5 inch seamless gutter machine factory

The Importance of High-Quality Seamless Gutter Machines in Modern Construction

In the world of construction and roofing, seamless gutters play a pivotal role in managing rainwater and protecting buildings from water damage. With the increasing demand for durable and efficient drainage systems, the production of seamless gutters has become a critical aspect of modern architecture. At the heart of this process are seamless gutter machines, specifically the 5-inch seamless gutter machine, which are designed to facilitate the efficient manufacturing of high-quality gutters.

Understanding Seamless Gutters

Seamless gutters are continuous sections of guttering that are custom-made to fit the exact dimensions of a building. Unlike traditional sectional gutters that are joined together at various points, seamless gutters offer a more aesthetically pleasing appearance and significantly reduce the risk of leaks. This seamless design is particularly beneficial in regions prone to heavy rainfall, as it ensures optimal water flow and minimizes maintenance interventions.

The Role of Seamless Gutter Machines

The manufacturing of seamless gutters requires specialized machinery to create the seamless effect that sets them apart from traditional gutters. A 5-inch seamless gutter machine is specifically engineered to produce gutters that are 5 inches wide, a popular size among homeowners and contractors due to its balance of capacity and aesthetics.

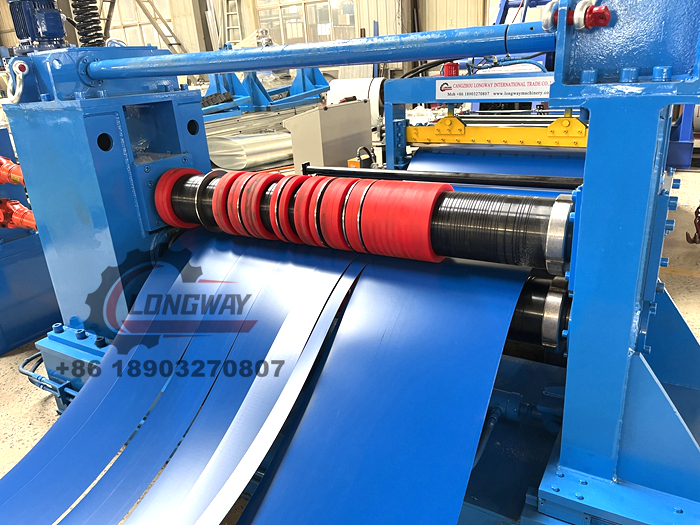

These machines operate by feeding a coil of material—commonly aluminum, galvanized steel, or copper—into a forming die, which shapes the material into the desired gutter profile. The precision of the machine guarantees that the necessary dimensions are met, resulting in products that fit perfectly and function smoothly. Moreover, these machines can produce gutters at an impressive rate, allowing for high-volume production which is essential for meeting market demands.

Benefits of Investing in a Quality Gutter Machine

5 inch seamless gutter machine factory

Investing in a high-quality 5-inch seamless gutter machine yields numerous advantages for manufacturers in the construction sector. First and foremost, quality machines enhance production efficiency. With faster operation speeds and minimal downtime, manufacturers can increase their output and better meet customer demands.

Additionally, precision engineering ensures that gutters produced are consistent in quality, promoting greater customer satisfaction. Seamless gutters manufactured with advanced machines exhibit better strength and resistance to weather elements, ultimately resulting in longer-lasting products. Businesses that prioritize quality can enhance their reputation and secure more contracts.

The Importance of Customization

One of the distinguishing features of modern seamless gutter machines is their ability to customize outputs. The 5-inch seamless gutter machine, for instance, can be adjusted to produce different profiles, enabling manufacturers to cater to various architectural styles and customer preferences. Customization plays a crucial role in maintaining relevance in a competitive market, allowing manufacturers to offer unique solutions tailored to specific projects.

Environmental Considerations

As sustainability becomes a central focus in construction, seamless gutter machines are also evolving to meet environmental standards. Many modern machines are designed to minimize waste and use recyclable materials, aligning with green building practices. Manufacturers who adopt eco-friendly methods not only contribute to environmental conservation but also attract a growing segment of eco-conscious clients.

Conclusion

The 5-inch seamless gutter machine is more than just a piece of equipment; it is a vital asset for manufacturers aiming to deliver quality, efficiency, and innovation in the construction industry. As the demand for seamless gutters continues to rise, investing in advanced machinery will enable producers to stay ahead of market trends, maintain high standards of quality, and fulfill the evolving needs of their clients. Ultimately, the choice to use seamless gutters and the machinery that produces them reflects a commitment to excellence in building practices, contributing to the longevity and environmental sustainability of our infrastructure.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025