6 half round gutter machine companies

Exploring the 6% Half Round Gutter Machine Companies

In the realm of construction and roofing, the efficiency and effectiveness of water drainage systems cannot be overstated. Among the various options available, half round gutters have gained popularity for their aesthetic appeal and remarkable performance. To manufacture these essential components, specialized machinery is required, leading us to explore the companies that produce 6% half round gutter machines. This article will delve into what these machines are, their significance, and highlight some key players in the industry.

Understanding Half Round Gutter Machines

Half round gutters are characterized by their semicircular shape, which not only adds a classic touch to buildings but also promotes superior water flow compared to square or rectangle gutters. A 6% half round gutter machine is specifically designed to create these gutters with precision and efficiency. The 6% typically refers to the pitch or slope that these gutters need to have to effectively channel water away from the roof and foundation.

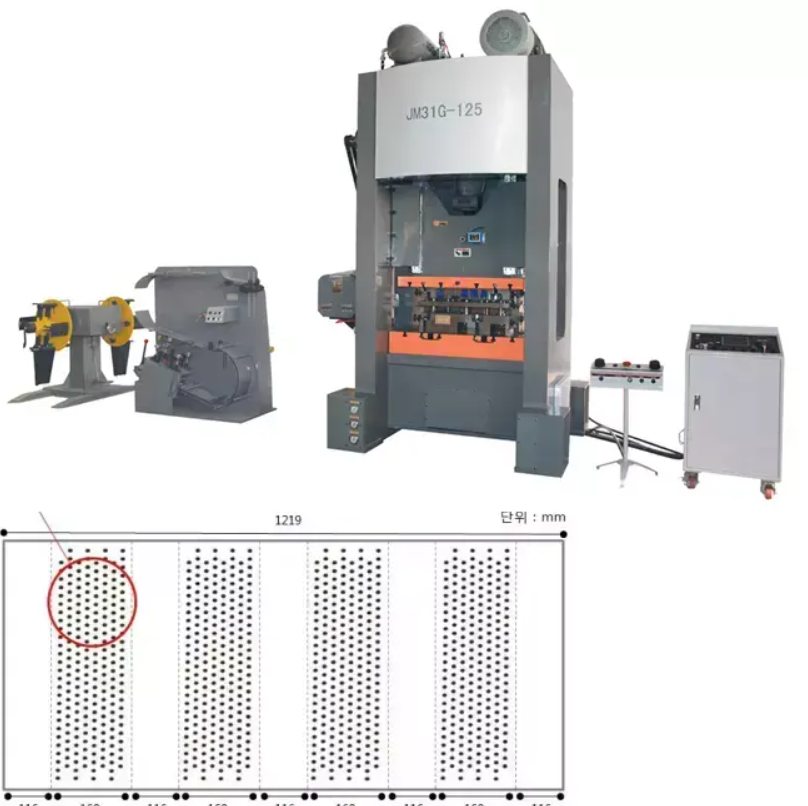

Manufacturing half round gutters involves various stages, including metal roll forming, cutting, and sometimes even the addition of decorative elements. The machinery needs to ensure that the gutters are uniform in size and shape, which is critical for proper installation and functionality.

Importance of Quality Machinery

The quality of the machinery used in the production of half round gutters significantly impacts the end product. High-quality machines produce gutters that fit perfectly, resist deformities, and handle the pressures of water flow without leaking. Furthermore, efficient machines can reduce manufacturing time, leading to quicker project turnarounds and reduced labor costs.

As demand for aesthetically pleasing and efficient rainwater systems continues to rise, many companies are investing in advanced technologies to enhance the precision of their gutter manufacturing processes. Modern machines often feature computer numerical control (CNC) capabilities, allowing for customized specifications and increased automation.

6 half round gutter machine companies

Leading Companies in Half Round Gutter Machine Production

1. Lefever Machine & Tool Known for its robust manufacturing techniques, Lefever Machine & Tool specializes in a range of gutter machines, including the 6% half round models. Their machines are praised for durability, precision, and high production speeds, making them a favorite among roofing professionals.

2. Rollforming Corporation This company is a significant player in the steel roll forming industry, offering innovative machinery that caters to the needs of half round gutter production. Their commitment to quality and customer service has earned them a strong reputation among contractors and manufacturers alike.

3. New Tech Machinery Renowned for its portable gutter machine solutions, New Tech Machinery provides a range of options that include half round models. Their emphasis on user-friendly operation and versatility allows contractors to efficiently produce high-quality gutters on-site.

4. Yoder Metal Forming A veteran in the industry, Yoder Metal Forming has spent decades refining its gutter production machines. Their 6% half round gutter machines feature advanced technology aimed at improving both efficiency and product quality, making them a trusted choice for many manufacturers.

5. Gutter Supply While primarily known as a supplier, Gutter Supply offers an extensive range of machines for gutter production, including half round options. They focus on providing tools that ensure precision and high throughput, catering to both small and large-scale production needs.

Conclusion

The importance of high-quality drainage systems cannot be overlooked in modern construction, and half round gutters stand out for their functional and visual benefits. Companies specializing in 6% half round gutter machines are pivotal in this industry, supplying manufacturers with the tools needed to produce effective and aesthetically pleasing solutions. As technology evolves, these companies continue to push the boundaries of what is possible in gutter manufacturing, ensuring that both contractors and homeowners have access to top-notch products that can withstand the test of time.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025