Advanced Ceiling Batten Roll Forming Solutions for Efficient and High-Quality Production Processes

The Innovative Ceiling Batten Roll Forming Machine Enhancing Production Efficiency

The construction industry continuously seeks innovative solutions to improve efficiency and productivity. One notable advancement is the ceiling batten roll forming machine, a cutting-edge piece of equipment designed to streamline the production process of ceiling battens, an essential component in modern building interiors.

What is a Ceiling Batten?

Ceiling battens are narrow strips of material, typically made from metal, wood, or plastic, that serve as a framework for ceiling installations. They are crucial in supporting various ceiling types, providing both stability and aesthetic appeal. In recent years, the demand for ceiling battens has surged due to the increasing popularity of suspended ceiling systems, which enhance acoustics, insulation, and overall design flexibility.

The Mechanics of Roll Forming

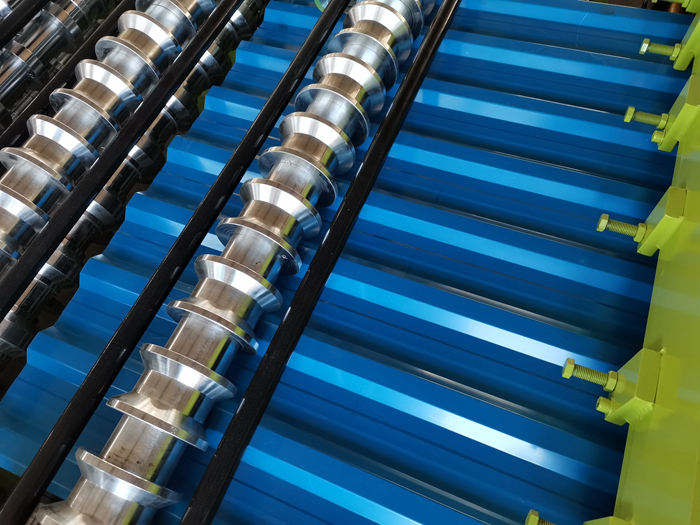

Roll forming is a continuous bending process in which a long strip of metal is gradually shaped into a desired cross-section by passing it through a series of rollers. This method is particularly effective for producing long lengths of uniform products like ceiling battens. The ceiling batten roll forming machine operates by drawing a coil of metal sheet through multiple sets of rollers, carefully designed to shape the material precisely into the required profile.

Key Features of Ceiling Batten Roll Forming Machines

1. High Efficiency and Speed One of the most significant advantages of these machines is their ability to produce ceiling battens at high speeds. Depending on the model, production rates can reach up to several hundred meters per hour, allowing manufacturers to meet growing market demands without compromising quality.

ceiling batten roll forming machine

2. Customization Options Modern roll forming machines offer customization capabilities, enabling manufacturers to produce a wide range of batten profiles and sizes. This flexibility is crucial for contractors who often require specific dimensions to match various design specifications.

3. Durability and Cost-Effectiveness Ceiling batten roll forming machines are built to last, often constructed using high-strength materials and advanced engineering techniques. This durability translates into lower maintenance costs over time. Additionally, the efficiency of the process reduces material waste, contributing to overall cost savings in production.

4. Automation and Control Today’s machines incorporate advanced automation systems that enhance precision and reduce labor costs. Digital control panels allow for easy adjustments and monitoring of production parameters, ensuring that the finished products meet the required standards consistently.

Benefits to Manufacturers and Contractors

For manufacturers, the ceiling batten roll forming machine represents an opportunity to streamline operations and improve production efficiency, ultimately leading to increased profitability. The ability to produce high-quality battens quickly and efficiently opens up new market opportunities and attracts a broader customer base.

Contractors also benefit significantly. With a reliable supply of customized ceiling battens, they can expedite projects and enhance the quality of their constructions. The precision provided by roll forming ensures that the installation process is smoother, reducing the likelihood of costly rework or delays on-site.

Conclusion

The ceiling batten roll forming machine epitomizes the technological advancements reshaping the construction industry. By enhancing efficiency, providing customization options, and reducing costs, it plays a pivotal role in meeting the demands of modern building projects. As construction techniques evolve and the need for innovative solutions grows, these machines will continue to be indispensable tools for manufacturers and contractors alike. Embracing such technology is not just about staying competitive; it's about driving the future of construction productivity.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025