3x4 downspout machine factory

The Evolution and Significance of the 3x4 Downspout Machine Factory

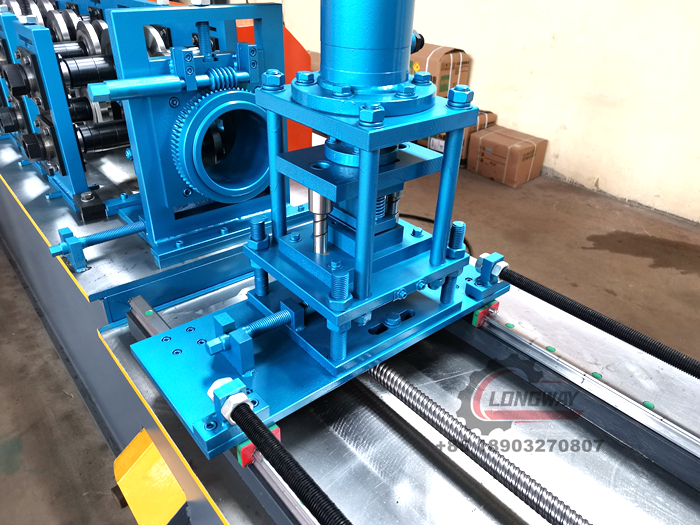

In the ever-evolving world of manufacturing, the production of downspouts has gained significant attention, especially with the introduction of specialized machinery such as the 3x4 downspout machine. This essential equipment has revolutionized the way downspouts are fabricated, providing efficiency, precision, and consistency in the manufacturing process.

Understanding Downspouts and Their Importance

Downspouts are vital components of a building's drainage system, collecting and directing rainwater from gutters away from the foundation. Properly functioning downspouts prevent water from pooling around the base of structures, thereby protecting them from potential water damage, erosion, and other structural issues. The 3x4 downspout, specifically, refers to the dimensions of the downspout, which measures three inches by four inches. This size is commonly used in residential and commercial buildings due to its optimal capacity for handling rainwater runoff.

The Role of the 3x4 Downspout Machine

The 3x4 downspout machine factory has emerged as a critical player in the construction and renovation industries

. By utilizing advanced technology, these factories are able to streamline the production process, significantly reducing the time and labor required to manufacture downspouts. The machines are designed to automate various steps, including cutting, shaping, and assembling the downspouts, which were traditionally done manually.Equipped with CNC (Computer Numerical Control) capabilities, the 3x4 downspout machines ensure precision in production, resulting in uniform products that meet industry standards. Each machine can be adjusted to accommodate various materials, including aluminum, vinyl, and steel, providing flexibility to manufacturers and allowing them to cater to a wider range of customer preferences.

3x4 downspout machine factory

Economic and Environmental Impact

The establishment of 3x4 downspout machine factories not only boosts local economies by creating jobs but also promotes sustainability. By producing downspouts in-house, manufacturers reduce shipping costs and the carbon footprint associated with transporting materials over long distances. Furthermore, the ability to reuse scrap materials generated during the manufacturing process contributes to a circular economy, minimizing waste and enhancing resource efficiency.

Future Innovations

As technology advances, the future of downspout manufacturing appears promising. Predictive analytics and AI integration are expected to further enhance production efficiency and quality control in 3x4 downspout machine factories. Innovations such as smart sensors can monitor the machinery's performance, predicting maintenance needs before they escalate into costly repairs, thereby ensuring smooth operations.

Conclusion

The 3x4 downspout machine factory plays a crucial role in modern manufacturing, significantly impacting the construction industry and the environment. By ensuring the efficient production of vital components like downspouts, these factories not only enhance building durability but also promote sustainable practices. As we move forward, the integration of advanced technologies will undoubtedly continue to shape the landscape of downspout manufacturing, paving the way for increased efficiency and innovation in this essential sector.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025