticated piece of equipment designed for high-speed production with minimal waste. These machines are equipped with advanced technology, including computer numerical control (CNC) systems that ensure accurate and repeatable production. By automating various aspects of the manufacturing process, including cutting and bending, these machines significantly reduce labor costs and enhance productivity.

aluminium roll forming machine factory

Aluminium roll forming machine factories are dedicated to not only manufacturing these machines but also customizing them to meet the specific needs of their clients. Each project begins with a thorough analysis of the client’s requirements, including the desired profile, material thickness, and production volume. This ensures that the machines produced are tailored to deliver optimal performance, maximizing efficiency while minimizing downtime.

Moreover, environmental considerations are becoming increasingly important in manufacturing. Aluminium is known for its recyclability, and the roll forming process generates minimal waste compared to traditional metalworking techniques. Factories are also adopting sustainable practices, such as energy-efficient machinery and recycling scrap material, further enhancing their eco-friendly credentials.

Quality assurance is another critical aspect of operations within aluminium roll forming machine factories. Rigorous testing protocols are implemented at every stage of production, ensuring that each machine meets stringent quality standards before delivery. This commitment to quality not only boosts customer confidence but also fosters long-term relationships with clients.

In conclusion, aluminium roll forming machine factories are at the forefront of modern manufacturing, providing essential machinery that supports the production of high-quality aluminium products. Their role in advancing technology, maintaining quality, and promoting sustainability cannot be overstated. As industries continue to evolve and adapt to changing market demands, the significance of these factories will only grow, ensuring that they remain integral to the manufacturing sector’s success in the years to come.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025