Jan . 13, 2025 14:39

Back to list

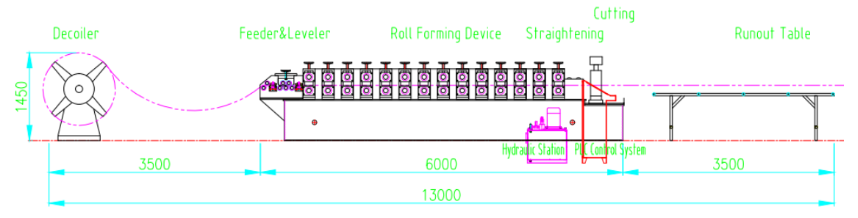

3 Rib Trapezoid roof sheet making machine

Understanding the complexities of the IBR roof sheet making machine is crucial for any manufacturing business aiming to enhance its production capabilities. The IBR roof sheet is a widely used building material, appreciated for its durability and effective coverage. Here, we take an in-depth look at what makes a top-tier IBR roof sheet making machine an indispensable asset for your industry, underscoring the Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T) crucial for this technology.

Authoritativeness in the industry stems from utilizing IBR roof sheet making machines that conform to international safety and quality standards. Aligning with globally recognized regulations assures clients of the product's quality and safety, boosting the manufacturer's reputation. Established brands with a proven track record in producing compliant machines are often preferred, as they offer peace of mind and reliability—key for businesses looking to secure their position in the market. Trustworthiness is built through consistently delivering products that meet or exceed customer expectations. An IBR roof sheet making machine that can reliably produce durable and meticulously shaped sheets contributes to building trust with clients. Moreover, investing in machines from reputable suppliers ensures access to dependable technical support and after-sales service, safeguarding the business from potential downtime and production losses. In conclusion, selecting an IBR roof sheet making machine demands careful consideration of its technological attributes, operational ease, material compatibility, and regulatory compliance. By prioritizing these aspects, a manufacturer not only optimizes their production line but also solidifies their standing in a competitive market. This strategic choice reflects a commitment to excellence and reliability, hallmarks of a sustainable and successful business operation.

Authoritativeness in the industry stems from utilizing IBR roof sheet making machines that conform to international safety and quality standards. Aligning with globally recognized regulations assures clients of the product's quality and safety, boosting the manufacturer's reputation. Established brands with a proven track record in producing compliant machines are often preferred, as they offer peace of mind and reliability—key for businesses looking to secure their position in the market. Trustworthiness is built through consistently delivering products that meet or exceed customer expectations. An IBR roof sheet making machine that can reliably produce durable and meticulously shaped sheets contributes to building trust with clients. Moreover, investing in machines from reputable suppliers ensures access to dependable technical support and after-sales service, safeguarding the business from potential downtime and production losses. In conclusion, selecting an IBR roof sheet making machine demands careful consideration of its technological attributes, operational ease, material compatibility, and regulatory compliance. By prioritizing these aspects, a manufacturer not only optimizes their production line but also solidifies their standing in a competitive market. This strategic choice reflects a commitment to excellence and reliability, hallmarks of a sustainable and successful business operation.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products