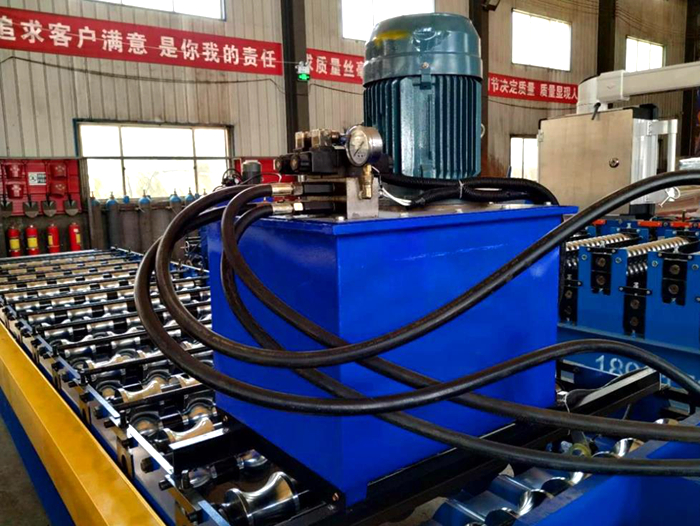

ag panel roll forming machine factory

The Role of AG Panel Roll Forming Machines in Modern Construction

In the ever-evolving landscape of construction and manufacturing, the AG panel roll forming machine has emerged as a pivotal technology. This innovative equipment is specifically designed to produce high-quality metal panels used for roofing, walls, and other structural applications. Understanding the functionalities and benefits of these machines can provide insights into their critical role in the construction industry.

AG panel roll forming machines operate on a simple yet effective principle. They take flat metal sheets, usually made from steel or aluminum, and shape them into specific profiles through a series of rollers. This process ensures that the panels produced are uniform, durable, and tailored to meet specific design requirements. The versatility of AG panel roll forming machines allows them to create various panel shapes and sizes, catering to diverse architectural needs.

The Role of AG Panel Roll Forming Machines in Modern Construction

Moreover, AG panel roll forming machines are known for their ability to produce high-strength panels. The cold-forming process employed by these machines enhances the structural integrity of the metal panels, making them resistant to deformation under pressure. This quality is crucial in construction, especially in regions prone to extreme weather conditions. The resulting panels are capable of withstanding heavy snowfall, torrential rain, and strong winds, providing long-lasting protection for buildings.

ag panel roll forming machine factory

Another significant benefit of AG panel roll forming machines is their customization capabilities. With advancements in technology, manufacturers can easily modify the design and specifications of the panels to meet specific project requirements. Whether it’s a unique profile, specific colors, or additional features like insulation, the flexibility of these machines allows for a tailored approach to construction. This level of customization enables architects and builders to experiment with design aesthetics while ensuring functional efficiency.

In addition to efficiency and customization, AG panel roll forming machines also contribute to cost savings in the long run. By streamlining the production process and reducing material waste, these machines help lower the overall costs associated with building projects. Furthermore, the durability of the panels translates to reduced maintenance costs over time, making them a wise investment for contractors and developers.

As the construction industry continues to embrace technological advancements, the importance of AG panel roll forming machines cannot be overstated. These machines facilitate a quicker, more efficient, and cost-effective way to create essential building materials. Their ability to produce high-quality, customizable panels positions them as a fundamental resource in modern construction, responding to the growing demand for sustainable and innovative building solutions.

In conclusion, the role of AG panel roll forming machines in modern construction is multifaceted. They not only enhance production efficiency and reduce waste but also provide construction professionals with the flexibility to create customized solutions. With their strength, durability, and cost-effectiveness, AG panel roll forming machines are set to play a crucial role in shaping the future of the construction industry. As we move towards more sustainable and efficient building practices, the significance of this technology will undoubtedly continue to grow.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025