Advanced C Channel Fabrication Equipment for Efficient Metal Processing and Production Solutions

The Transformation of Production C Channel Making Machines

In the ever-evolving landscape of industrial manufacturing, efficiency, precision, and versatility are paramount. One of the remarkable innovations that have significantly impacted the production sector is the C channel making machine. This versatile piece of equipment has redefined how C channels, a vital component in construction and other industries, are produced. From automated processes to the ability to handle various materials, C channel making machines are a testament to modern engineering and manufacturing capabilities.

Understanding C Channels

C channels, also known as C beams or C sections, are structural components shaped like the letter “C.” They are commonly used in a variety of applications, including building frameworks, support structures, and even in the automobile industry. The distinctive shape allows for immense strength and durability while maintaining a relatively lightweight profile. As demand for C channels grows, the need for efficient production methods has become increasingly clear.

The Role of C Channel Making Machines

C channel making machines are specialized equipment designed to produce C channels rapidly and consistently. These machines typically function through a roll forming process, where flat metal strips are fed into a series of rollers that gradually shape the material into the desired C section. The precision of these machines allows for uniform dimensions and high-quality finishes, which are essential for structural integrity in construction.

One of the most significant benefits of C channel making machines is their automation capabilities. Many modern machines are equipped with advanced technology, such as programmable logic controllers (PLCs) and computer numerical control (CNC) systems. This automation not only enhances precision but also reduces the amount of manual labor required, allowing manufacturers to operate more efficiently and reduce production costs.

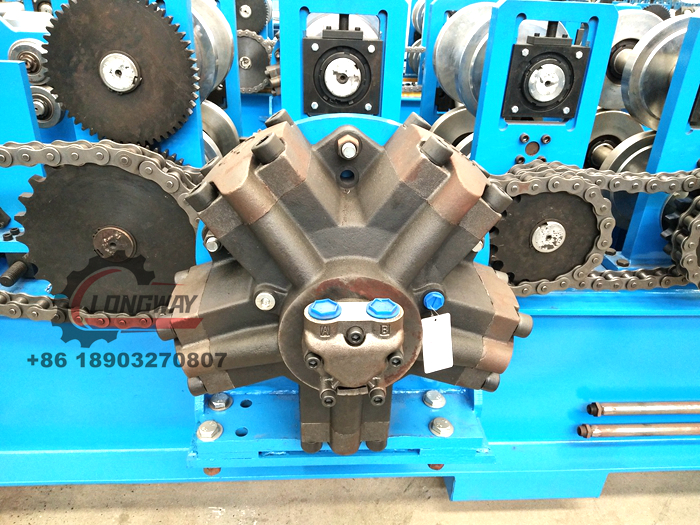

c channel making machine

Customization and Material Flexibility

Another key advantage of C channel making machines is their ability to accommodate a range of materials. While steel is the most commonly used material, these machines can also process aluminum, stainless steel, and other alloys. This flexibility enables manufacturers to cater to diverse customer requirements and market demands.

Moreover, C channel making machines can be customized to produce channels of varying sizes and thicknesses, providing manufacturers with the versatility to adapt to different projects and specifications. This capability is particularly beneficial in industries where bespoke solutions are necessary, such as construction and infrastructure development.

Environmental Considerations

As industries strive for sustainability, C channel making machines have also evolved to be more environmentally friendly. Many modern machines are designed to minimize waste by optimizing the roll forming process, ensuring that the maximum amount of material is utilized. Additionally, advancements in energy efficiency mean that these machines consume less power, reducing the carbon footprint associated with their operation.

Conclusion

In summary, C channel making machines represent a significant advancement in the manufacturing sector. Their ability to produce high-quality C channels efficiently and accurately has transformed how structural components are manufactured. With the integration of automation, customization, and environmental considerations, C channel making machines are not only meeting current industry demands but also paving the way for a more sustainable and efficient future in manufacturing. As technology continues to advance, we can expect these machines to become even more sophisticated, further enhancing their contribution to the construction and industrial sectors.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025