Jan . 22, 2025 00:53

Back to list

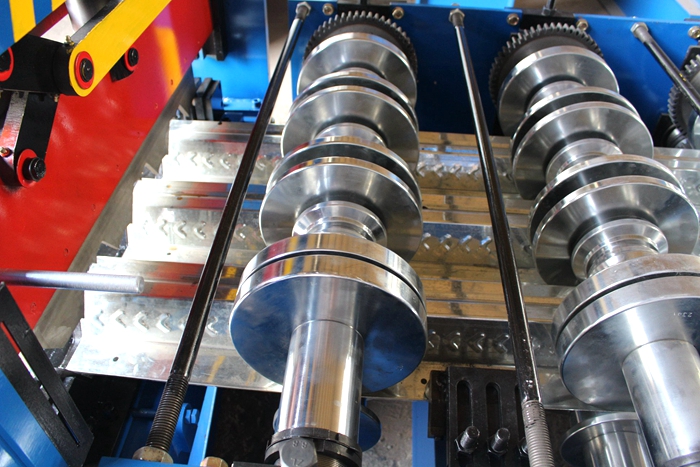

ag panel roll former

In the world of construction and manufacturing, the role of the ag panel roll former is indispensable. This innovative machine is designed to streamline the process of forming metal panels that are predominantly used in agricultural buildings and various construction projects. With its renowned efficiency and precision, the ag panel roll former has become a cornerstone in the industry, attracting attention from experts and authorities alike due to its exceptional capabilities and trustworthiness.

The versatility of the ag panel roll former is another selling point that cannot be overlooked. It adeptly handles a range of metal types and thicknesses, making it suitable for diverse applications beyond agricultural contexts. From industrial warehouses to residential construction, its adaptability renders it a valuable tool for a broad spectrum of projects. This flexibility, coupled with its precision engineering, means that the ag panel roll former can effortlessly switch between different profiles and projects, guaranteeing consistent quality regardless of specific requirements. Peer insights and authoritative reviews highlight the superior craftsmanship and innovation that underpins these machines. Experts frequently commend the seamless integration of automation and customization, aspects that distinctly benefit large-scale operations needing tailored solutions. Such accolades are not without substance; case studies reveal how businesses leveraging the ag panel roll former witness not just operational efficiency but also a marked increase in client satisfaction due to the consistently high quality of the finished products. Furthermore, the ecological footprint of the ag panel roll former is remarkably modest. By optimizing material usage and minimizing waste, these machines align with sustainable manufacturing practices. This commitment to environmental responsibility resonates with modern businesses striving to meet green standards and contribute positively to environmental conservation efforts. In conclusion, the ag panel roll former is not merely a machine; it is a vital asset to any metalworking and construction endeavor. Its celebrated efficiency, authoritative presence in the industry, and comprehensive support systems make it a beacon of experience, expertise, and trustworthiness. For any enterprise aiming to excel in precision panel fabrication while optimizing resources and maintaining quality, the ag panel roll former stands unrivaled as a strategic investment.

The versatility of the ag panel roll former is another selling point that cannot be overlooked. It adeptly handles a range of metal types and thicknesses, making it suitable for diverse applications beyond agricultural contexts. From industrial warehouses to residential construction, its adaptability renders it a valuable tool for a broad spectrum of projects. This flexibility, coupled with its precision engineering, means that the ag panel roll former can effortlessly switch between different profiles and projects, guaranteeing consistent quality regardless of specific requirements. Peer insights and authoritative reviews highlight the superior craftsmanship and innovation that underpins these machines. Experts frequently commend the seamless integration of automation and customization, aspects that distinctly benefit large-scale operations needing tailored solutions. Such accolades are not without substance; case studies reveal how businesses leveraging the ag panel roll former witness not just operational efficiency but also a marked increase in client satisfaction due to the consistently high quality of the finished products. Furthermore, the ecological footprint of the ag panel roll former is remarkably modest. By optimizing material usage and minimizing waste, these machines align with sustainable manufacturing practices. This commitment to environmental responsibility resonates with modern businesses striving to meet green standards and contribute positively to environmental conservation efforts. In conclusion, the ag panel roll former is not merely a machine; it is a vital asset to any metalworking and construction endeavor. Its celebrated efficiency, authoritative presence in the industry, and comprehensive support systems make it a beacon of experience, expertise, and trustworthiness. For any enterprise aiming to excel in precision panel fabrication while optimizing resources and maintaining quality, the ag panel roll former stands unrivaled as a strategic investment.

Latest news

Related Products