Jun . 28, 2024 06:10

Back to list

Advanced C Purlin Rolling Machinery for Efficient Steel Fabrication

Understanding the Functionality and Importance of C Purlin Rolling Machines

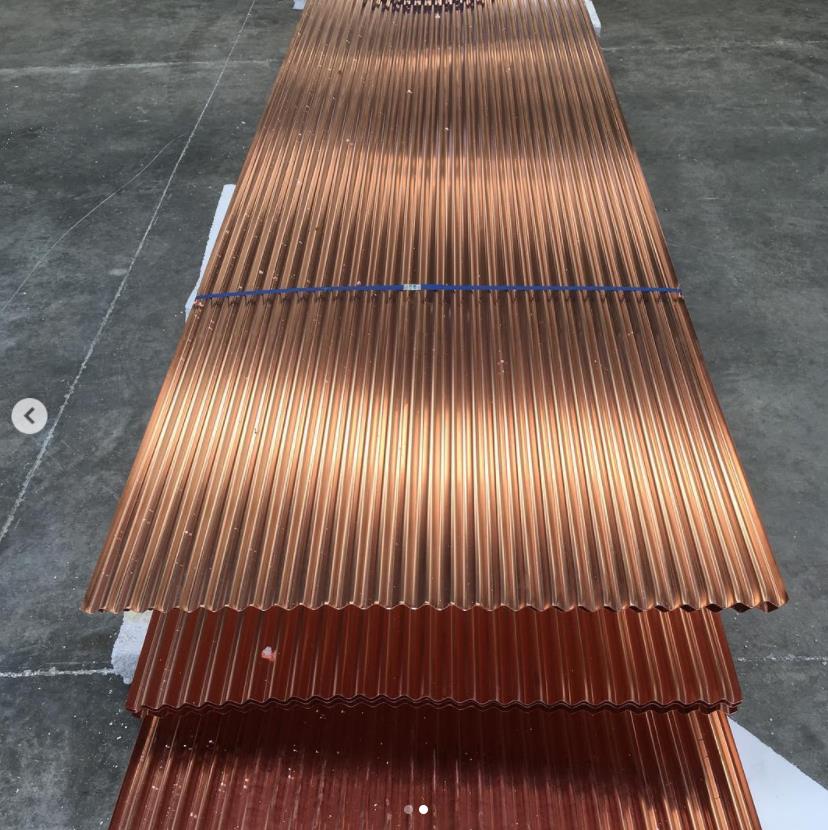

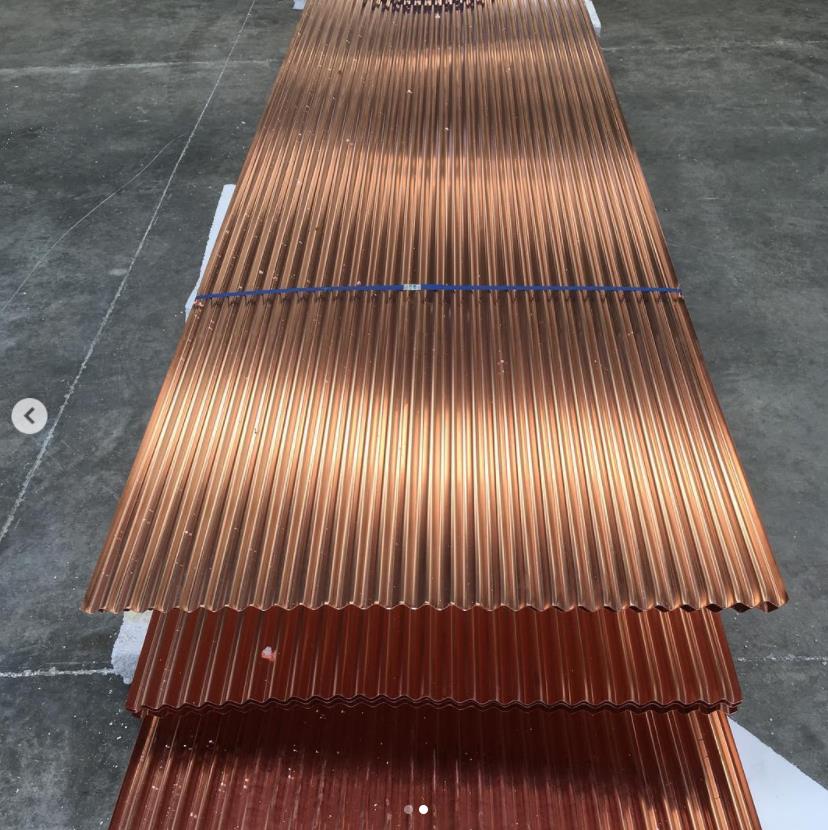

In the realm of steel fabrication and construction, a C Purlin Rolling Machine holds a significant position due to its efficiency and precision in manufacturing C-shaped purlins. Purlins, typically made from steel, are essential structural components used in roofing and wall systems, providing support for the roof cladding. The C Purlin Rolling Machine is specifically designed to streamline this process, offering a high-speed and cost-effective solution.

