Advanced C Purlin Forming Machine for Efficient Steel Structure Production and Customization Solutions

The Importance of C Purlin Forming Machines in Modern Construction

In the realm of modern construction, the efficiency and quality of materials play a critical role in determining the success of any project. Among these materials, C purlins have emerged as a vital component due to their strength, versatility, and cost-effectiveness. Central to the production of C purlins is the C purlin forming machine, a piece of machinery that streamlines the manufacturing process and ensures a consistent supply of high-quality steel components.

What are C Purlins?

C purlins are horizontal structural members used primarily in the construction of roofs and wall structures. They are named for their C-shaped cross-section and are typically made from various grades of steel, such as cold-formed steel or hot-rolled steel. C purlins provide excellent load-bearing capabilities and are particularly favored in the construction of industrial buildings, warehouses, and commercial facilities. They are also used in the framework of pre-engineered buildings, making them a staple in modern construction practices.

The Role of C Purlin Forming Machines

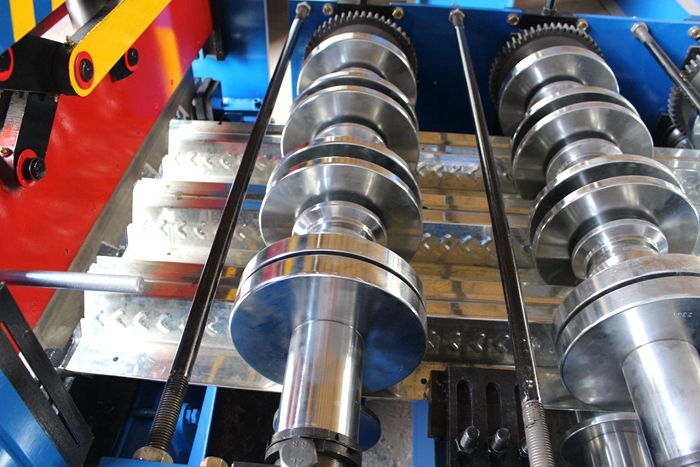

C purlin forming machines are specially designed to convert flat steel sheets into C-shaped purlins through a series of precise bending and cutting processes. These machines utilize advanced technologies including roll forming, which involves passing the flat steel through a series of rollers that gradually shape it into the desired profile. The process not only ensures uniformity in dimensions but also enhances the structural integrity of the final product.

One of the significant advantages of using a C purlin forming machine is the ability to produce purlins in various sizes and thicknesses. This adaptability allows manufacturers to cater to a wide range of construction projects, each with its unique specifications. Additionally, automated C purlin forming machines are available, which minimize human intervention and improve production efficiency.

Benefits of Using C Purlin Forming Machines

c purlin forming machine

1. Precision and Quality C purlin forming machines ensure that each purlin produced meets stringent quality standards. The automated processes reduce the likelihood of human errors, resulting in high precision and uniformity across all units.

2. Cost-Effectiveness By automating the production process, manufacturers can significantly reduce labor costs and material waste. This efficiency translates to lower production costs, allowing for more competitive pricing in the market.

3. Versatility Advanced forming machines can produce different styles and sizes of C purlins, making them suitable for various applications. This versatility is crucial in meeting the diverse needs of clients and adapting to changing market demands.

4. Speed of Production C purlin forming machines are capable of rapid production, enabling manufacturers to respond quickly to market needs. This speed is particularly beneficial in large-scale construction projects where timely delivery of materials is crucial.

5. Durability The machines can process high-quality steel, which ensures that the C purlins produced are durable and capable of withstanding various environmental conditions. This durability is essential for the long-term success of construction projects.

Conclusion

As the construction industry continues to evolve, the importance of efficient and reliable manufacturing processes cannot be overstated. C purlin forming machines are at the forefront of this transformation, providing essential solutions for producing high-quality structural components. With their precision, cost-effectiveness, and versatility, these machines not only enhance productivity but also contribute significantly to the overall quality of construction projects. As builders and manufacturers seek to improve efficiency and sustainability, investing in advanced C purlin forming machines is a step in the right direction. Thus, they remain an invaluable asset in the modern construction landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025