Africa 686 IBR Roof Sheet Making Machine - Cangzhou Longway|High Capacity&Custom Design

Product Overview

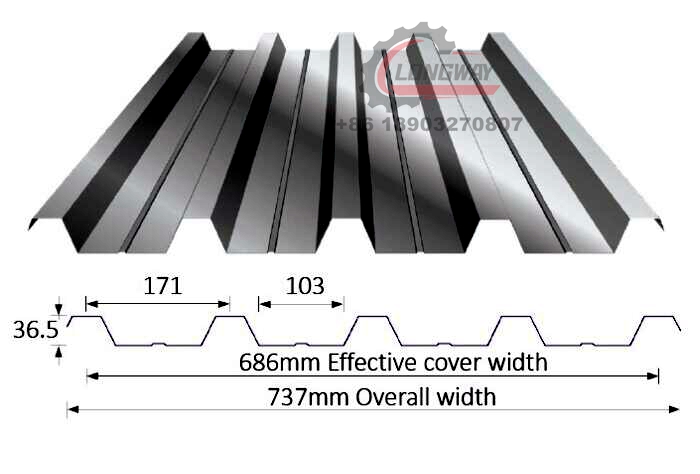

The Africa 686 IBR Roof Sheet Making Machine is a state-of-the-art roll forming system engineered to produce trapezoidal ribbed roofing sheets with a thickness range of 0.3mm to 0.8mm. This machine is particularly popular in the African market due to its high production capacity, cost-effectiveness, and adaptability to custom designs. The IBR profile is known for its superior strength-to-weight ratio, making it an ideal choice for residential, industrial, and commercial roofing projects.

One of the standout features of this machine is its customizable design capability, allowing manufacturers to produce wide-span roofing sheets, self-locking panels, and other specialized profiles. Whether you're looking for standard IBR profiles or unique architectural designs, the Africa 686 ensures flexibility and precision.

Technical Specifications

The Africa 686 IBR Roof Sheet Making Machine is equipped with high-grade materials and advanced engineering to ensure durability and efficiency. Below is a detailed specification table:

| Parameter | Details |

|---|---|

| Material Thickness Range | 0.3mm - 0.8mm (29-22 Gauge) |

| Raw Material | PPGI, PPGL, GI (Pre-painted Galvanized Steel) |

| Sheet Width | 914mm / 925mm |

| Power Requirement | 380V / 3-phase / 50Hz (Customizable) |

| Main Motor Power | 4kW + 4kW |

| Cutter Power | 4kW |

| Forming Speed | 15-20m/min |

| Machine Frame | 350mm H Beam Structure |

| Forming Shaft | 75mm Solid Shaft with Heat Treatment |

| Roller Material | High-Grade 45# Forged Steel |

| Forming Stations | 14-18 Rows |

| Transmission Type | Chain Drive (1-inch Double Chain) |

| Cutting Type | Hydraulic Pillar Type with Length-Set Cutting |

| Control System | PLC Delta + Inverter Delta |

| Touch Screen | Standard |

| Machine Dimensions | 7.5m × 1.5m × 1.2m |

| Total Weight | Approx. 4.6T |

Key Features and Advantages

The Africa 686 IBR Roof Sheet Making Machine offers a range of advantages that make it a top choice for manufacturers:

- High Production Capacity: With a forming speed of 15-20m/min, this machine ensures efficient and continuous production to meet large-scale demands.

- Custom Design Flexibility: The machine supports custom profiles such as wide-span roofing sheets, self-locking panels, and specialized trapezoidal designs, catering to diverse market needs.

- Material Efficiency: The IBR profile is designed for maximum strength-to-weight ratio, reducing material waste and enhancing cost-effectiveness.

- Durability and Precision: Constructed with high-grade 45# forged steel rollers and a 350mm H-beam frame, the machine ensures long-term reliability and precision.

- User-Friendly Control System: Equipped with a PLC Delta control system and touchscreen interface, operators can easily monitor and adjust parameters for optimal performance.

Applications and Industry Use Cases

The Africa 686 IBR Roof Sheet Making Machine is versatile and suitable for a wide range of industrial and commercial applications, including:

- Residential Roofing: Ideal for single-family homes and multi-family units, the machine produces durable and aesthetically pleasing IBR sheets that withstand harsh weather conditions.

- Industrial Facilities: Used in warehouses, factories, and agricultural buildings, the machine's high production capacity ensures efficient manufacturing of large-scale roofing systems.

- Commercial Projects: Suitable for shopping centers, airports, and office complexes, the machine's custom design capabilities allow for unique architectural finishes.

- Infrastructure Development: The machine is also employed in bridge construction, highway overpasses, and public infrastructure projects where high-strength roofing materials are required.

For more information on the applications of IBR roofing sheets, visit the [Cangzhou Longway International Trade Co., Ltd. website](https://www.lwrollformingmachine.com/).

Company Background: Cangzhou Longway International Trade Co., Ltd.

Cangzhou Longway International Trade Co., Ltd. is a leading manufacturer and exporter of metal roll forming machinery, specializing in roof and wall panel machines. With a strong focus on innovation, quality, and customer satisfaction, the company has established itself as a trusted partner for global clients in the construction and manufacturing industries.

Based in Cangzhou, China, the company offers OEM and ODM services, allowing clients to customize machinery to their specific requirements. Their product portfolio includes IBR roof sheet machines, corrugated roofing sheet machines, and standing seam roof panel machines, among others.

Cangzhou Longway has successfully supplied machinery to clients in Africa, South America, Southeast Asia, and the Middle East, including Chile, Iran, the Philippines, and South Africa. Their commitment to excellence and customer-centric solutions has earned them a reputation for reliability and innovation.

For more details about the company, visit the [Cangzhou Longway International Trade Co., Ltd. website](https://www.lwrollformingmachine.com/).

Why Choose the Africa 686 IBR Roof Sheet Making Machine?

The Africa 686 IBR Roof Sheet Making Machine stands out in the market due to its combination of advanced technology, durability, and cost-effectiveness. Here are some key reasons to choose this machine:

- Superior Precision: The separate rolling design minimizes internal stress in the sheets, ensuring high-precision and consistent quality.

- Energy Efficiency: The hydraulic cutting system and chain drive mechanism reduce energy consumption, making the machine eco-friendly and cost-effective.

- Easy Maintenance: The machine's modular design allows for quick and hassle-free maintenance, minimizing downtime and maximizing productivity.

- Global Support: With OEM and ODM services, the company provides tailored solutions to meet the unique needs of clients worldwide.

For a detailed analysis of roll forming technology standards, refer to the [National Institute of Standards and Technology (NIST)](https://www.nist.gov/), which emphasizes the importance of precision manufacturing and material efficiency in industrial applications.

Conclusion

The Africa 686 IBR Roof Sheet Making Machine from Cangzhou Longway International Trade Co., Ltd. is a high-performance, versatile, and reliable solution for producing IBR roofing sheets. With its advanced technical specifications, customization options, and proven performance, this machine is an excellent investment for manufacturers looking to enhance productivity and meet global market demands.

Whether you're in the residential, industrial, or commercial sector, the Africa 686 offers the precision, durability, and efficiency needed to deliver high-quality roofing solutions. Contact Cangzhou Longway International Trade Co., Ltd. today to learn more about how this machine can transform your manufacturing process.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025