Affordable Shutter Strip Production Equipment for Efficient and Cost-Effective Manufacturing Solutions

The Rise of Cheap Shutter Strip Making Machines A Revolution in Manufacturing

In recent years, the demand for cost-effective manufacturing solutions has surged, particularly in the construction and home improvement industries. Among the innovations leading this charge is the cheap shutter strip making machine. This machine has revolutionized the way shutter strips are produced, offering a combination of efficiency, affordability, and accessibility that is hard to match.

Shutter strips, often used for windows and doors, serve as protective barriers against various elements, enhancing security and insulation. Traditionally, the production of these strips required significant investments in machinery, skilled labor, and time. However, with the advent of cheap shutter strip making machines, the landscape of manufacturing is changing dramatically.

One of the primary advantages of these machines is their affordability. Many small to medium-sized businesses, which previously could not afford high-end manufacturing equipment, can now invest in these cost-effective solutions. With prices significantly lower than traditional machinery, entrepreneurs can start their own production lines without breaking the bank. This accessibility not only boosts individual businesses but also stimulates local economies by creating jobs and fostering innovation.

Moreover, the efficiency of these machines is noteworthy. Modern technology has enabled manufacturers to produce shutter strips with speed and precision. Automated features allow for continuous production, reducing labor costs and minimizing human errors. This high level of automation means that companies can scale their output to meet growing demands without compromising on quality. The shorter production times lead to faster delivery schedules, which is a critical factor in today’s fast-paced market.

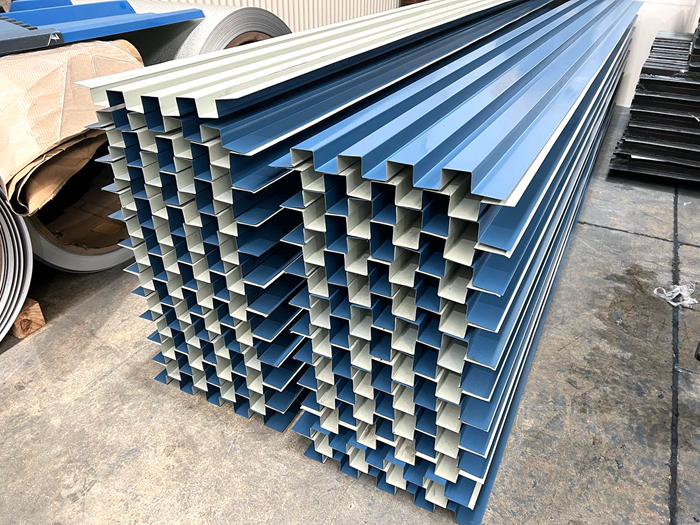

cheap shutter strip making machine

The versatility of cheap shutter strip making machines is another reason for their growing popularity. These machines can often handle a variety of materials, including wood, PVC, and aluminum, giving manufacturers the flexibility to cater to diverse customer needs. This adaptability allows businesses to tap into different segments of the market, enhancing their competitive edge.

In addition, the ease of operation of these machines makes them attractive even for those with little technical knowledge. Many models are designed with user-friendly interfaces, enabling operators to set up and manage production with minimal training. This characteristic is particularly appealing for startups and small businesses that may lack skilled technicians.

Sustainability is also a critical consideration in today’s manufacturing ecosystem. Many cheap shutter strip making machines are designed with energy-efficient technologies, reducing both energy consumption and waste. This aligns with the increasing demand for eco-friendly practices in manufacturing. By opting for these machines, businesses not only cut costs but also contribute to a greener economy.

However, it is essential to choose machines from reputable manufacturers. While cost is a significant factor, quality should not be overlooked. Investing in a machine that is built to last will save businesses from frequent repairs and replacements, ultimately leading to more significant savings in the long run.

In conclusion, the rise of cheap shutter strip making machines represents a significant shift in the manufacturing landscape. By providing affordable, efficient, and versatile solutions, these machines empower small businesses to thrive in a competitive market. As technology continues to advance, it is likely that we will see even more innovations in this field, further solidifying the importance of these machines in the future of manufacturing. For entrepreneurs looking to make their mark in the industry, now is the time to embrace this revolution and explore the potential it holds.