Jan . 10, 2025 11:54

Back to list

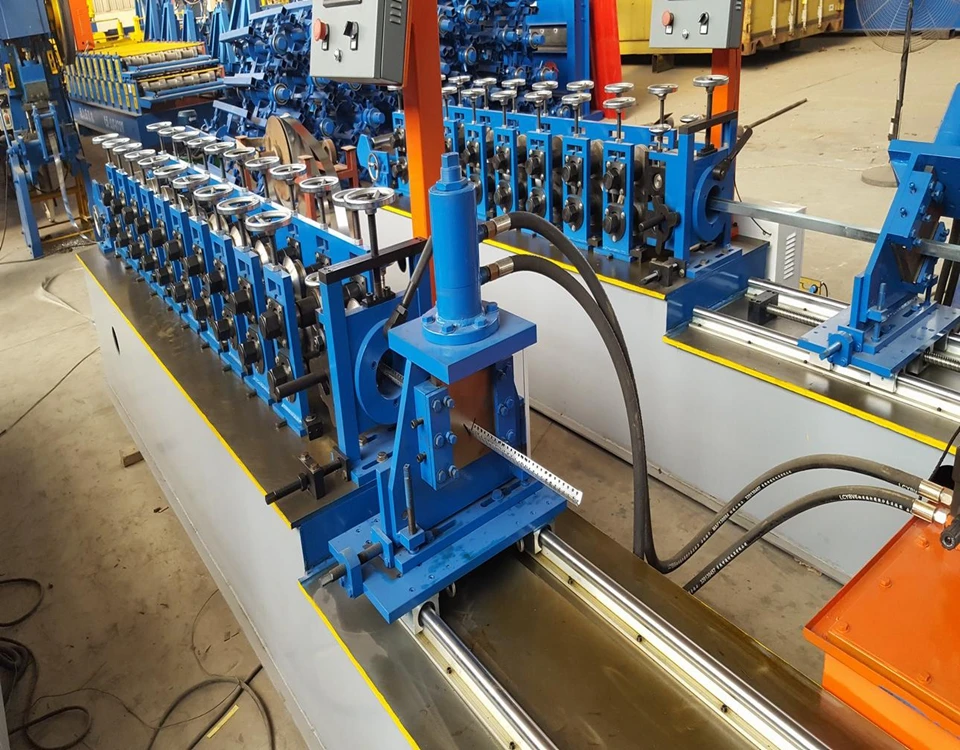

750 Trapezoidal Cladding wall panel forming machine

A wall angle roll forming machine is an indispensable asset in modern construction, favored for its ability to deliver consistent and precise metal bending and shaping. The machine is specially designed to produce wall angle sections, often used in ceiling frameworks, partition walls, and various other architectural and structural applications. Employing advanced roll forming technology, this machine transforms metal coils into angled sections that meet stringent industrial standards.

Trustworthiness in the production of wall angle sections is crucial for construction projects. Inferior or out-of-spec components can lead to structural issues, but with a reliable wall angle roll forming machine, manufacturers can consistently produce high-quality components. The trust placed in these machines is evidenced by their widespread use in commercial, residential, and industrial projects worldwide. In investing in a wall angle roll forming machine, consideration should be given to the machine’s build quality, ease of use, and manufacturer support. Machines constructed with durable materials and high-quality components tend to have longer service lives and lower maintenance requirements. Moreover, manufacturers who provide comprehensive training and after-sales support ensure that their machines continue to perform efficiently throughout their lifespan. For businesses looking to optimize production, understanding the capabilities of a wall angle roll forming machine is essential. Leveraging its efficiency can lead to increased profitability, faster project completion times, and the ability to take on more significant and more complex projects. Ultimately, these machines not only enhance productivity but also contribute to a higher standard of work in the construction industry, aligning perfectly with the goals of reliability and excellence.

Trustworthiness in the production of wall angle sections is crucial for construction projects. Inferior or out-of-spec components can lead to structural issues, but with a reliable wall angle roll forming machine, manufacturers can consistently produce high-quality components. The trust placed in these machines is evidenced by their widespread use in commercial, residential, and industrial projects worldwide. In investing in a wall angle roll forming machine, consideration should be given to the machine’s build quality, ease of use, and manufacturer support. Machines constructed with durable materials and high-quality components tend to have longer service lives and lower maintenance requirements. Moreover, manufacturers who provide comprehensive training and after-sales support ensure that their machines continue to perform efficiently throughout their lifespan. For businesses looking to optimize production, understanding the capabilities of a wall angle roll forming machine is essential. Leveraging its efficiency can lead to increased profitability, faster project completion times, and the ability to take on more significant and more complex projects. Ultimately, these machines not only enhance productivity but also contribute to a higher standard of work in the construction industry, aligning perfectly with the goals of reliability and excellence.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products