ag panel roll forming machine

Understanding AG Panel Roll Forming Machines

In the realm of modern manufacturing, the demand for efficient and high-quality production processes has significantly increased. One notable innovation in this sector is the AG panel roll forming machine. This cutting-edge technology is specifically designed to produce AG (agricultural) panels, which are widely utilized in various construction and agricultural applications.

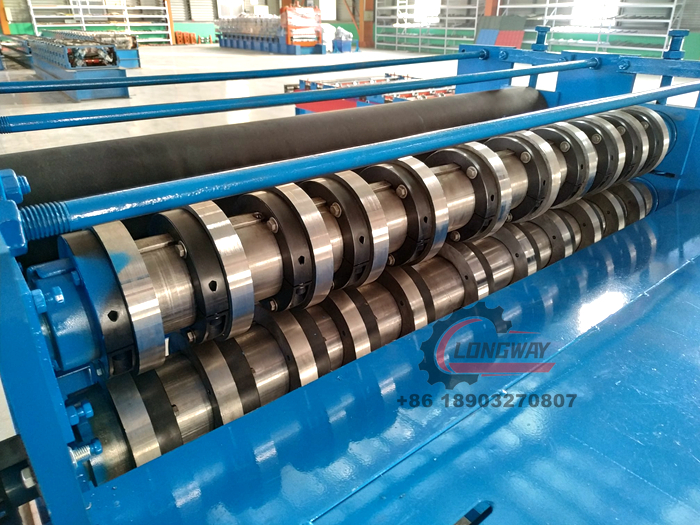

AG panel roll forming machines operate through a process called roll forming. This technique involves feeding metal sheets through a series of rollers that shape the material into the desired profile. The machine's design allows for continuous production, making it ideal for high-volume manufacturing. The rollers are precisely aligned to create panels that exhibit uniform thickness and consistency, ensuring that the end product meets the required specifications.

Understanding AG Panel Roll Forming Machines

Another benefit is the efficiency of the process. AG panel roll forming machines can operate at high speeds, drastically reducing production time compared to traditional forming methods. This increased efficiency translates to lower labor costs and higher output, allowing manufacturers to meet demand swiftly. Moreover, the automated nature of these machines reduces the likelihood of human error, further enhancing product quality.

ag panel roll forming machine

In addition to speed and efficiency, AG panels produced by roll forming machines are known for their durability and reliability. The materials used, typically high-strength steel or aluminum, provide excellent resistance to environmental factors such as corrosion, making them ideal for agricultural settings and industrial buildings. The precision of the roll forming process also means that the panels fit together seamlessly, minimizing the risk of leaks or structural weaknesses.

Environmental considerations are also a significant factor in the manufacturing process. Many AG panel roll forming machines are designed to be energy-efficient, reducing overall energy consumption during production. Additionally, these machines can work with recycled materials, contributing to sustainability in manufacturing practices.

The market for AG panel roll forming machines continues to grow, driven by advancements in technology and increasing demand for efficient production solutions. As agricultural and construction industries expand, the need for high-quality, reliable panels has never been more critical. Investing in state-of-the-art roll forming machines not only enhances production capabilities but also positions manufacturers to better serve their markets.

In conclusion, AG panel roll forming machines are at the forefront of modern manufacturing technology, offering numerous advantages such as efficiency, flexibility, and product quality. As industries continue to evolve, these machines will play a crucial role in meeting the needs of a dynamic and growing market. Whether for agricultural buildings or industrial applications, the importance of reliable AG panels produced by advanced roll forming technology cannot be overstated.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025