A C Purlin Rolling Machine, also known as a C Section Roll Forming Machine, is an advanced piece of machinery that automates the production of C-shaped purlins with remarkable accuracy. The 'C' shape refers to the profile of the purlin, resembling the letter 'C' when viewed from one end. These machines are engineered to roll and form steel strips into the desired C-shape, making them indispensable tools in industrial workshops and manufacturing plants.

The operation of a C Purlin Rolling Machine involves a series of processes. Initially, a metal sheet is fed into the machine, where it passes through a set of rollers arranged in a specific sequence. Each roller performs a unique bending action, gradually shaping the sheet into the C-profile. The speed and pressure of the rollers are precisely controlled, ensuring consistent quality and dimensions of the final product.

One of the key advantages of using a C Purlin Rolling Machine is its capacity for customization

One of the key advantages of using a C Purlin Rolling Machine is its capacity for customization One of the key advantages of using a C Purlin Rolling Machine is its capacity for customization

One of the key advantages of using a C Purlin Rolling Machine is its capacity for customization

One of the key advantages of using a C Purlin Rolling Machine is its capacity for customization

One of the key advantages of using a C Purlin Rolling Machine is its capacity for customization c purlin rolling machine. Users can easily adjust the machine settings to produce purlins of varying sizes and thicknesses, catering to diverse project requirements. This adaptability not only saves time but also reduces material waste, making it an environmentally friendly option.

Moreover, the efficiency of a C Purlin Rolling Machine significantly increases productivity. With its automated operation, it can produce a large number of purlins in a short period, reducing labor costs and enhancing overall workshop efficiency. The machine's robust design, combined with its ability to handle heavy loads, ensures durability and longevity in even the most demanding environments.

In conclusion, the C Purlin Rolling Machine is a testament to the integration of technology and innovation in the construction industry. It plays a pivotal role in streamlining the production of purlins, thereby expediting construction timelines and reducing costs. As the demand for faster and more sustainable building solutions continues to rise, the importance of such specialized machinery will only increase, shaping the future of steel fabrication and construction.

c purlin rolling machine. Users can easily adjust the machine settings to produce purlins of varying sizes and thicknesses, catering to diverse project requirements. This adaptability not only saves time but also reduces material waste, making it an environmentally friendly option.

Moreover, the efficiency of a C Purlin Rolling Machine significantly increases productivity. With its automated operation, it can produce a large number of purlins in a short period, reducing labor costs and enhancing overall workshop efficiency. The machine's robust design, combined with its ability to handle heavy loads, ensures durability and longevity in even the most demanding environments.

In conclusion, the C Purlin Rolling Machine is a testament to the integration of technology and innovation in the construction industry. It plays a pivotal role in streamlining the production of purlins, thereby expediting construction timelines and reducing costs. As the demand for faster and more sustainable building solutions continues to rise, the importance of such specialized machinery will only increase, shaping the future of steel fabrication and construction.

One of the key advantages of using a C Purlin Rolling Machine is its capacity for customization

One of the key advantages of using a C Purlin Rolling Machine is its capacity for customization

One of the key advantages of using a C Purlin Rolling Machine is its capacity for customization

One of the key advantages of using a C Purlin Rolling Machine is its capacity for customization c purlin rolling machine. Users can easily adjust the machine settings to produce purlins of varying sizes and thicknesses, catering to diverse project requirements. This adaptability not only saves time but also reduces material waste, making it an environmentally friendly option.

Moreover, the efficiency of a C Purlin Rolling Machine significantly increases productivity. With its automated operation, it can produce a large number of purlins in a short period, reducing labor costs and enhancing overall workshop efficiency. The machine's robust design, combined with its ability to handle heavy loads, ensures durability and longevity in even the most demanding environments.

In conclusion, the C Purlin Rolling Machine is a testament to the integration of technology and innovation in the construction industry. It plays a pivotal role in streamlining the production of purlins, thereby expediting construction timelines and reducing costs. As the demand for faster and more sustainable building solutions continues to rise, the importance of such specialized machinery will only increase, shaping the future of steel fabrication and construction.

c purlin rolling machine. Users can easily adjust the machine settings to produce purlins of varying sizes and thicknesses, catering to diverse project requirements. This adaptability not only saves time but also reduces material waste, making it an environmentally friendly option.

Moreover, the efficiency of a C Purlin Rolling Machine significantly increases productivity. With its automated operation, it can produce a large number of purlins in a short period, reducing labor costs and enhancing overall workshop efficiency. The machine's robust design, combined with its ability to handle heavy loads, ensures durability and longevity in even the most demanding environments.

In conclusion, the C Purlin Rolling Machine is a testament to the integration of technology and innovation in the construction industry. It plays a pivotal role in streamlining the production of purlins, thereby expediting construction timelines and reducing costs. As the demand for faster and more sustainable building solutions continues to rise, the importance of such specialized machinery will only increase, shaping the future of steel fabrication and construction. Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products