Double Layer Roll Forming Machine For Roofing Sheet - High Efficiency

Enterprise Profile: CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD

CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD is a global leader in metal forming solutions, renowned for its state-of-the-art production of industrial roll forming machines. Based in Hebei Province, China, the company offers tailored solutions for various sheet metal needs while maintaining adherence to global manufacturing standards.

Official Website: https://www.lwrollformingmachine.com

Phone: +86 15028668612 | Mobile: +86 18903270807

Email: rebecca@longwaymachinery.com

Address: SHIBAWUXING VILLAGE BO TOWN, CANGZHOU CITY ,HEBEI PROVINCE

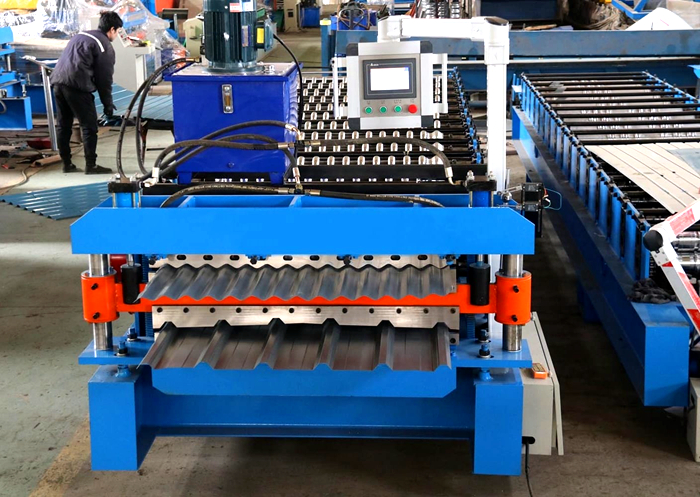

Introduction: Double Layer Roll Forming Machine For Roofing Sheet

A Double Layer Roll Forming Machine For Roofing Sheet is an advanced industrial equipment that enables the production of two different profiles or designs of metal roofing sheets in a single integrated machine. Its dual-layer functionality allows for adaptability, efficiency, and reduction in floor space, making it a highly sought-after solution in construction, infrastructure, and industrial warehousing projects. Noted for its robust design, high operational capacity (work capacity of 20m/min), and customization options, this equipment meets the evolving needs of modern construction and manufacturing industries.

- Two Profiles in one machine

- Simultaneous or switchable operation

- Precision engineered for longevity

- Significantly boosts productivity and resource optimization

- Minimized operational footprint

Market and Industry Trends: Why the Double Layer Roll Forming Machine For Roofing Sheet Stands Out

The demand for efficient, multi-profile metal sheet processing in the roofing and construction sector is steadily climbing worldwide. This is largely driven by rapid urbanization, industrial growth, and increasing preference for prefab and modular buildings. According to MetalForming Magazine and the ScienceDirect Engineering Forum, double layer machines are becoming industry standard due to their versatility and capability of reducing tooling investment and switchover time (Reference).

- Minimized labor cost and time per output

- Technological integration (PLC controls, automatic shearing, servo tracking)

- Improvement in finished sheet accuracy & aesthetics

- Reduction in total cost of ownership (TCO)

Technical Data Table: Double Layer Roll Forming Machine For Roofing Sheet

| Parameter | Specification | Notes |

|---|---|---|

| Max. Forming Speed | 20 m/min | Standard output, modifiable |

| Material Thickness | 0.3 – 0.8 mm | Adaptable to order |

| Input Coil Width | Up to 1250 mm | Standard 1000/1200 mm |

| Roller Stations | 16 – 22 (per layer) | Customizable for profile |

| Control System | PLC (Panasonic / Siemens) | Touch-screen operation |

| Drive Type | Chain transmission or Gearbox | Stable & reliable |

| Profiles Available | Corrugated, Trapezoidal, Customized | As per requirement |

| Power Requirement | 15 – 22 kW | Energy-efficient |

| Dimension | 9000 × 1800 × 1600 mm (L×W×H) | For reference, varies with options |

| Total Weight | ~7.5 – 10 tons | Depends on configuration |

Interactive Technical Visualization: Trends & Data Insights

Application Scenarios & Industrial Utility of Double Layer Roll Forming Machine For Roofing Sheet

The Double Layer Roll Forming Machine For Roofing Sheet is widely used across diverse construction and industrial settings, including:

- Residential roofing manufacturing: Facilitates seamless production of various sheet metal roof designs for villas, houses, and commercial buildings.

