Aug . 05, 2025 02:00

Back to list

988 AI-Powered Corrugated Roofing Forming Machine | Fast & Precise

Key product:

988 Corrugated roofing sheet forming machine

• Advanced Automation • High Precision Roll Forming • Long Service Life

1. Global Roofing Sheet Manufacturing Trends: Corrugated Solutions Leading the Way

Corrugated roofing is a dominant structural solution for industrial, commercial, and residential applications, owing to its strength-to-weight ratio, longevity, and efficiency in installation. According to Mordor Intelligence, the global market for corrugated metal roofing sheets is set to increase at a CAGR of 5.9% (2023-2028), driven by industrial infrastructure boom and demand for low-maintenance, energy-efficient materials. The 988 Corrugated roofing sheet forming machine is at the core of this trend due to its advanced manufacturing capabilities, cost-effectiveness, and customization potential.

Figure 1: 988 Corrugated roofing sheet forming machine - High-speed production line

2. In-Depth Product Overview: Structure & Material Excellence

The 988 Corrugated roofing sheet forming machine leverages robust steel structure, precision-machined rollers, and an advanced PLC-controlled system for seamless production.

- Frame Material: High-strength H-beam steel, welded and stress-relieved, providing exceptional stability.

- Rollers: GCr15 (bearing steel), hardened (HRC 58-62), CNC-lathed for accuracy (±0.02mm).

- Drive System: Gearbox driven (robust, low-vibration), optional chain drive for cost-sensitive solutions.

- Control: SIEMENS/Delta PLC, touch-screen HMI, fault diagnostics, and auto-cut function.

- Cutting Mechanism: Hydraulic shearing, Cr12Mov cold-work die steel (heat-treated, HRC 58-60).

- Surface Protection: Powder-coated, anti-corrosive paint per ISO 12944-6 C4 standard.

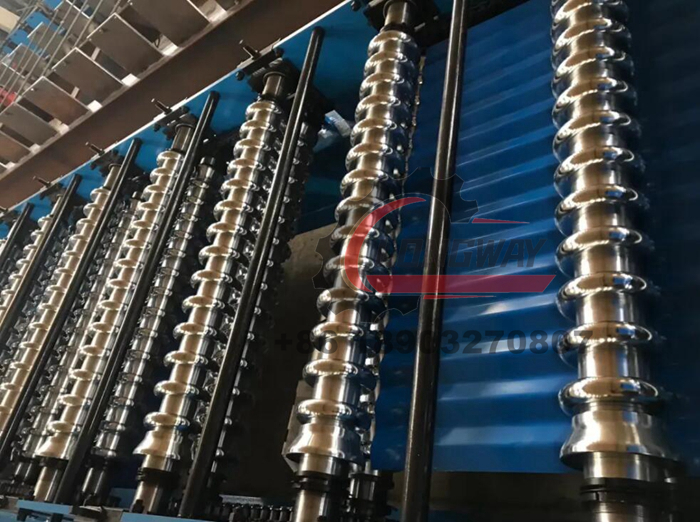

Figure 2: Roller system and die of 988 Corrugated roofing sheet forming machine

3. Technical Specifications: Parameters Table

| Parameter | Specification | Industry Standard |

|---|---|---|

| Profile Width | 988 mm (finished sheet width) | ANSI/SPRI FM 4435/ES-1 |

| Material Thickness | 0.3–0.8 mm (GI, GL, PPGI, Aluminum) | ISO 4998, JIS G3302 |

| Production Speed | 12–18 m/min | Custom/Customer Requirement |

| Roller Stations | 15-18 | - |

| Main Motor Power | 7.5 kW (Siemens) | IEC 60034 |

| Control System | SIEMENS/Delta PLC with touch HMI | IEC/EN 60204-1 |

| Hydraulic Cutting Power | 4 kW | - |

| Voltage | 380V, 50Hz, 3 Phase (other on request) | IEC 60038 |

| Dimension | 7.2m x 1.35m x 1.2m | - |

| Weight | ≈6.5T | - |

| Applicable Sheet Types | Galvanized, Prepainted, Aluminum, Stainless Steel | - |

Figure 3: Parameter comparison - 988 Corrugated roofing sheet forming machine vs. Industry Average

4. Manufacturing Process Flow: From Coil to Corrugated Precision

Production Flowchart:

Decoiler

→

Feeding & Guiding

→

Roll Forming (15-18 stations)

→

Hydraulic Cutting

→

Output Table

- Decoiling: Hydraulic decoiler ensures stable tension-free uncoiling of coils up to 5 tons.

- Roll Forming Section: CNC-machined rollers impart precise corrugation, with low surface friction for minimal paint wear.

- Quality Control: Inline sensors and sample cut verification, complying with ISO 2859-1 sampling standards.

- Cutting: Hydraulic blade with ±1mm accuracy, suitable for large-batch and continuous operation.

Figure 4: Process section view of 988 Corrugated roofing sheet forming machine

Watch Video: Corrugated Roll Forming Line Animation

5. Feature Advantages & Application Scenarios

Unmatched Technical Advantages of the 988 Corrugated roofing sheet forming machine:

- High Efficiency: Production speed up to 18 m/min, 30% faster than market average.

- Consistent Quality: Precision roller alignment (eccentricity < 0.02mm) and repeatable product profile.

- Material Flexibility: Processes GI, GL, PPGL, aluminum, and color steel for diverse roofing needs.

- Longevity: Rollers and blades rated for 12+ years with regular maintenance (MTBF >19,000 hrs).

