Efficient 5V Metal Roofing Machine for High-Quality Roofing Solutions and Easy Installation

5V Metal Roofing Machine Revolutionizing the Roofing Industry

The demand for durable and aesthetically pleasing roofing materials continues to rise, and one product that has gained immense popularity is the 5V metal roofing system. The 5V profile, characterized by its unique design featuring five raised seams, is not only visually appealing but also offers exceptional performance in terms of durability and weather resistance. Central to the production of 5V metal roofing panels is the 5V metal roofing machine.

Understanding 5V Metal Roofing

Before diving into the specifics of the 5V metal roofing machine, it’s essential to understand what 5V metal roofing entails. The 5V designation refers to the configuration of five raised ribs that run vertically along the length of the panel. This design improves water runoff and provides resistance against the elements, making it an ideal choice for residential, commercial, and agricultural buildings.

5V metal roofs are typically made from galvanized steel or aluminum, offering superior longevity compared to traditional roofing materials. These panels can withstand harsh weather conditions, including heavy snow, strong winds, and rain, while also being fire resistant. Additionally, the lightweight nature of metal roofing contributes to easier installation and reduced structural load on buildings.

The Role of the 5V Metal Roofing Machine

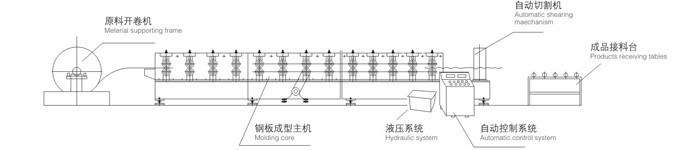

The 5V metal roofing machine is a specialized equipment designed to produce 5V metal roofing panels efficiently and with precision. The machine transforms metal coils into finished roofing panels, ensuring uniformity in quality and texture. There are several key components of the machine that contribute to its functionality

1. Uncoiler This component is responsible for unwinding the metal coil, which serves as the raw material for the roofing panels. It allows for continuous feeding of the coil into the machine.

2. Roll Forming Station The heart of the 5V metal roofing machine is the roll forming station. This is where the metal coil is shaped into the 5V profile. Multiple rollers bend the metal in a controlled manner to achieve the desired contours and dimensions.

3. Cutting Mechanism Once the roofing panels are formed, the cutting mechanism accurately trims them to specified lengths. This ensures that each panel meets the required measurements for installation.

5v metal roofing machine

4. Output Table After cutting, the finished panels are conveyed to the output table. This allows for easy collection and storage of the completed roofing products, ready for transportation to the job site.

Benefits of Using a 5V Metal Roofing Machine

Investing in a 5V metal roofing machine has numerous advantages for manufacturers and contractors alike

- Efficiency The machine automates the production process, significantly reducing labor costs and time. High-output capabilities allow manufacturers to meet rising market demands without compromising quality.

- Customization Many machines come with adjustable settings, allowing producers to customize panel lengths, colors, and even thicknesses to meet specific project requirements.

- Quality Control The precision engineering inherent in the machine ensures that each panel is consistent in dimensions and quality, reducing waste and enhancing customer satisfaction.

- Reduced Waste With accurate cutting and efficient production processes, the 5V metal roofing machine minimizes material waste, making the manufacturing process more sustainable.

Conclusion

In conclusion, the 5V metal roofing machine plays a vital role in modern roofing production. As the construction industry continues to evolve and emphasize sustainability, durability, and efficiency, the ability to produce high-quality metal roofing panels becomes essential. With the advantages offered by the 5V profile and the innovation of dedicated machinery, manufacturers can continue to meet the needs of a diverse market, enhancing the beauty and functionality of roofs across various applications. As the industry progresses, the 5V metal roofing machine will undoubtedly remain at the forefront of roofing technology, shaping the future of construction.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025