Advanced Automatic Roll Forming Machine for Efficient Metal Profile Production and Customization Solutions

The Evolution and Benefits of Full Automatic Roll Forming Machines

In the realm of modern manufacturing, efficiency and precision are paramount. One of the most significant innovations contributing to these goals is the full automatic roll forming machine. This sophisticated equipment has revolutionized the production of metal profiles, significantly enhancing the manufacturing capabilities of industries across the globe.

Understanding Full Automatic Roll Forming Machines

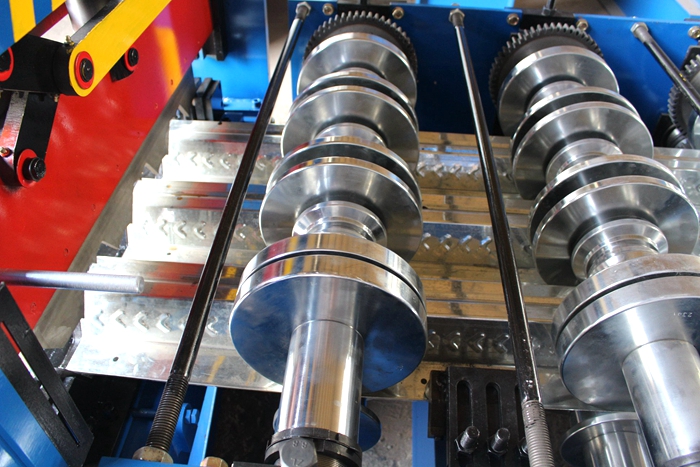

Full automatic roll forming machines are designed to convert flat metal sheets into intricate shapes and profiles through a series of progressive forming stations. The process begins with feeding a flat strip of material, typically metal, into the machine. As the material passes through a series of rollers, it undergoes continuous deformation, resulting in the desired shape. This technology is widely used for producing items such as roofing sheets, wall panels, and various structural components.

Key Advantages

1. High Efficiency One of the most compelling benefits of full automatic roll forming machines is their high level of efficiency. Unlike manual or semi-automatic systems, these machines can operate continuously. This leads to a significant reduction in production time and increases output, allowing manufacturers to meet high demand without compromising quality.

2. Precision Engineering In industries where precision is crucial, full automatic roll forming machines shine. They are designed with advanced control systems that ensure consistent dimensional accuracy throughout the production process. This precision minimizes waste, reduces the need for rework, and enhances the overall quality of the finished products.

full automatic roll forming machine

3. Flexibility Modern roll forming machines come with advanced features that allow manufacturers to produce a wide range of profiles with minimal downtime. Quick-change tooling options enable seamless transitions between different product designs, making it easy to adapt to changing market demands. This flexibility is particularly valuable in today's fast-paced manufacturing environment.

4. Cost-Effectiveness Although the initial investment in a full automatic roll forming machine may be substantial, the long-term savings are significant. The reduction in labor costs, coupled with increased production speeds and minimized waste, translates to lower overall manufacturing costs. Businesses can achieve a higher return on investment while maintaining high quality standards.

5. Automation and Smart Technology The integration of automation and smart technology into full automatic roll forming machines further enhances their capabilities. Features such as computer numerical control (CNC) allow for precise programming and monitoring of the production process. Some machines are equipped with sensors and data analytics, providing real-time insights that can be used to optimize performance and predict maintenance needs.

Applications Across Industries

Full automatic roll forming machines are used in various industries, including construction, automotive, and appliance manufacturing. In the construction sector, they are crucial for producing metal roofing and siding, ensuring that building materials are not only durable but also aesthetically pleasing. In the automotive industry, these machines create components that require high strength-to-weight ratios, vital for modern vehicle design.

Conclusion

The full automatic roll forming machine represents a significant leap forward in manufacturing technology. With their impressive efficiency, precision, and flexibility, these machines have become essential tools for manufacturers aiming to enhance productivity and maintain competitiveness in the global marketplace. As technology continues to evolve, the future of roll forming looks promising, heralding an era of even greater innovation and sustainability in manufacturing processes.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025