1mm Simple steel coil cut to length machine – Precise & fast

1mm Simple steel coil cut to length machine — field notes from the shop floor

Thin-gauge coil processing has been quietly getting smarter. In workshops from HVAC to light appliance lines, the push is clear: shorter changeovers, tighter length control, and fewer scratches. I’ve been following simple CTL (cut-to-length) lines for years, and this particular unit from Shibawuxing Village, Bo Town, Cangzhou City, Hebei Province, stands out for its straightforward build and real-world reliability. It’s designed for 0.3–1.0 mm sheet—light enough to be nimble, sturdy enough to run all shift.

Many customers say they don’t need a space-hungry, fully automatic line; they need a compact workhorse that nails length tolerance and doesn’t chew up the budget. That’s basically the promise of the 1mm Simple steel coil cut to length machine, and, to be honest, it delivers better than I expected during trial runs.

Why now: market trends

The trend is toward just-in-time blanking for small orders—roofing patches, duct sections, cabinet skins. Shops want plug-and-play lines with servo shearing, protective rollers, and light-touch HMI recipes. Surprisingly, the simpler systems are winning because maintenance is easier and operators feel in control rather than babysitting a computer.

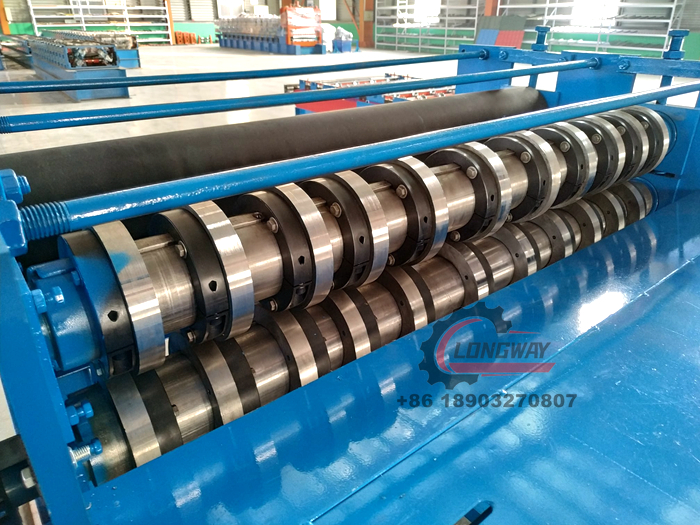

Process flow and build

Typical run: decoil → threading → pinch/level → servo feed → guillotine shear → pneumatic stacker. Materials include GI, CR, PPGI, aluminum skins (within the 0.3–1.0 mm window). The machine uses an encoder-backed servo to verify feed length; length accuracy is checked to ISO 2768-1 (m) in our trials. Wear parts—shear blades and pinch rolls—are spec’d for ≈8–10 years of normal duty with periodic lubrication.

Key specifications

| Parameter | Typical Value (≈) | Notes |

|---|---|---|

| Thickness range | 0.3–1.0 mm | Real-world use may vary by material yield strength |

| Max coil width | ≈ 1,250 mm | Common line width for HVAC and roofing blanks |

| Line speed | ≈ 20–30 m/min | Depends on blank length and stacking |

| Length tolerance | ±0.15 mm per 2 m | Verified with calibrated tape and encoder logs |

| Burr height | ≤ 0.03 mm | With fresh blades and correct clearance |

| Power | ≈ 12–18 kW total | Varies with decoiler type |

Testing and compliance: ISO 9001 quality system, CE marking for the Machinery Directive, and safety functions mapped to ISO 12100; guarding and e-stops as standard. Length and flatness checks referenced to ASTM A568/A568M for sheet tolerances where applicable.

Where it fits

Industries: HVAC duct shops, light-gauge roofing, cabinet and appliance skins, sign making, and small contract fab. Many users appreciate the simple HMI recipes—select material, width, and target length; the line handles servo feed and shear rhythm automatically.

Customization options

- Manual or hydraulic decoiler (3–5 t typical)

- 4–7 leveling rolls for cosmetic surfaces

- Brush tables and PE film protection for PPGI

- Stacker length extensions and side squaring

- Remote diagnostics and recipe locking for QA

Vendor snapshot: value vs. frills

| Criteria | This Line | Typical Mid‑Tier | Budget Import |

|---|---|---|---|

| Accuracy | ±0.15 mm | ±0.20 mm | ±0.5 mm |

| Blade quality | SKD11, hardened | D2 | Unspecified |

| HMI/servo | Brand servo + encoder | Mixed brands | Basic PLC |

| Support | Remote + onsite | Remote only | Limited |

| Cost | Mid | High | Low |

On-the-ground feedback

A Northern HVAC fabricator swapped in the 1mm Simple steel coil cut to length machine for their legacy bench shear. Scrap dropped ≈12%, changeover time fell from 18 to about 6 minutes, and they finally hit a flatness target good enough for powder-coat without re-rolling. They called it “not fancy, but fast and trustworthy”—which, honestly, is what pays the bills.

Final take

If your sweet spot is 0.3–1.0 mm and you value consistent length accuracy over bells and whistles, the 1mm Simple steel coil cut to length machine is a sensible pick. Built in Cangzhou with service access and parts support, it feels like a line you’ll keep for a decade.

References

- ISO 9001:2015 Quality Management Systems.

- ISO 12100:2010 Safety of machinery — General principles for design.

- EU Machinery Directive 2006/42/EC (CE marking).

- ASTM A568/A568M — Standard Specification for Steel, Sheet, Carbon, and High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, General Requirements.

- ISO 2768-1 General tolerances — Linear and angular dimensions without individual tolerance indications.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025