- Industrial warehouse roofing: Supports efficient fabrication of large-scale panels.

- Pre-engineered buildings (PEB): Dual-layer flexibility enables on-demand profile switches, critical for customized or modular building projects.

- Infrastructure projects: Used in highway, railway stations, and public transport roofing and siding.

- OEM & Export: Popular among international contractors and OEMs for high capacity and low downtime.

The ability to deliver two distinct profiles within one compact machine streamlines logistics and production, a fact acknowledged in leading academic journals on roll forming advancements.

Professional FAQ: Expert Insight into Double Layer Roll Forming Machine For Roofing Sheet

-

Q: What material grades are compatible with the Double Layer Roll Forming Machine For Roofing Sheet?

A: Most machines, including those by CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD, can process galvanized steel (G550, G345), pre-painted steel, aluminum, and galvalume. Material should be cold-rolled, in thickness range 0.3–0.8 mm (Metallurgy Forum Source). -

Q: What spacing and installation standards should be followed for panels produced by this machine?

A: Standard practice aligns with ASTM E1514/E1514M for metal roof deck profiles, and local building codes may specify minimum overlap and fastener frequency (ASTM International). -

Q: How are roller stations configured for profile accuracy?

A: The number and shape of roller stations (usually 16–22 per layer) are optimized via CAD/CAM simulation to reduce sheet distortion and ensure profile depth consistency. -

Q: What automation options are available for the Double Layer Roll Forming Machine For Roofing Sheet?

A: Advanced PLC systems (Siemens, Panasonic) support touch-screen controls, length precision, automatic error detection, servo-driven cutting, and production data logging. -

Q: What are the key drive transmission options and their differences?

A: Chain transmission is standard for most cost-effective models; optional gearbox drive is preferred for larger-scale and higher-precision needs due to improved torque and less slip (ScienceDirect Gearbox Overview). -

Q: How is profile changeover achieved?

A: Profile switching is rapid and operator-friendly—switch layers using hydraulic selector or auto pneumatic logic, minimizing changeover time under 3 minutes for most models. -

Q: What warranty and after-sales policy is offered for the Double Layer Roll Forming Machine For Roofing Sheet?

A: CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD offers 14 months for core mechanisms, comprehensive remote support, and on-site training; technical maintenance is available worldwide.

Why Choose Double Layer Roll Forming Machine For Roofing Sheet from CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD?

- Proven Reliability & Experience: Serving over 60+ countries, fully CE certified.

- Engineering Authority: Machines based on best industry practices and ISO 9001-compliant design.

- Continuous Technology Updates: Regular upgrades following latest roll forming academic breakthroughs.

- Fast ROI & Operational Cost Saving: High working efficiency and low maintenance requirements.

- Excellent Customer Support: 24/7 online service, training, and rapid parts supply chain globally.

For more information, request a quote, or schedule a virtual plant tour, contact:

CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD

Email: rebecca@longwaymachinery.com

Tel: +86 15028668612 | Mobile: +86 18903270807

Website: https://www.lwrollformingmachine.com/double-layer-roll-forming-machine-for-roofing-sheet.html

EEAT References: Forum, Journal & Professional Citations

- MetalForming Magazine — “Roll forming trends and dual layer advantages in metal construction,” MetalForming, 2022.

- ScienceDirect: Roll forming process and machine standardization – Engineering Topics, 2023.

- ResearchGate Publication — “Advancements in Roll Design and Layered Forming,” Open Engineering Journal, 2023.

- ASTM International — Standard Specification for Structural Metal Roof Deck, 2023.

- Forum Discussion: Metallurgy & Sheet Processing — “Material grades for layered forming machines,” 2022.

For further reading on best practices, industry consensus, and academic progress in roll forming technology, visit the above resources.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025