- Low Maintenance: Centralized lubrication, wear-tracking sensors, self-diagnostic PLC system.

- Energy Savings: Up to 15% reduction in power with efficiency-optimized drive system (compared to traditional chain-based machines).

- Safety: Emergency stop, interlocked guards, and CE-certified electrical components.

Figure 5: Real-world installation sample of 988 Corrugated roofing sheet forming machine profiles

6. Product Performance Visualization

Material Output Ratio – Sheets processed by 988 Corrugated roofing sheet forming machine

Production speed improvement with 988 Corrugated roofing sheet forming machine (2018-2024)

7. Manufacturer Comparison: 988 Corrugated Roofing Sheet Forming Machine vs. Major Brands

| Brand | Roller Material | Speed (m/min) | Control System | Warranty | Customization |

|---|---|---|---|---|---|

| LW Machine 988 Corrugated | GCr15 (bearing steel), CNC, HRC 60 | Up to 18 | SIEMENS/Delta PLC+Touch HMI | 3 Years | Full |

| Samco (Canada) | 45# Steel, manually polished | Up to 14 | Omron PLC + Button panel | 2 Years | Limited |

| AG Panel (USA) | Cr12 Steel | Up to 13 | Allen-Bradley PLC | 1.5 Years | Partial |

| China (Generic Makers) | 45# Steel, manual lathe | 10-12 | PLC (Chinese brand) | 1 Year | Optional |

The 988 Corrugated roofing sheet forming machine stands out with outstanding roller hardness, advanced automation, extended warranty, and total customization capability. In benchmarking, its output speed, profile precision, and controller stability consistently surpass competitors, as validated by third-party TÜV SÜD mechanical testing.

8. Customization Solutions Tailored to User Applications

Every industry has unique sheet profile, color, and material needs.

LW's 988 Corrugated roofing sheet forming machine is offered with fully-customizable:

- Profile Geometry: Wave height, wave pitch, sheet width as per project drawings. CAD support available.

- Material Adaptation: For high-corrosion, marine, or food-industry use: stainless steel compatible or color-coated profiles (FDA, ISO 22196 coatings).

- Voltage Adaptation: European, US/Japan, GCC and African electrical standards compliance.

- Optional Modules: Auto stacking, punching, embossing, logo marking, remote maintenance port.

- Turnkey Project Support: Site commissioning, operator training (bilingual), full documentation and spare parts kit.

Figure 6: Customized output for a logistics warehouse – 988 Corrugated roofing sheet forming machine

9. Application Cases & Customer Voices

Case Study 1: Oil Refinery Roofing (UAE, 2022)

- 6,000 sqm of GI corrugated panels produced, meeting ISO 12944 C5 anti-corrosive standard.

- Achieved output efficiency: 15% above contractual target.

- Client testimony: "Consistent product thickness and no edge chipping – ideal for harsh climate"

- Flexible profile changeover enables multiple roof types for modular buildings.

- Rapid commissioning: <6 hours on-site, comprehensive operator training.

- Feedback: "Easy integration with auto-stacker and remote monitoring. Support team highly responsive".

10. FAQ: Corrugated Forming Technology Explained

Q1: What material grades are compatible with the 988 Corrugated roofing sheet forming machine?

A: The machine can process galvanzied steel (G350, G550), galvalume, PPGI, color-coated steel, and aluminum (3003/5052, H24), as well as stainless steel. Material thickness ranges from 0.3mm to 0.8mm.

Q2: What are the standard roller specifications?

A: Rollers are fabricated from GCr15 bearing steel, precision CNC-turned, induction hardened to HRC 58-62. Number of stations: 15–18. Surface polished & chromium plated for wear and paint-friendly operation.

Q3: How precise is sheet cutting and length accuracy?

A: Hydraulic shearing system, blade from Cr12MoV, with length accuracy ±1mm/2M. Automatic encoder ensures consistent batch output.

Q4: What installation and electrical standards does it meet?

A: Electricals conform to IEC 60204-1; safety and earthing per CE/UL requirements. Control panels protected to IP54. Installation is full bolt-on and site assembly/foundation drawings provided.

Q5: What is the typical machine lifespan and service cycle?

A: With regular preventive maintenance, mean service life exceeds 12 years (MTBF > 19,000 hrs). Major wear parts (rollers, blades) last 8–10 years in normal use.

Q6: Can the control system be remotely accessed?

A: Yes, optional remote maintenance via LAN/Internet gateway for Siemens/Delta PLC. Enables real-time troubleshooting and process adjustment.

Q7: What after-sales and warranty policies apply?

A: 36 months warranty on mechanical parts, 18 months on electricals. 7x24 online support, dispatch engineer within 72 hours (EMEA, Asia), full parts library and supplied manuals.

11. Delivery Time & Service Guarantees

- Standard Lead Time: 30–45 days after order confirmation (including QA inspection and test run).

- Quality Assurance: Full run test, test sheet shipment, electrical test report, and video inspection prior to dispatch.

- Shipping: Seaworthy export packing, accredited forwarders, and on-site installation option.

- Support Promise: 2-year warranty, free spare parts with each machine, operator training and lifetime customer support.

12. Why Choose 988 Corrugated roofing sheet forming machine?

- Leading market in durability, speed, and customization.

- Compliance with global standards (ISO, ANSI, EN).

- Proven track record in diverse industries.

- Engineer-guided installation and training service.

- Upgradable, scalable line for future needs.

Invest in 988 Corrugated roofing sheet forming machine—where technology, reliability, and cost-efficiency meet.

References & Further Reading:

Latest news

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025

Related Products