Affordable Prices for Factory-Made Rolling Shutter Making Machines with High Quality and Efficiency

Understanding the Price Factors of Rolling Shutter Making Machines

Rolling shutter making machines have garnered significant attention in the construction and manufacturing industries, primarily due to their essential role in producing high-demand rolling shutters for security and aesthetic purposes. As businesses seek a reliable solution for creating these products, understanding the pricing dynamics of rolling shutter making machines becomes crucial for making informed purchasing decisions.

Types of Rolling Shutter Making Machines

Before diving into pricing, it’s essential to comprehend the different types of rolling shutter making machines available in the market. Generally, machines can be categorized based on their operational mechanisms—manual, semi-automatic, and fully automatic machines. Manual machines are straightforward and cost-effective, making them suitable for small-scale production. In contrast, semi-automatic and fully automatic machines, while more expensive, offer higher efficiency and reduced labor costs, making them ideal for large manufacturers.

Factors Influencing the Price

1. Machine Specifications The cost of rolling shutter making machines often varies based on their specifications. Higher-quality machines that offer advanced features—such as better speed, precision, and durability—naturally come with a higher price tag. For instance, machines equipped with high-performance motors or advanced control systems tend to be more expensive because they can produce shutters at a faster rate and with greater accuracy.

2. Production Capacity The production capacity of the machine is another significant factor in determining the price. Machines designed for high-volume production typically exhibit a higher price due to their robust build and the technology used to facilitate mass production. Companies must assess their production needs and select a machine that can meet those demands without incurring unnecessary costs.

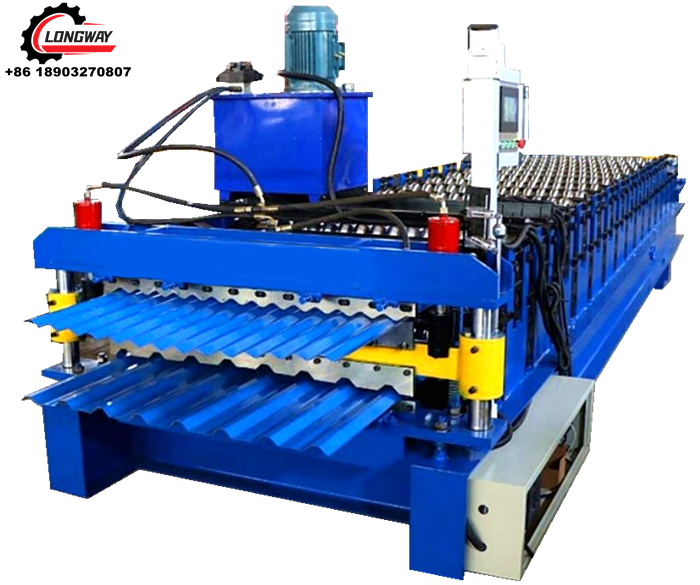

rolling shutter making machine price factory

3. Material Compatibility The type of materials that a machine can handle also plays a crucial role in its pricing. Machines that can work with a wider variety of materials, such as aluminum, steel, or PVC, will generally cost more. This versatility allows manufacturers to cater to diverse customer preferences and applications, ultimately enhancing their market competitiveness.

4. Brand and Manufacturer Like many products, the brand reputation and manufacturer also impact the pricing. Well-established manufacturers with a history of producing high-quality machines may charge a premium for their products. Buyers often consider brand reliability and after-sales service, which can justify a higher initial investment.

5. Customization and Features Customizable machines that can be tailored to specific production requirements can dramatically influence pricing. Additional features like automated cutting, punching capabilities, and integrated safety measures will add to the overall cost but can increase productivity and increase long-term value.

Market Trends and Economic Factors

Additionally, market trends and economic conditions can create fluctuations in prices. For example, rising raw material costs or supply chain disruptions can lead to increased prices for manufacturing equipment, including rolling shutter making machines. It's also vital for manufacturers to stay informed about market demand—an increase in the construction industry can boost the demand for rolling shutters, thus affecting prices for both the shutters and the machines used to make them.

Conclusion

In conclusion, the price of rolling shutter making machines is influenced by various factors, including machine specifications, production capacity, material compatibility, brand reputation, and market conditions. Companies looking to invest in such equipment should carefully consider these elements to ensure that their purchase aligns with their operational needs and budget constraints. By making informed decisions, manufacturers can effectively balance quality, performance, and cost, ultimately leading to greater profitability in the competitive market of rolling shutters.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025