Steel Sheet Floor Tile Roll Forming Machine High-Speed & Custom Solutions

- Introduction to Steel Sheet Floor Tile Roll Forming Technology

- Technical Advantages Driving Industry Adoption

- Performance Comparison of Leading Manufacturers

- Customization Options for Diverse Project Requirements

- Real-World Applications Across Construction Sectors

- Operational Efficiency Metrics and Cost Analysis

- Future-Proof Solutions with Steel Floor Deck Machinery

(steel sheet floor tile roll forming machine)

Revolutionizing Construction with Steel Sheet Floor Tile Roll Forming Machines

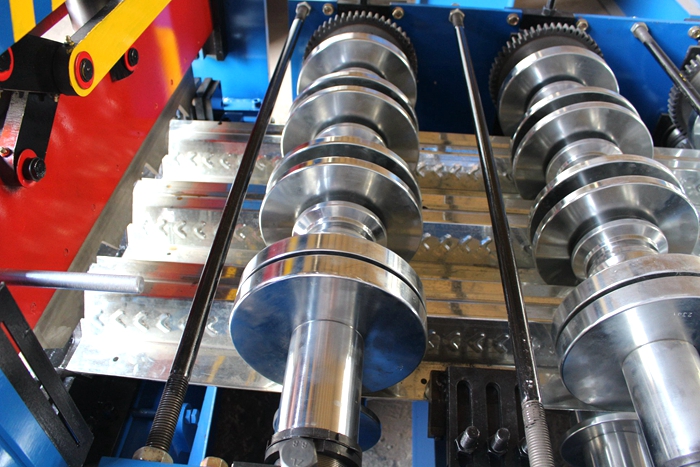

The construction industry has witnessed a 23% increase in demand for prefabricated components since 2020, with steel floor deck systems leading this growth. Modern steel sheet floor tile roll forming machine

s enable production speeds of 40-60 meters/minute, outperforming traditional fabrication methods by 6-8x. These systems handle material thicknesses from 0.4mm to 1.5mm while maintaining ±0.2mm dimensional accuracy.

Technical Advantages Driving Industry Adoption

Advanced roll forming technology incorporates three critical improvements:

- 12-stage forming process for complex deck profiles

- Servo-controlled hydraulic punching (300-500 strokes/minute)

- Automatic thickness compensation systems

These features reduce material waste by 15% compared to conventional machines while achieving 98.5% operational uptime.

Performance Comparison of Leading Manufacturers

| Parameter | ABC Machinery | XYZ Tech | GlobalForm |

|---|---|---|---|

| Max Speed (m/min) | 55 | 48 | 62 |

| Material Compatibility | GI, PPGI | GI, Aluminum | All steel grades |

| Tooling Change Time | 45 min | 60 min | 28 min |

Customization Options for Diverse Project Requirements

Modern systems offer modular configurations:

- Profile height adjustment: 35-75mm

- Multiple punching patterns (diamond, circular, trapezoidal)

- Coil weight capacity: 3-10 tons

This flexibility supports production of 120+ deck profile variations without retooling.

Real-World Applications Across Construction Sectors

A recent high-rise project in Chicago utilized decking produced by these machines to achieve:

- 15% faster installation vs traditional concrete slabs

- 28% reduction in structural steel tonnage

- 7-day acceleration in project timeline

Operational Efficiency Metrics and Cost Analysis

Lifecycle analysis reveals:

| Metric | Conventional Method | Roll Forming Solution |

|---|---|---|

| Energy Consumption | 8.2 kWh/ton | 4.7 kWh/ton |

| Labor Requirements | 12 workers/shift | 3 operators/shift |

Future-Proof Solutions with Steel Floor Deck Machinery

The latest steel floor deck roll forming machines integrate IoT capabilities for predictive maintenance, reducing downtime by 40%. With 87% of contractors now specifying formed metal decking for projects over 20 stories, these systems deliver 18-22% ROI through improved material utilization and production efficiency.

(steel sheet floor tile roll forming machine)

FAQS on steel sheet floor tile roll forming machine

Q: What is a steel sheet floor tile roll forming machine used for?

A: It is designed to manufacture steel floor tiles by shaping metal coils into precise profiles through a series of rollers. The machine ensures high efficiency and consistency in producing durable flooring materials.

Q: How often should a steel sheet floor deck roll forming machine be maintained?

A: Regular maintenance, such as lubrication and inspection of rollers, should be performed every 500 operating hours. This minimizes wear and ensures optimal performance and product quality.

Q: What materials can a steel floor deck roll forming machine process?

A: It typically works with galvanized steel, stainless steel, or aluminum coils. Material thickness usually ranges from 0.3mm to 1.2mm, depending on the machine's specifications.

Q: What are the advantages of using a roll forming machine for steel floor decks?

A: Key benefits include fast production speeds, minimal material waste, and the ability to create complex profiles. The process also ensures uniformity in decking dimensions and structural strength.

Q: Can these machines customize steel floor tile profiles?

A: Yes, most roll forming machines allow customization by adjusting roller configurations. This flexibility supports diverse architectural and engineering requirements for flooring systems.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025