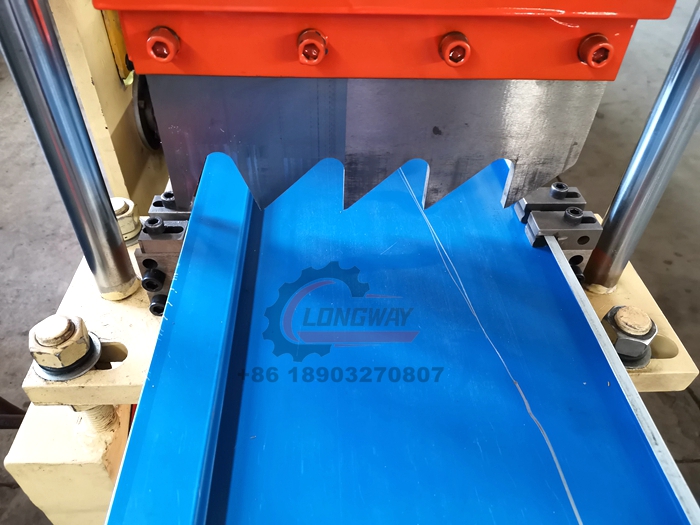

ag panel roll forming machine

AG Panel Roll Forming Machine Revolutionizing the Construction Industry

In recent years, the construction industry has witnessed significant advancements in technology, particularly with the introduction of innovative machinery designed to enhance efficiency and precision. One such innovation is the AG panel roll forming machine, which has become an essential tool for producing high-quality metal panels for roofing and wall applications. This article explores the features, benefits, and applications of AG panel roll forming machines, showcasing how they are transforming the way we build.

What is an AG Panel Roll Forming Machine?

An AG panel roll forming machine is a specialized piece of equipment designed to produce Ag panels—also known as agricultural panels or architectural panels—made from metals like steel and aluminum. These machines use a continuous process that involves feeding a flat metal sheet through a series of rollers that gradually shape the material into the desired profile. The process not only ensures consistency in design but also significantly reduces production time compared to traditional manufacturing methods.

Features of AG Panel Roll Forming Machines

1. Precision Engineering AG panel roll forming machines are engineered to deliver high precision in panel dimensions and profiles. Advanced computer numerical control (CNC) technology allows for intricate designs and consistency, reducing waste and ensuring high-quality end products.

2. Versatility These machines can accommodate various metal thicknesses and widths, allowing manufacturers to produce different panel types for a wide range of applications. Whether for agricultural buildings, industrial structures, or residential roofing, AG panel roll forming machines cater to diverse needs.

3. Automated Production With automation features, these machines require minimal manual intervention. They are often equipped with sensors to monitor the production process, ensuring smooth operation and reducing the risk of errors. This automation not only enhances efficiency but also lowers labor costs.

4. Durability and Reliability Built with robust materials and advanced engineering, AG panel roll forming machines are designed to withstand rigorous operational demands. Their reliability translates to longer production runs and less downtime, vital for meeting tight construction deadlines.

ag panel roll forming machine

Benefits of Using AG Panel Roll Forming Machines

1. Cost-Effectiveness By reducing material waste and labor costs while increasing production speed, AG panel roll forming machines provide a cost-effective solution for manufacturers. The ability to produce panels on-site also minimizes transportation expenses.

2. Quality Assurance The precision and consistency of the panels produced enhance the overall quality of construction projects. High-quality panels contribute to better performance, durability, and aesthetics of buildings.

3. Sustainability Modern roll forming machines are designed with sustainability in mind. They can efficiently utilize recycled metals and minimize energy consumption during the production process, aligning with the growing trend towards environmentally conscious construction practices.

Applications of AG Panel Roll Forming Machines

AG panel roll forming machines are widely used in various sectors, including agriculture, commercial construction, and residential building. They are ideal for producing roofing sheets, siding panels, and other structural components. The versatility of these machines allows builders to customize designs according to specific project requirements, enhancing their utility in different environments.

Conclusion

The AG panel roll forming machine represents a significant advancement in the manufacturing of metal panels. By combining precision, efficiency, and versatility, these machines are not only improving the quality of construction projects but also promoting sustainable practices within the industry. As the demand for reliable and aesthetically pleasing building materials continues to grow, the role of AG panel roll forming machines will undoubtedly become increasingly vital in shaping the future of construction.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025