5v metal roofing machine company

Understanding the Importance of 5V Metal Roofing Machines in Modern Construction

In recent years, the construction industry has seen a surge in demand for durable and sustainable building materials. Among these, metal roofing has emerged as a preferred choice due to its robustness, longevity, and aesthetic appeal. At the heart of this trend are 5V metal roofing machines, which have revolutionized the way roofing panels are produced, helping to meet the increasing needs of builders and homeowners alike.

What is 5V Metal Roofing?

5V metal roofing, named after its distinctive five-v crimp design, is a popular style particularly in regions prone to severe weather. The shape of the roofing panels allows for effective water runoff, reducing the risk of leaks and water damage. This design is not only functional but also visually appealing, making it a favored choice for residential, commercial, and agricultural buildings. Made from materials such as galvanized steel, aluminum, and copper, 5V metal roofs offer exceptional resistance to rust and corrosion, ensuring they last for decades with minimal maintenance.

The Role of 5V Metal Roofing Machines

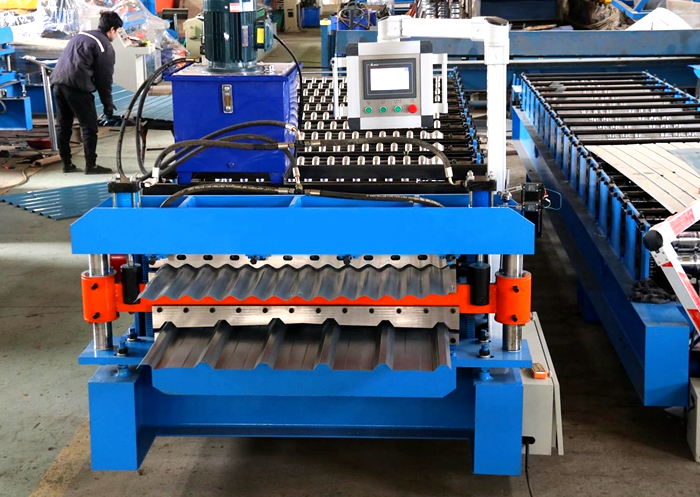

To meet the growing demand for 5V metal roofing, manufacturers have developed specialized machinery designed to produce these panels efficiently and accurately. 5V metal roofing machines are essential tools in modern manufacturing facilities, enabling producers to create high-quality roofing panels at scale. These machines can automate various processes, including coiling, cutting, and forming, leading to increased production speeds and reduced labor costs.

The use of advanced technology in 5V metal roofing machines ensures precise dimensions and consistent quality across all panels. Modern machines often come equipped with computer-controlled systems that enhance efficiency and accuracy in production. This precision is crucial, as even minor inconsistencies in panel size or shape can lead to installation challenges and potential leaks in the final product.

Benefits of Investing in 5V Metal Roofing Machines

5v metal roofing machine company

Investing in a 5V metal roofing machine can provide several advantages for manufacturers

1. Increased Production Capacity These machines allow businesses to significantly increase their output, meeting the demands of a rapidly expanding market. With the ability to produce large quantities of roofing panels in minimal time, companies can fulfill larger contracts and take on more projects.

2. Cost Savings Automating the production process reduces labor costs and minimizes waste material, leading to significant cost savings. Moreover, the durability of metal roofing materials can reduce long-term replacement and maintenance costs for customers, making the product appealing in the market.

3. Customization Options Many 5V metal roofing machines offer flexibility in customization, enabling manufacturers to produce panels in various colors and finishes. This ability to cater to customer preferences creates a competitive edge and enhances marketing opportunities.

4. Sustainability As environmental concerns continue to shape consumer choices, metal roofing stands out as an eco-friendly option. Many manufacturers utilize recycled materials, and the longevity of metal roofs means they contribute less waste to landfills over time. Investing in roofing machinery that allows for sustainable practices can improve a company's brand image and appeal to environmentally conscious consumers.

Conclusion

In conclusion, the rise of 5V metal roofing in the construction industry coincides with advancements in manufacturing technologies such as roofing machines. These machines not only boost production efficiency and quality but also align with the growing consumer demand for sustainable building practices. As metal roofing gains popularity, businesses equipped with the latest 5V metal roofing machines will be well-positioned to capitalize on this trend, ensuring they remain competitive in a rapidly evolving market. Investing in such technologies is not merely a business decision but a strategic move towards embracing the future of construction and sustainability.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025