Advanced Roof Sheet Rolling Machine Solutions for Efficient and Durable Metal Roofing Production

The Evolution and Importance of Roof Sheet Rolling Machines in the Construction Industry

In today’s fast-paced construction world, the demand for efficient and reliable building materials has skyrocketed. Among these, roof sheets made from metals like steel and aluminum are particularly prized for their durability and aesthetic appeal. Behind the production of these essential materials, roof sheet rolling machines play a pivotal role. Understanding the evolution, functionality, and significance of these machines is crucial for anyone involved in the construction and manufacturing industries.

The Evolution of Roof Sheet Rolling Machines

Roof sheet rolling machines have a rich history, evolving from simple manual tools to sophisticated automated systems. Historically, metal sheets were manipulated by hand, leading to inefficiencies and inconsistent quality. However, with the advent of technology and mechanization in the 20th century, rolling machines were developed to automate this process. These machines have since advanced dramatically, utilizing Computer Numerical Control (CNC) technology to enhance precision and reduce labor costs.

Modern rolling machines are now equipped with features such as digital displays, automated adjustments, and the ability to produce a variety of profiles and thicknesses. This evolution has led to an increase in production speed and the capacity to meet diverse customer needs with high accuracy.

How Roof Sheet Rolling Machines Work

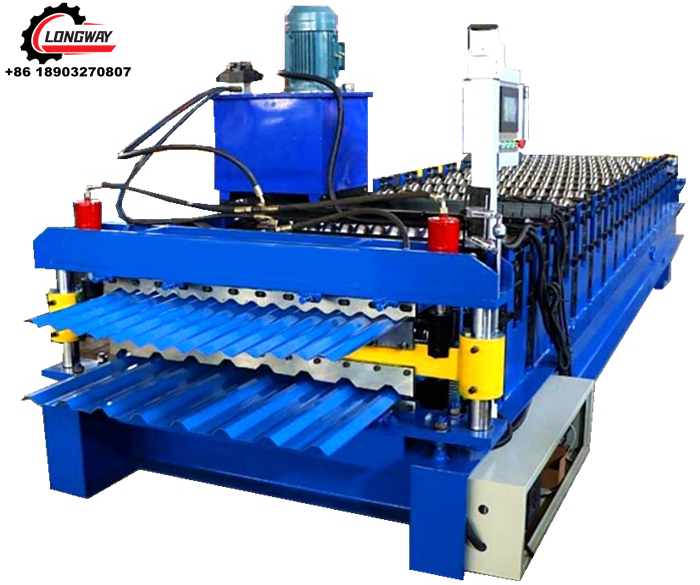

Roof sheet rolling machines operate through a series of rollers that shape metal sheets into the desired profile. The process begins with feeding flat metal coils into the machine. As the sheet passes through the rollers, it is gradually formed into specific shapes such as standing seam, corrugated, or trapezoidal profiles. The efficiency of these machines is remarkable; they can produce thousands of sheets in a single day, thereby fulfilling large construction projects swiftly.

roof sheet rolling machine company

The control systems integrated into these machines allow operators to customize thickness, width, and height of the sheets according to project requirements. This adaptability is crucial in catering to the unique needs of various buildings, whether industrial, commercial, or residential.

The Significance of Roof Sheet Rolling Machines

The importance of roof sheet rolling machines extends beyond mere production efficiency. First and foremost, they contribute significantly to the overall quality and longevity of roofing products. Roof sheets manufactured using advanced rolling technologies are resistant to weathering, corrosion, and other damages, ensuring a longer lifespan for buildings. This durability not only helps in reducing replacement costs but also contributes to sustainability by minimizing waste.

Moreover, the ability to produce customized sheet profiles means that architects and builders can design structures that are both functional and aesthetically pleasing. The flexibility in production allows for innovative designs that enhance the overall appeal and functionality of buildings.

Additionally, roof sheet rolling machines support the construction industry by streamlining supply chains. By enabling local production of roofing materials, these machines reduce the dependence on imported goods, contributing to lower costs and faster turnaround times. This localization of production aligns with the growing emphasis on sustainable practices, as shorter supply chains can help reduce the carbon footprint associated with transportation.

Conclusion

In conclusion, roof sheet rolling machines are an indispensable component of the modern construction industry. Their evolution has enabled greater efficiency, improved product quality, and enhanced design flexibility. As the industry continues to grow and innovate, these machines will undoubtedly play a crucial role in fulfilling the increasing demand for high-quality roofing materials. The future of construction hinges on such technological advancements, making the significance of roof sheet rolling machines more pronounced than ever.

-

the-role-of-hydraulic-systems-in-sheet-metal-slittersNewsAug.23, 2025

-

customization-options-in-metal-deck-roll-forming-machinesNewsAug.23, 2025

-

safety-tips-when-using-a-gutter-making-machineNewsAug.23, 2025

-

key-components-of-a-c-purlin-machine-explainedNewsAug.23, 2025

-

maintenance-tips-for-a-steel-angle-roll-forming-machineNewsAug.23, 2025

-

portable-metal-roofing-machine-applications-in-remote-constructionNewsAug.23, 2025

-

Roof Panel MachineNewsAug.18, 2025