Advanced Techniques in Sheet Metal Forming Machinery for Precision Manufacturing Processes

The Importance of Sheet Metal Forming Machines in Modern Manufacturing

Sheet metal forming machines play a crucial role in contemporary manufacturing processes. These advanced machines are designed to manipulate flat sheets of metal into specified shapes through various techniques such as bending, stretching, and cutting. Their versatility and efficiency make them indispensable for industries ranging from automotive to aerospace, and even in the production of household appliances.

One of the primary types of sheet metal forming machines is the press brake. This machine is widely used to bend metal sheets into desired angles and shapes. By applying pressure through a punch and die mechanism, press brakes can create precise bends that meet stringent specifications. The ability to produce complex geometries with accuracy makes this machine particularly valuable in prototyping and mass production. Furthermore, modern press brakes are equipped with CNC (Computer Numerical Control) technology, which enhances precision and allows for quick adjustments, reducing setup times for various tasks.

Another essential machine in the sheet metal forming arsenal is the shear. This device cuts through metal sheets efficiently, ensuring clean and straight edges. Shearing is vital for preparing metal sheets before further forming steps, and it can handle various materials, from aluminum to stainless steel. Coupled with laser cutting technology, which uses concentrated light beams to cut intricate designs, shearing machines provide manufacturers with exceptional flexibility in their production capabilities.

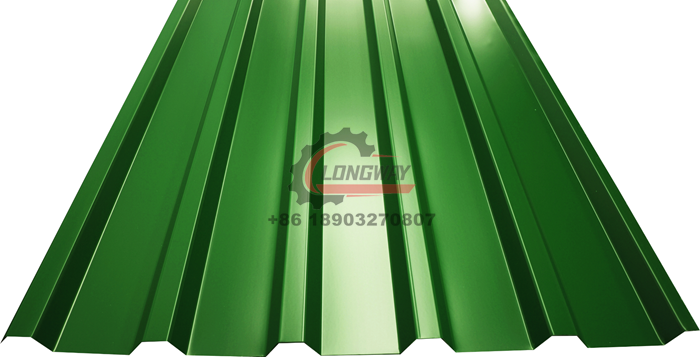

sheet metal forming machine

The process of metal forming is not limited to bending and cutting; it also includes advanced techniques such as stamping and hydroforming. Stamping involves pressing a sheet of metal using a die to create specific shapes or patterns. It is commonly used in the automotive industry for producing body panels and components. On the other hand, hydroforming utilizes high-pressure fluids to shape the metal, allowing for the creation of lightweight parts with complex geometries that are both strong and aesthetically pleasing.

One significant advantage of sheet metal forming machines is their ability to reduce material waste. Traditional manufacturing processes often result in excess scrap material, but modern machines utilize advanced techniques to maximize material usage. For instance, nesting software can optimize the layout of cuts and bends on a sheet, ensuring minimal waste. This not only reduces costs but also aligns with sustainable manufacturing practices, as companies aim to lower their environmental impact.

Moreover, automation plays a pivotal role in enhancing the productivity of sheet metal forming machines. Automated loading and unloading systems, along with robotic arms, streamline the entire process from start to finish. This integration of robotics reduces manual handling, minimizes human error, and ultimately accelerates production cycles. As a result, manufacturers can meet rising demands in a competitive market while maintaining high-quality standards.

In conclusion, sheet metal forming machines are integral to the efficiency and effectiveness of modern manufacturing. Their capability to shape and manipulate metal sheets into desired forms, combined with advancements in technology and automation, has transformed industries across the globe. As manufacturers continue to seek innovative solutions to enhance productivity and sustainability, the evolution of sheet metal forming machines will undoubtedly play a pivotal role in shaping the future of manufacturing. With ongoing research and development, we can expect even more sophisticated technologies to emerge, further optimizing this critical aspect of industrial production.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025