Affordable Factory Prices for Corrugated Roof Sheet Production Machines

Understanding the Price of Corrugated Roof Sheet Machine A Comprehensive Guide

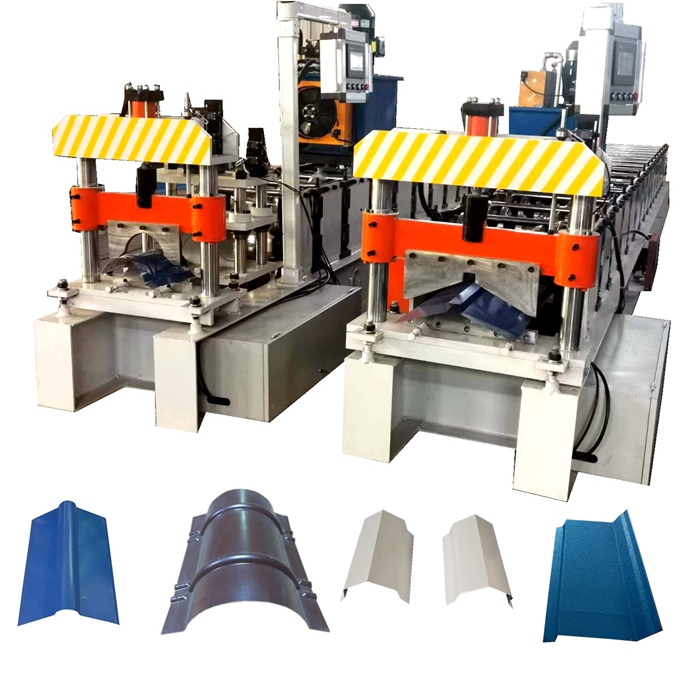

The demand for corrugated roof sheets has seen a significant rise in recent years due to their durability, cost-effectiveness, and aesthetic appeal. This has subsequently led to an increase in the production of corrugated roof sheet machines, which are essential for manufacturing these roofing materials. If you are considering investing in a corrugated roof sheet machine, understanding its pricing is critical. This article delves into the factors influencing the price of these machines and what you can expect when purchasing one from a factory.

Factors Influencing the Price of Corrugated Roof Sheet Machines

1. Machine Type and Specifications The complexity and specifications of the machine are primary determinants of its price. Basic models that produce standard sheets tend to be more affordable, while advanced machines equipped with features like automatic control systems, higher production speeds, and multiple product sizes come at a higher price. It's essential to assess your production needs before making a decision.

2. Material Quality The build quality of the machine itself can significantly impact its cost. Machines made from high-quality materials will generally have a higher upfront cost but may offer greater durability and longevity, resulting in lower long-term operational costs. Investing in robust machinery ensures minimal downtime and maintenance.

3. Production Capacity The capacity of the machine, measured in terms of output per hour, also influences its pricing. Machines designed for large-scale production will be more expensive than those intended for medium or small scale operations. Consider the volume of production you expect to achieve when selecting the right machine for your needs.

4. Brand Reputation Established brands often charge a premium for their machinery due to their reputation for quality and reliability. Conversely, newer or lesser-known brands may offer lower prices as they try to gain market traction. However, it's crucial to consider not just the price, but the after-sales service and support that come with the machinery.

corrugated roof sheet machine price factory

5. Technological Advancements The integration of technology into manufacturing processes has led to the development of more efficient machines. Machines that utilize modern technology can be more expensive initially, but they often result in cost savings over time due to reduced labor and energy consumption.

6. Location of the Factory The geographical location of the manufacturing facility can also affect pricing. Factories in regions with higher labor costs or stricter regulations may charge more for their machines. Conversely, factories in areas with lower operational costs could offer competitive pricing.

Estimated Price Range

The price of a corrugated roof sheet machine can vary widely based on the aforementioned factors. On average, you can expect to pay anywhere from $10,000 to $100,000. Basic models may start at the lower end of this spectrum, while advanced, fully automated machines can reach the upper limits. It's advisable to conduct thorough market research and compare prices from multiple manufacturers to find a machine that fits your budget and production requirements.

Conclusion

Investing in a corrugated roof sheet machine is a significant decision that requires careful consideration of various factors that influence its price. By understanding these factors, you can make an informed choice that aligns with your business goals. Always remember to prioritize quality and after-sales support, as these will contribute to the long-term success of your investment. With the right machine, you can boost your production efficiency and establish a competitive edge in the roofing market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025